Table of Contents

- Why Corrosion Is the Silent Killer of Your Infrastructure

- How does modern cathodic protection work?

- New technical revisions to API 651 and AMPP SP0193

- Technical experience at the Burmah Oil terminal Bahamas

- Which is more expensive: advanced PC or total failure?

- IoT and Machine Learning in Cathodic Protection

- From theory to practice

- Why Act Now?

- The NISTM Call

- Conclusions

- References

Did you know that more than 2.5 trillion dollars are lost globally each year due to corrosion in storage tanks? As energy companies urgently seek sustainability, operational efficiency, and cost reduction in critical infrastructure, there’s a proven technology transforming asset integrity: advanced cathodic protection under the new API 651 and AMPP SP0193 standards.

In the era of energy transition, every barrel counts and every leak is not only an economic loss but also an environmental disaster. Mastering these technical revisions is not optional; it’s a matter of corporate survival. Aboveground Storage Tanks (ASTs) are the beating heart of terminals, refineries, and industrial storage plants, and a catastrophic failure can cost lives, reputation, and hundreds of millions in environmental remediation.

Why Corrosion Is the Silent Killer of Your Infrastructure

The main enemy of any asset, especially a storage tank, is corrosion. Every second, millions of steel atoms dissolve from the bottom plates of tanks that store petroleum, chemical, and fuel products. According to NACE International (now AMPP), the global cost of corrosion exceeds 3.4% of the world’s GDP, and aboveground storage tanks are among the most vulnerable sectors (Koch et al., 2016).

Most operators never see the problem until it’s too late: a dark stain spreading on the ground, leak detection alarms going off, or worse—a structural collapse that makes international headlines.

Why is corrosion in tank bottoms aggressive?

The answer lies in basic electrochemistry. When the steel bottom of a tank comes into contact with water, soil moisture, or electrolytes, a natural galvanic cell is formed. Iron acts as the anode, oxidizing and releasing electrons that flow to cathodic areas, forming iron oxide (rust) (Revie & Uhlig, 2008). This invisible electrochemical process gradually reduces the metal until it creates perforations that compromise the tank’s integrity.

The updated API 651 “Cathodic Protection of Aboveground Petroleum Storage Tanks” and AMPP SP0193 (formerly NACE SP0193) are now the industry’s most sophisticated responses to this lethal challenge. Published between 2022 and 2024, these standards incorporate decades of research in materials science, remote monitoring, and intelligent protection systems, redefining how we safeguard multi-billion-dollar assets (API, 2022; AMPP, 2023).

How does modern cathodic protection work?

Imagine being able to stop time for steel. That’s essentially what cathodic protection (CP) does: it turns the entire metal surface of a tank bottom into a cathode, where corrosion becomes thermodynamically impossible. But here lies the difference between obsolete systems and cutting-edge solutions: precision in design and system adaptability.

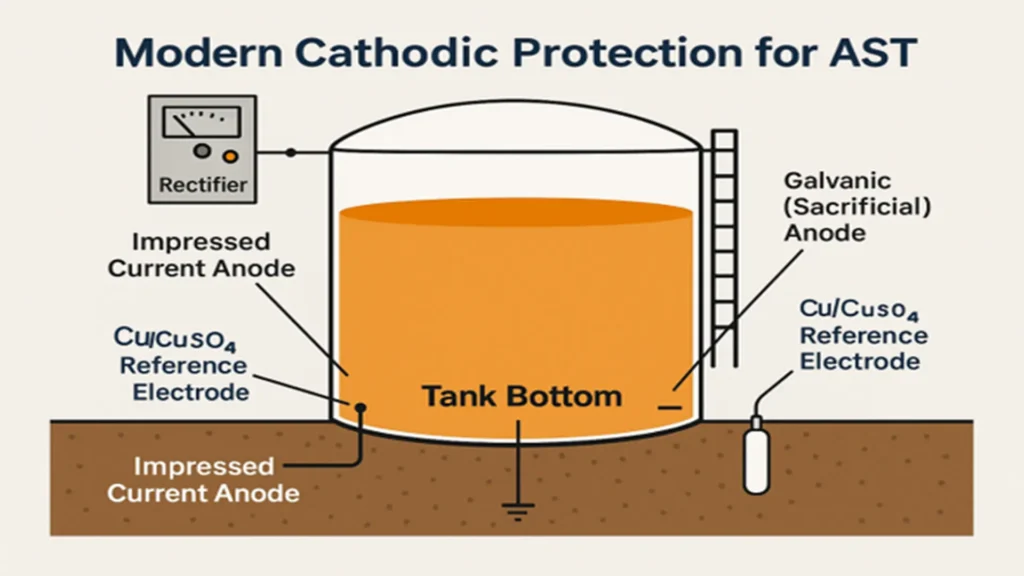

There are two main cathodic protection methodologies for AST tanks: impressed current cathodic protection (ICCP) systems and galvanic sacrificial anodes. ICCP systems use an external DC current source (rectifier) connected to inert anodes—usually titanium coated with mixed metal oxides—that inject electrons into the bottom of the tank, polarizing it to specific protection potentials: typically -850 mV relative to a Cu/CuSO₄ reference electrode (CSE) (Barlo & Mytton, 2019).

