Table of Contents

- What Is PAUT and How Does This Advanced Ultrasonic Technology Work?

- PAUT vs. Conventional Ultrasonic Testing: Key technical differences

- Standards and codes governing the use of PAUT in industry

- Defectology detectable by PAUT inindustrial assets

- Industries where PAUT delivers the greatest operational value

- Recent technological advances in PAUT solutions

- Technical and operational benefits of PAUT compared to conventional UT

- Criteria forselecting appropriate PAUT equipment and solutions

- Conclusions

- References

- Frequently Asked Questions (FAQs)

The increasing requirements for reliability, availability, and operational safety in sectors such as Oil & Gas, energy, petrochemical, mining, and aerospace have driven the adoption of Non-Destructive Testing (NDT) technologies capable of characterizing internal defects with greater accuracy and speed. Within this context, industrial ultrasonic testing (UT), as part of the broader field of non-destructive testing, has evolved from conventional methods based on longitudinal and shear waves toward advanced solutions supported by digitalization, real-time signal processing, simulation, and multichannel visualization (Hellier, 2001; ASM International, 2004).

This modernization process has enabled Phased Array Ultrasonic Testing (PAUT) to become established as a critical tool for mechanical integrity management and for the detailed analysis of discontinuities in welds, joints, critical components, and assets subjected to mechanical stress, corrosion, or fatigue (ASM International, 2004; ISO 13588:2019).

The technological transition toward this technique is not driven solely by technical demand, but also by regulatory and operational change. Current industry codes, led by ASME, API, AWS, and ISO, require enhanced traceability, documented compliance, and stricter criteria for defect acceptance or rejection (ASME BPVC Section V, 2023; ISO 19285:2017). In parallel, plant turnaround cycles, Risk-Based Inspection (RBI) programs, and asset life-cycle management strategies have increasingly incorporated advanced ultrasonic techniques as a decisive factor in reducing uncertainty, minimizing unplanned costs, and preventing catastrophic failures.

This method has become particularly relevant in weld inspection of pipeline welds, pressure vessels, heat exchangers, aerospace components, and metallic structures subjected to dynamic loading. Its ability to generate sectorial scans, multi-angle cross-sections, and volumetric reconstructions significantly improves inspector interpretation and reduces the margin of error associated with traditional analog methods. As a result, industry has progressively shifted toward smarter, more integrated, and predictive inspection solutions, where PAUT serves as a bridge between conventional NDT techniques and the digital transformation of industrial inspection.

What Is PAUT and How Does This Advanced Ultrasonic Technology Work?

