Table of Contents

The API 610/ISO 13709 standard, also known as the international standard for centrifugal pumps in the oil, petrochemical, and natural gas industries, serves a fundamental purpose in ensuring safety, performance, and reliability. This standard establishes rigorous requirements for the design, construction, and performance of this type of pump, with the aim of ensuring its suitability for the demanding operating environments within the oil and gas industry.

API 610 is a technical standard developed by the American Petroleum Institute (API), which establishes the minimum requirements for the design, manufacture, and testing of centrifugal pumps used in the petroleum, petrochemical, and natural gas industries.

This standard is widely recognized and accepted in the industry due to the influence and technical expertise of this organization in the oil and gas sector.

The standard establishes detailed requirements for key aspects of pump design and manufacture, including materials, dimensions, tolerances, and testing methods. In addition, the standard also addresses aspects related to mechanical seals, lubrication systems, cooling systems, and other critical pump components.

What is API 610 and how does it improve centrifugal pumps?

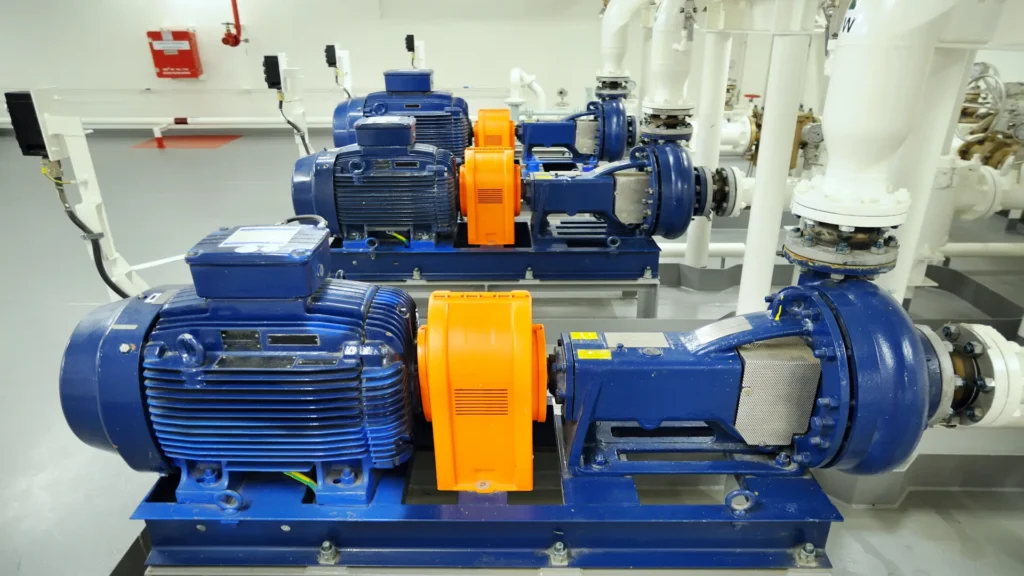

The API 610 standard specifies the requirements for centrifugal pumps used in refinery, oil and natural gas, petrochemical, and other industrial processes.

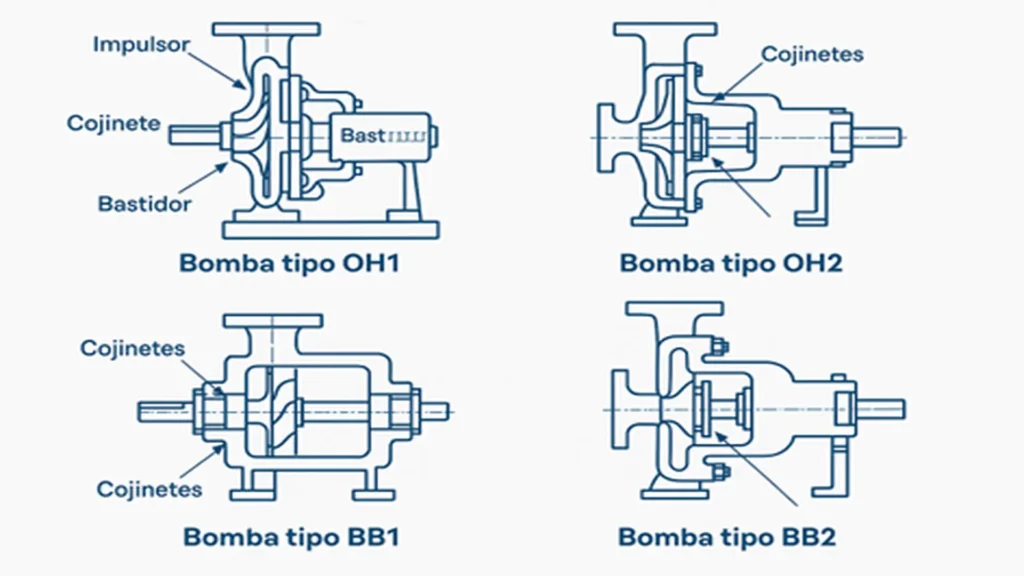

The following table provides technical content that delves into the types of API 610 pumps, detailing their configurations, technical characteristics, and common applications, with the aim of providing a highly technical resource for engineers and specialists in the field.