New technical revisions to API 651 and AMPP SP0193

The first thing to note is that the most significant updates include, for example:

- Updated protection criteria – The traditional -850 mV CSE criterion is no longer universal. Alternative criteria based on at least a 100 mV negative potential shift from the natural corrosion potential, validated through polarization tests, are recognized (AMPP, 2023).

- Continuous monitoring requirements – Remote monitoring systems must log data at least every 24 hours, allowing early detection of failures before corrosion damage occurs (API, 2022).

- Design based on real current density – New designs require multilayer soil resistivity studies, interference analyses, and accurate current demand calculations that consider coating efficiency, soil chemistry, and temperature (Broomfield, 2023).

- Integrity management integration – CP systems are now tied to Risk-Based Inspection (RBI) programs and API 653 compliance. CP is no longer a standalone system but part of an integrated asset management strategy (Morgan, 2021).

Technical experience at the Burmah Oil terminal Bahamas

It is worth recalling the case of an above-ground storage tank in the Bahamas, specifically at the Burmah Oil terminal (now owned by Buckeye Partners) on Grand Bahama Island, following Hurricane Dorian. In 2019, it faced a spill of 50,000 barrels due to corrosion failure at the bottom of a 100,000-barrel tank.

The investigation revealed that the cathodic protection system installed in 1995 had failed years ago without anyone noticing, as there was no remote monitoring. The total cost: $147 million in environmental cleanup, regulatory fines, and lost production (U.S. EPA, 2020). Often, the consequences of these incidents are not considered; but from the point of view of the undesirable event, the loss is in every sense.

Which is more expensive: advanced PC or total failure?

Installing a state-of-the-art impressed current cathodic protection system for an 80-foot diameter tank costs approximately $85,000 to $120,000. That includes a rectifier with SCADA remote monitoring, MMO titanium anodes, cabling, and permanent reference systems (Fitzgerald, 2023). Annual maintenance is approximately $3,000 to $5,000 for an estimated system life of 25-30 years.

But this contrasts with the cost of a failure: Environmental remediation alone is estimated to cost $2 million to $10 million (depending on volume and location). EPA/TCEQ regulatory fines range from $500,000 to $5 million. This does not include product loss, which could be between $300,000 and $2 million. However, there is something worse: the damage to reputation and loss of insurance is incalculable, in addition to the daily downtime of the asset, which, according to some industry estimates, would be in the range of $50,000 to $200,000.

“The ROI of a well-designed cathodic protection system is astronomical: for every dollar invested, between $50 and $150 is saved in avoided failure costs” (Palmer et al., 2020).

IoT and Machine Learning in Cathodic Protection

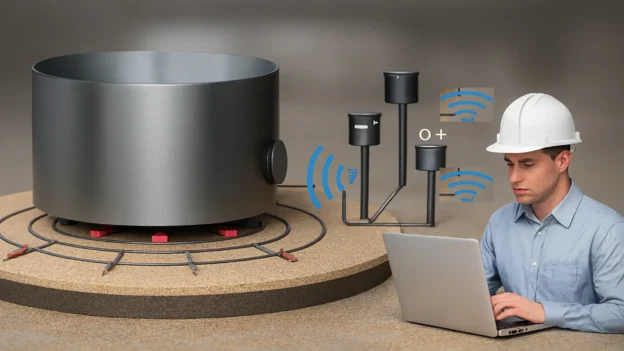

The most recent revisions to AMPP SP0193 are preparing the industry for the 4.0 revolution. Modern cathodic protection systems are no longer simply rectifiers connected to anodes: they are a universe of information that allows us to predict the performance and response capacity of assets. Figure 3 shows an engineer monitoring cathodic protection data using IoT systems and machine learning, demonstrating the integration of real-time remote monitoring and predictive analytics.

Henderson & Wang, in a 2024 publication, state that new-generation rectifiers incorporate 4G/5G cellular connectivity that transmits data in real time to cloud platforms. In this regard, facilities with the appropriate inspection technology feed machine learning algorithms by analyzing polarization patterns, identifying anomalies, and predicting imminent failures weeks before they occur. It should be noted that some systems can automatically adjust the output current according to seasonal changes in soil resistivity, optimizing energy efficiency while maintaining optimal protection.

The integration of drones equipped with electromagnetic sensors also maps CP effectiveness without the need for excavation or interruption of operations. These technologies, explicitly recognized in the AMPP SP0193 updates, are democratizing excellence in cathodic protection. It is no longer necessary to be a supermajor oil company to have world-class protection (Stephens, 2023).

From theory to practice

For engineers and managers, the decision to upgrade their cathodic protection (CP) systems is the first step in the environment in which they will work. It begins with a site assessment and characterization. This stage usually takes between two and four weeks to clearly define the scope of the project.