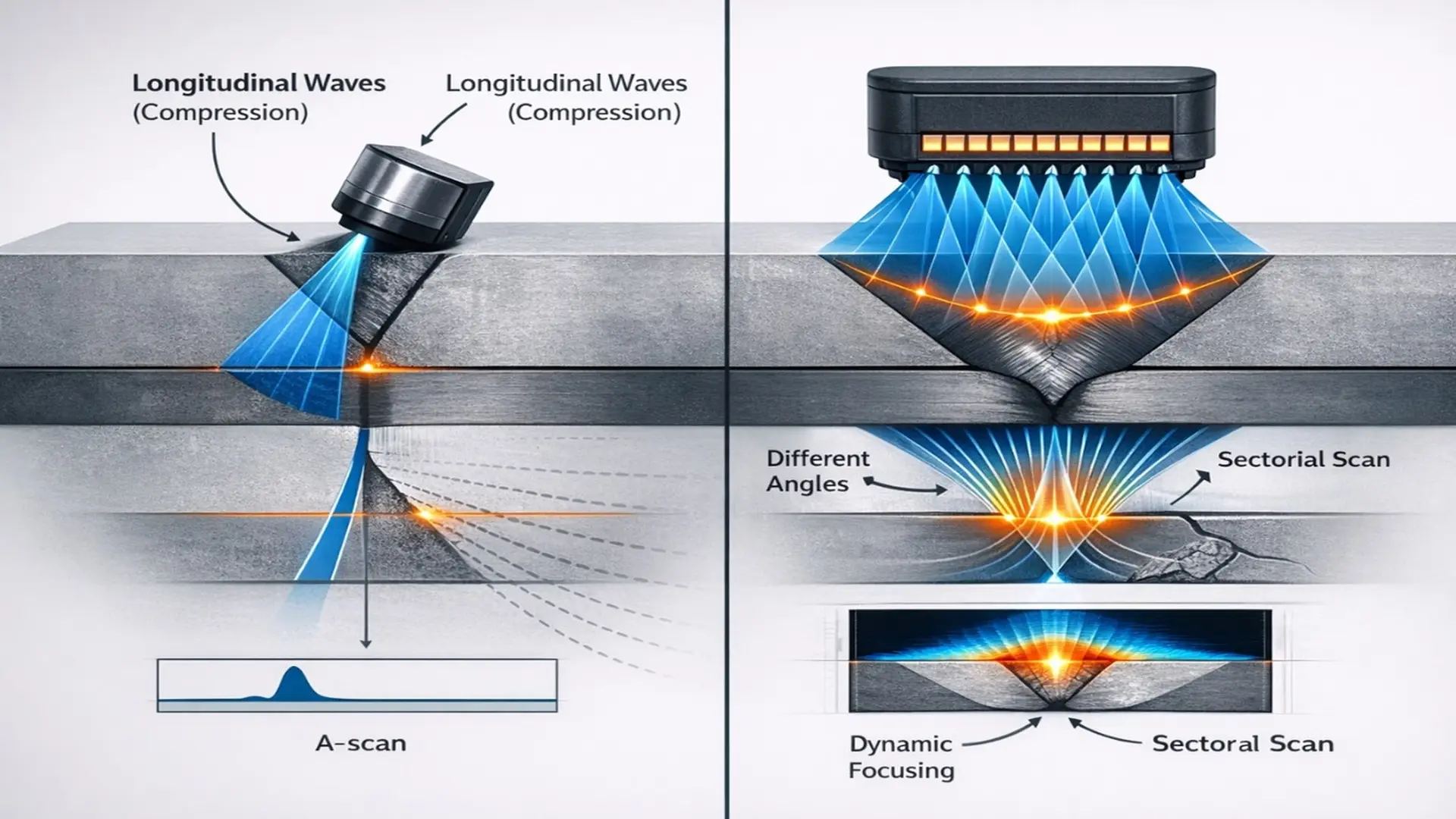

Phased Array Ultrasonic Testing (PAUT) is an advanced industrial ultrasonic technique that uses arrays of piezoelectric elements excited in a controlled sequence to generate, steer, and focus ultrasonic beams. Unlike conventional ultrasonic methods based on a single transducer, this method enables the creation of multiple angles of incidence and sectorial scans, allowing a volumetric visualization of the inspected area.

This capability significantly increases the Probability of Detection (POD), strengthening overall defect detection performance and improving the accuracy of internal defect characterization, particularly in welds, critical joints, and components exposed to corrosion or mechanical stress. From an industrial perspective, this technique represents a convergence of NDT, digitalization, modeling, and data analysis, making it a key tool for inspection during fabrication, repair, maintenance, and mechanical integrity management.

Physical Principles of Phased Array Ultrasonic Testing

The operation of this technique is based on four fundamental physical principles: wave propagation, beam focusing, delay laws, and sectorial or linear beam control. First, wave propagation describes how ultrasonic waves travel through the material, defining parameters such as velocity, attenuation, and wave modes (longitudinal, shear, or surface). Second, beam focusing is achieved through the sequential and controlled excitation of array elements, concentrating ultrasonic energy in specific regions to enhance spatial resolution and inspection sensitivity.

Third, delay laws make it possible to modify the firing time of each element to generate angled beams, sectorial scans, or focused profiles at different depths. Finally, the distinction between sectorial and linear scanning defines the type of volumetric coverage: sectorial scanning creates angular fans that facilitate the detection of oriented discontinuities, while linear scanning is better suited for more direct inspection paths. Together, these principles explain why PAUT overcomes the geometric and directional limitations of conventional ultrasonic testing, delivering a more robust and adaptable inspection method for complex geometries.

