Asset integrity management (AIM) is a systematic approach to ensuring that physical assets in industries and the energy sector are maintained in safe and operational condition. AIM can help organizations improve the safety, reliability, efficiency and profitability of their assets. In recent years, artificial intelligence (AI) is revolutionizing AIM, providing new ways to collect, analyze and process data, as well as make decisions.

In this article we will talk about some practical applications of AI, its impacts on safety, profitability and efficiency, as well as the challenges and opportunities it presents. AI is no longer just a futuristic concept; It is the cornerstone upon which the next era of asset management is built.

How does AI operate in asset integrity management?

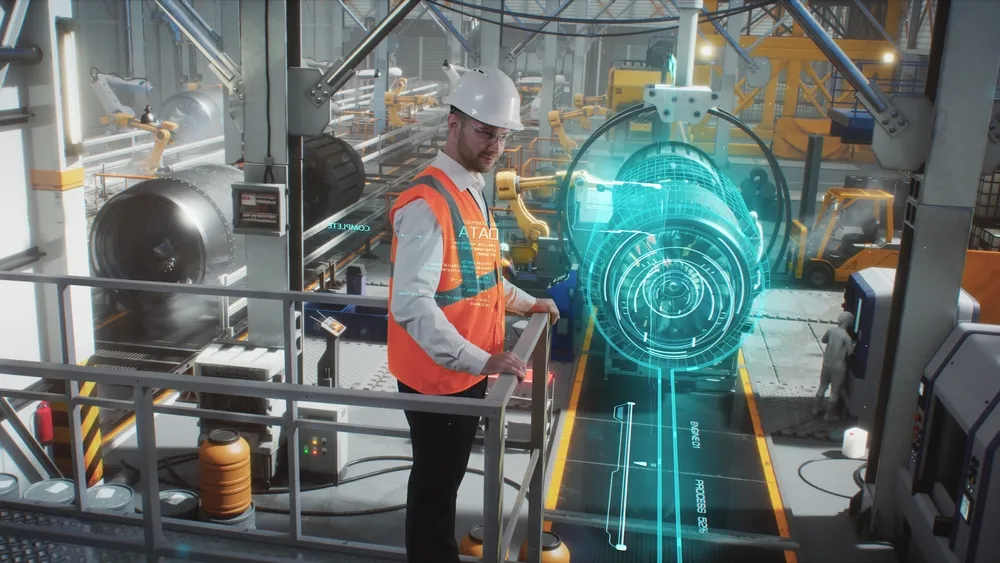

The merger between Asset Integrity Management (AIM) and Artificial Intelligence (AI) has completely changed the way organizations manage and maintain their physical assets. This technological symbiosis draws on data from multiple sources, including cutting-edge sensors, historical records and advanced imaging technologies.

AI applications in asset integrity management

Analyze images of equipment to detect damage

This technology allows organizations to identify and assess potential damage to critical assets quickly, accurately and non-intrusively.

Analysis process :

- Image Capture: Images of assets are captured using specialized cameras or mobile devices with high resolution.

- Identification of anomalies : AI algorithms process these images, looking for visual patterns that may indicate damage, such as cracks, corrosion or wear.

- Comparison with previous patterns : The AI compares current images with a database of historical patterns, learning to identify new anomalies and continually improving its accuracy.

Benefits:

- Accuracy: AI far exceeds human capabilities in detecting microscopic or subtle irregularities that might go unnoticed in conventional visual inspections.

- Response time : The processing speed of AI allows for an almost instantaneous response, which speeds up detection and action time in the face of potential problems.

- Preventing major damage : By identifying damage at early stages, progression to catastrophic failure is prevented, thereby reducing costs and downtime.

Application example :

In the oil industry, AI analyzes images of pipelines to detect incipient corrosion , allowing interventions before structural integrity is compromised.

Predicting when an asset needs maintenance

Artificial Intelligence (AI) has evolved asset management by accurately predicting when maintenance will be needed on equipment and facilities, enabling strategic planning and reducing unforeseen downtime.

Operation of the predictive process:

- Data Collection: AI analyzes a wide range of data, including sensor readings, historical maintenance records, and operating conditions.

- Machine Learning: Machine learning algorithms process this data, identifying patterns and correlations that indicate potential failures or maintenance needs.

- Predictive modeling : Based on these patterns, AI creates predictive models that calculate the optimal time to perform preventative maintenance.

Featured benefits:

- Cost reduction: By performing maintenance just when it is necessary, unnecessary expenses are avoided and the use of resources and spare parts is optimized.

- Increased availability: Predictive planning minimizes unplanned downtime, keeping assets operational and available when they are needed most.

- Resource Optimization: Accurate maintenance scheduling maximizes equipment efficiency and minimizes production interruptions.

Practical examples:

- In the aerospace industry, AI analyzes component wear to predict months in advance when specific parts will need to be replaced, avoiding flight interruptions.

- In power generation plants, AI constantly monitors the performance of turbines and generators, anticipating unscheduled shutdowns and optimizing production.

Optimize maintenance planning

AI has become a fundamental ally in transforming maintenance planning, allowing for more efficient and effective management of assets.

Strategic approach to AI:

- Predictive analysis: AI uses predictive models to anticipate maintenance needs, identifying optimal times for interventions.

- Intelligent prioritization: Based on real-time and historical data, AI prioritizes maintenance tasks based on their urgency and impact on operations.

- Optimal scheduling: By considering variables such as resource availability, downtime, and operational demand, AI creates efficient maintenance schedules.

Benefits:

- Reduction of costs and downtime : Accurate planning minimizes operating expenses by avoiding unnecessary interruptions and optimizing the use of resources.

- Greater operational reliability: By ensuring that maintenance is performed at the most appropriate times, asset reliability and availability is maximized.

- Improved productivity: Strategic maintenance planning allows teams to work more efficiently and focus on critical areas.

Practical examples:

- In the manufacturing industry, AI generates maintenance schedules for production lines, minimizing interruptions and ensuring continuous, efficient production.

- In wind farms, AI coordinates turbine maintenance considering weather conditions, guaranteeing the safety of technicians and maximizing the operating time of the equipment.

Manage spare parts inventory

AI in spare parts inventory management optimizes the availability of crucial components, minimizes costs and contributes significantly to operational efficiency and maintenance continuity. AI offers a more predictive and efficient approach

Optimized process:

- Demand Analysis: AI analyzes historical and real-time demand patterns to predict when and what parts will be needed in the future.

- Stock optimization: Based on predictive models, AI recommends optimal stock levels to avoid excesses or shortages, minimizing storage costs and waiting times.

- Automated order management: AI automates the generation and tracking of spare parts orders, streamlining the process and ensuring timely availability of necessary components.

Benefits:

- Reducing storage costs: By maintaining accurate inventory levels, costs associated with storing unnecessary parts are minimized.

- Preventing downtime : Proactive inventory management ensures the availability of crucial spare parts, avoiding maintenance delays due to missing parts.

- Resource optimization: By ensuring the fair availability of spare parts, financial resources are optimized and maintenance efficiency is maximized.

Practical examples:

- In the transportation sector, AI predicts demand for spare parts for vehicle fleets, ensuring that each unit has the necessary components to avoid unforeseen downtime.

- In production plants, AI manages the inventory of spare parts for key machinery, ensuring that critical parts are available at the right time, thus minimizing production interruptions.

Conclusion

In summary, artificial intelligence has not only transformed the way assets are managed in industries and the energy sector, but has also laid the foundation for smarter, more efficient and adaptable management in today’s business world.

“Discover how Artificial Intelligence can transform your asset management! Optimize, save costs and increase efficiency today.”