In this initial phase, detailed studies are carried out to determine the resistivity of the soil using the four-point Wenner method and to understand how the ground behaves in relation to electrical current. At the same time, the existing coating is carefully evaluated using holiday detection tests to identify the state and condition of the asset at any vulnerable points that could compromise the protection of the system.

With this information in hand, and adding the measurements between the structure and the ground, we move on to the next phase of the design, a process that usually takes between three and six weeks. At this point, the data obtained is integrated to develop a precise and durable technical solution, adapted to the specific conditions of the site.

Here, the focus is on accurately calculating the current requirements that determine the optimal configuration of anodes (distributed or centralized) and the sizing of the rectifier, to which a considerable safety factor must be added to ensure long-term protection against future degradation.

Once the design is finalized, the installation and commissioning phase begins (4-8 weeks), a process that requires the involvement of AMPP Level 3 certified inspectors to ensure adherence to the highest quality standards.

This stage culminates in rigorous acceptance testing, which is the functional verification of the new system and includes instantaneous-off potential surveys at multiple points and confirmation that protection criteria are met after a 48-hour polarization period, as well as calibration of remote monitoring systems. This step ensures that the system is correctly installed and operating at maximum capacity from day one.

Finally, cathodic protection becomes an ongoing and perpetual commitment to monitoring and optimization. This monitoring system begins with monthly review of potential trends through remote dashboards in a proactive management approach. Quarterly inspections of the rectifier and connections are complemented by comprehensive annual surveys conducted by a certified CP technician.

This long-term data forms the basis for the continuous adjustment of operating parameters, ensuring that the system not only complies with initial standards but also adapts to changing site conditions, guaranteeing uninterrupted structural integrity and maximizing the service life of critical infrastructure.

Why Act Now?

There is a general trend toward increased regulatory pressure (especially post-SB900 in Texas), and ESG expectations from investors and the availability of next-generation protection technology have also been created. Companies that proactively adopt the updated API 651 and AMPP SP0193 standards protect assets and build a competitive advantage.

Regulators are increasing the frequency of inspections and the severity of fines. Taking the state of Texas as an example, the Texas Commission on Environmental Quality (TCEQ) now requires more detailed documentation for ASVS registration to ensure more rigorous oversight of tank conditions and associated maintenance practices.

On the other hand, the U.S. Environmental Protection Agency (EPA) is currently evaluating the inclusion of cathodic protection as a mandatory requirement within the update of the SPCC (Spill Prevention, Control, and Countermeasure) program, which regulates spill prevention and control in certain types of tanks (U.S. EPA, 2024).

Given this scenario, it is clear that companies that do not yet have the cathodic protection systems required for the functioning and operation of their assets will face increasing barriers. More importantly, in an industry where margins are squeezed and every asset must justify its existence, extending the useful life of tanks from 20 to 40+ years through effective cathodic protection represents tangible value creation. A $3 million tank that lasts 40 years instead of 20 effectively doubles the return on investment on that capital.

The NISTM Call

The National Institute of Storage Tank Management (NISTM) is an organization dedicated to the liquid storage tank sector to foster and create spaces for learning, updating, and knowledge exchange among professionals, promoting safer, more efficient, and responsible management of these types of facilities.

But NISTM also focuses on disseminating best practices related to the operation, safety, and regulatory compliance of storage tanks, both aboveground (AST) and underground (UST). Through its activities, it seeks to strengthen the culture of prevention, improve equipment integrity, and ensure continuity of operations in a sector where safety and sustainability are fundamental.

To achieve this, experts, regulators, and service providers come together to analyze the latest advances, challenges, and changes in industry regulations. It also offers specialized programs and workshops that help companies and professionals update their knowledge, adapt to new technologies, and maintain high standards of quality and safety in storage tank management.

This is where best practices, case studies, and proposals for modifying and drafting addenda or appendices arise to complement the standards established by other organizations such as API and AMPP, and the best example is the update we have referred to in these lines.

Conclusions

The updated API 651 and AMPP SP0193 standards for cathodic protection are not simply a technical practice. It is an asset management philosophy that recognizes that critical infrastructure deserves intelligent, proactive, data-driven protection. For example, for professionals who meet annually at the NISTM conference, the message is clear: the era of “wait and repair” is over because the era of “predict and prevent” is here.

The tanks we install and protect today may still be operating safely in 2075 contributing to the potential development of an energy economy we cannot yet fully imagine. Our responsibility is to ensure they get there.

References

- AMPP. (2023). SP0193-2023: External cathodic protection of on-grade metallic storage tank bottoms. Association for Materials Protection and Performance.

- API. (2022). API Standard 651: Cathodic protection of aboveground petroleum storage tanks (5th ed.). American Petroleum Institute.

- Barlo, T. J., & Mytton, J. W. (2019). Design and operational considerations for cathodic protection of large diameter storage tanks. Materials Performance, 58(4), 42-48.

- Broomfield, J. P. (2023). Corrosion of steel in concrete: Understanding, investigation and repair (3rd ed.). CRC Press.