| Type | Configuration | Technical Description |

|---|---|---|

| OH1 | Horizontal, overhung, back pull-out | Impeller mounted directly on the motor shaft. Simple design, easy to maintain, ideal for general services. |

| OH2 | Horizontal, overhung, center supported | Impeller mounted on a shaft supported by bearings. More robust and suitable for high hydraulic loads. |

| OH3 | Vertical, closed shaft | In-line pumps with vertical casing. The motor and pump are vertically aligned. |

| BB1 | Horizontal, axially split casing | Double suction pumps, ideal for high flow rates. Axially split casing facilitates maintenance. |

| BB2 | Horizontal, single-piece casing | Robust configuration for higher pressures than BB1, with independent bearings. |

| BB3 | Horizontal, multistage, axially split casing | Used for high-pressure services, multistage and relatively easy to maintain. |

| BB4 | Horizontal, multistage, radially split casing | Compact design, ideal for high pressures and temperatures. |

| BB5 | Horizontal, multistage, double casing | Highly robust, used in critical and severe services such as boiler feed. |

| VS1 | Vertical, open shaft, overhung | Submerged type, ideal for wells or vertical pumping services with columns. |

| VS2 | Vertical, closed shaft, overhung | Similar to VS1 but with closed shaft. Better alignment and deflection control. |

| VS4 | Vertical, open shaft, column with intermediate support | Designed for deep sumps or gas-laden liquids. |

| VS6 | Vertical, multistage, barrel casing | High pressure, ideal for deep wells or water injection services. |

Advantages of API 610 (ISO 13709) in oil and gas

- Reliability: Pumps aligned with the API 610/ISO 13709 standard are designed to offer exceptional reliability, ensuring consistent pump performance even under extreme operating conditions.

- Safety: They are designed to meet rigorous safety requirements, contributing significantly to the overall integrity of facilities in the oil, petrochemical, and gas sectors.

- Efficiency: The standard places special emphasis on the efficiency of centrifugal pumps, promoting optimized energy use and the resulting reduction in operating costs.

- Compliance: It ensures adherence to industry regulations and best practices, providing a guarantee of quality and performance.

- Customization: Manufacturers offer the ability to customize pumps to suit specific operational requirements while maintaining compliance with established standards.

- Performance Testing: Pumps manufactured to this standard undergo rigorous testing, applying best practices and ensuring that they meet performance requirements and criteria.

- Versatility: This equipment is suitable for a wide range of applications within process services in the oil, petrochemical, and gas industries, demonstrating versatility and adaptability to various operational needs.

API 610 standard update: What’s new 2021 edition

Whenever a new edition of global specifications, such as those established by the International Organization for Standardization (ISO) and the American Petroleum Institute (API), is introduced, confusion arises around the detailed understanding of the key changes and the reasons behind them.

This article addresses some areas of modifications that directly affect the asset management, reliability and operational safety of pumps, highlighting the changes incorporated into the standard in Edition 12.a , Centrifugal Pumps for the Petroleum, Petrochemical and Natural Gas Industries, published in January 2021.

The documents are typically updated in 5-year cycles. The 12th edition of API 610 was released in January 2021, approximately 11 years after the publication of the 11th edition, primarily due to key elements that required additional time for resolution.

The working group began this update process in 2006, addressing the latest developments in rotating equipment, reliability issues, industry challenges and proposed changes based on sound and proven engineering and operating practices.

Reliability improvements according to API 610 (12th edition)

The 2021 edition (12th edition) of API 610 introduces important updates aimed at improving the reliability, predictive maintenance and energy efficiency of centrifugal pumps. The most significant changes include:

- New Annex O: Introduces specific guidelines for special purpose pumps, including high energy applications.

- Introduction of API RP 691: This new recommended practice addresses risk-based machinery management, optimizing predictive maintenance and operational safety.

- Updated design criteria: Fundamental requirements related to service life, hydraulic selection and pump data sheets were modified.

- Improved bearing selection: New criteria incorporate energy density for pipeline pumps, as well as specific limits for bearing and casing oil temperatures.

- Optimization in unit packaging: Improvements include shaft protectors, new baseplate designs for OH pumps, better arrangement of ancillary equipment and structural reinforcement in piping.

- Annex on special pumps (high energy): Clearly defines which pumps fall into the special purpose category, eliminating the ambiguity that existed in previous editions.

- New informative annex: Contains clear technical definitions, updated selection criteria, specific design considerations, materials, manufacturing and testing guidelines.

Pumps are one of the most widely used machines in process installations and piping systems. While industry standards and practices cover the design, installation and operation of pumps, but there was no general industry guidance on repair practices.

In this context it is important to note that the American Petroleum Institute has published a first edition standard, API Recommended Practice (RP) 697, Pump Repair2.

What is API 610 certification?

API 610 certification is an international standard developed by the American Petroleum Institute (API) that establishes minimum requirements for the design, manufacture and testing of centrifugal pumps used in the petroleum, petrochemical and natural gas industries. Its main objective is to ensure the safety, reliability and efficiency of this equipment in demanding industrial environments.

- The F-1 turbo pumps used on the Saturn V booster rocket engines are single-stage, high-speed pumps that operate at 5490 rpm and are designed for hydrogen and oxygen handling.

- High-pressure water injection pumps, which operate at 6000 rpm and generate 500 bar (7500 psi) of pressure, have the capacity to generate 500 m (1600 ft) of pressure rise per stage.

- Pipeline pumps used in the ethylene industry are designed to operate at high pressure.

- High-pressure boiler feedwater pumps are used to supply water at high pressure in boiler systems.

- Non-sparge refinery charge pumps, rated from 3 MW to 4 MW (4000 HP to 5400 HP), are used for charge pumping in refineries. Although special purpose pumps represent only about 1% of total pumps, they present significant challenges to designers and require special design considerations.

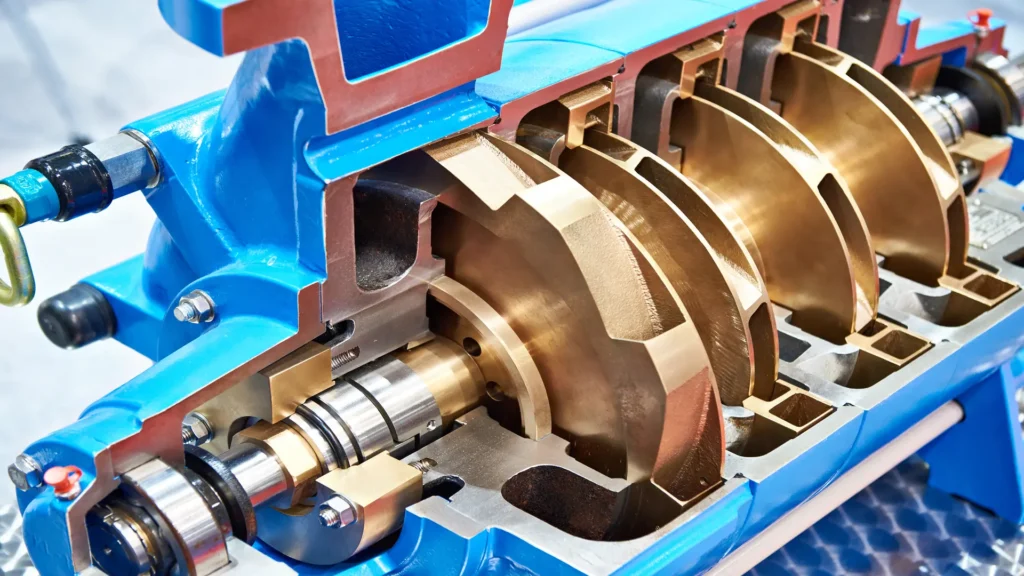

In high-energy pump engineering, every aspect of the design requires careful review. This includes rotor stiffness, distribution of residual stresses on metal-to-metal sealing surfaces, determination of deflection at critical settings, and establishment of proper operating clearances.

It is essential to perform a structural analysis of impellers and diffusers (or volutes) and determine the proper net positive suction head (NPSH) clearance in order to ensure pump operability and energy efficiency.

The following technical contribution summarizes the main modifications and requirements introduced by API 610 in its 12th edition, providing practical guidance for professionals involved in the design, operation and maintenance of industrial centrifugal pumps:

1. Performance curves

API 610 (12th Ed.) requires that performance tests be performed in accordance with HI 14.6 or ISO 9906. The test protocol is expanded from 6 to 9 mandatory points, all within the allowable operating region.

NPSH testing must include determination of NPSH₃ at points 2, 5, 6, 7 and 8, with H vs. NPSH(A) curves. The final flow rate should reach 120 % of BEP and the H-Q curve should be upward from the nominal point to the shut-off. The increase in measurement points may extend test and delivery times.

2. Base plates and protectors

| Element | Technical Requirement (API 610) | End User Considerations |

|---|---|---|

| General Design | Monolithic baseplates designed for grouting. | User must specify type (a) to (f). |

| Configuration Options | (a) to (f), including non-grouted versions and those with AVM or gimbal mounts. | Relevant for metallic structures such as FPSOs. |

| Drain Trough | Slope ≥ 1:120 towards the pump; minimum NPS 2 (DN 50) threaded connection. | Flanged connection should be clarified in the bid. |

| Grout Holes | At least one hole ≥ 125 cm² free area. | Specify if not required for steel structure mounting. |

| Restrictions for OH2 | Do not mount equipment over coupling or bearing housing. | In limited spaces, deviation may be requested. |

| Material for Low T | Standard structural material if T < -29°C. | Impact testing required if specified. |

| Guards | Vented and allow visual inspection of the seal without disassembly. | Accessibility must be verified after installation. |

3. Bearings and housing

| Technical Aspect | Standard Requirement | Remarks |

|---|---|---|

| Temperature Monitoring | Incorporate sensors to measure bearing metal temperature. | Facilitates predictive maintenance. |

| Lubrication | Constant level oiler with housing ventilation (balanced oiler). | Ensures stable lubrication level and pressure. |

| Drainage | Transparent reservoir with spring-loaded drain valve in the oil sump. | Allows removal of contaminants such as water or particles. |

| Lubricant Type | Mineral oil according to ASTM D4304 or ISO 8068 Type AR (unless otherwise specified). | Specify if another fluid is required. |

API 610 vs. ANSI B73.1 Pumps: Key Differences

While ANSI standards refer to dimensional standards, the API standard refers to the pump’s construction, design and ability to withstand high temperatures and pressures:

- API 610 pumps: this standard is specifically intended for pumps used in the oil, gas and petrochemical industries. Its focus is on pumps designed for handling hydrocarbons, corrosive fluids, as well as applications involving high temperatures and pressures.

- ANSI B73.1 Pumps: Also known as ASME B73.1, this standard covers horizontal end suction centrifugal pumps designed for general purpose applications. Their primary application is in industrial and commercial settings, where the handling of water, chemicals and other less rigorous fluids is required.

These fundamental differences ensure that each standard is precisely tailored to the specific demands of their respective applications, addressing particular needs in terms of corrosion resistance, extreme condition capability and fluid handling requirements, ensuring their performance.

API pumps are recognized for their heavy-duty capability compared to ANSI pumps. These differences are evident in the characteristics of the casings, bearing housings, anchor feet and back cover arrangement, which allow them to achieve efficient pumping control and demonstrate greater energy efficiency and pump reliability in recommended applications.

Conclusions

Adherence to API 610 is key for manufacturers and end users of centrifugal pumps, ensuring safe, efficient and reliable products. Applying this international standard allows reducing failures, improving operational performance and effectively adapting to the requirements of the oil, petrochemical and natural gas industries.

API 610 (ISO 13709 in its international version) establishes clear technical requirements for horizontal, vertical and cantilever centrifugal pumps, ensuring operational integrity, industrial productivity and compliance with environmental objectives.

Complying with API 610 not only optimizes equipment reliability, but also strengthens safety and sustainability in critical facilities in the energy sector. In a constantly evolving environment, implementation of this standard demonstrates commitment to operational excellence and driving best practices in the oil and gas industry.

References

- Shaker Heights Ohio, and R. Jones; “Online exclusive: API 610 12th edition addresses pump reliability and maintenance”; Hydrocarbon Processing, 20/01/2022 10:15:13, accessed 16 November 2023; https://www.hydrocarbonprocessing.com/news/2022/01/online-exclusive-api-610-12th-edition-addresses-pump-reliability-maintainability-and-more.

- American Petroleum Institute, API; API Recommended Practice (RP) 697, Pump Repair; first edition.

API 610 Frequently Asked Questions (FAQs)

What does API 610 mean?

API 610 is an international standard that specifies technical requirements for centrifugal pumps used in the oil, gas and petrochemical industries, ensuring high reliability and operational safety.

What is the latest version of API 610?

The latest update of API 610 is the 12th edition, published in 2021, and includes significant improvements in reliability, maintainability and energy efficiency.

For which industrial applications is API 610 recommended?

API 610 is recommended primarily for critical applications in the extraction, refining and transportation of oil, natural gas and petrochemical processes due to its high operational reliability.

What is the difference between API 610 and ANSI B73.1?

API 610 focuses on highly demanding critical applications in petroleum industries, while ANSI B73.1 is designed for less demanding applications and general industrial processes.

What are the benefits of complying with API 610 for centrifugal pumps?

Compliance with API 610 ensures greater operational safety, improved reliability, less unplanned maintenance, and extends the life of critical industrial equipment.

Is API 610 equivalent to ISO 13709?

Yes, API 610 is equivalent to ISO 13709; both standards are technically identical, with API 610 being the most widely used version in the Americas.