PAUT vs. Conventional Ultrasonic Testing: Key technical differences

When compared to conventional ultrasonic testing, this method offers significant improvements across five key technical dimensions: sensitivity, coverage, volumetric analysis, angular resolution, and inspection time. In terms of sensitivity and coverage, PAUT maximizes the interaction between the ultrasonic beam and the discontinuity through controlled focusing and angular scanning, significantly enhancing defect detection compared to a single fixed beam. For volumetric analysis, the reconstruction of sectorial (S-scan) and linear (E-scan) images allows defects to be viewed from multiple angles, supporting more accurate characterization.

Regarding angular resolution, this method can distinguish closely spaced or geometrically complex discontinuities with greater precision. In inspection time, the use of multi-angle scanning reduces repetitive probe movements and minimizes operator dependency. Finally, from a risk reduction standpoint, the use of digital images and software-assisted analysis decreases subjective interpretation, strengthening traceability and compliance with applicable codes and standards.

Suggested Comparative Table (for designer or AI image generation)

| Technical Parameter | Conventional UT | PAUT |

|---|---|---|

| Beam type | Single fixed beam | Electronic multi-beam |

| Coverage | Limited | Wide and sectorial |

| Visualization | A-scan | S-scan / E-scan |

| Volumetric analysis | No | Yes |

| Operator dependency | High | Reduced |

| Repeatability | Variable | High |

| Inspection time | Longer | Optimized |

| Traceability | Limited | Digital and auditable |

| Advanced code compliance | Partial | Optimal (ASME / ISO / API) |

Standards and codes governing the use of PAUT in industry

The use of Phased Array Ultrasonic Testing (PAUT) in industrial inspection is not driven solely by technological advancements or productivity demands; its adoption is strongly shaped by the regulatory framework governing the fabrication, repair, inspection, and acceptance of critical components. In sectors such as Oil & Gas, petrochemicals, power generation, aerospace, and nuclear, codes and standards impose specific requirements to ensure traceability, adequate sensitivity, test repeatability, and risk-based evaluation criteria.

This regulatory approach ensures that this method is not only capable of detecting internal discontinuities, but that it does so under verifiable and internationally comparable standards, supporting decision-making related to mechanical integrity, remaining life, and fitness-for-service assessments.

Applicable requirements of ASME Section V

ASME Section V represents the most widely referenced normative foundation for the application of this technique in pressure equipment, vessels, piping systems, and associated components. Within this code, the rules governing examination techniques, calibration practices, sensitivity levels, and inspection scope are defined to ensure traceable and objectively comparable results. Examination rules establish minimum requirements for equipment configuration, applicable procedures, scanning techniques (sectorial or linear), and the use of imaging for data recording.

Calibration requirements address the adjustment of equipment using reference blocks or calibration standards, ensuring that the ultrasonic response is proportional to the emitted energy and consistent with component geometry. Sensitivity requirements define the capability of the technique to detect defects of critical size, considering factors such as frequency selection, beam focusing, inspection angle, and material attenuation.

Finally, the scope of application specifies the conditions under which this method is acceptable as an inspection method, either replacing or complementing techniques such as industrial radiography (RT) or conventional ultrasonic testing (UT). In summary, ASME Section V formally integrates PAUT into fabrication and repair workflows, ensuring its application is both technically sound and regulatorily defensible.

Other Relevant Standards: API, ISO, AWS, Aerospace, and Nuclear

Beyond ASME, PAUT is governed by sector-specific standards that address operational requirements and acceptance criteria tailored to particular industries. API incorporates PAUT into inspections related to surface equipment, piping, vessels, and process plants, integrating the technique with Risk-Based Inspection (RBI) and Fitness-For-Service (FFS) methodologies. ISO standards harmonize terminology, equipment requirements, and procedures to ensure international compatibility.

AWS formalizes the use of this technique for weld inspection, defining acceptable discontinuities and evaluation criteria. In aerospace applications, standards demand higher levels of Probability of Detection (POD), repeatability, and technical documentation. In the nuclear sector, codes prioritize redundancy, reliability, and strict regulatory compliance due to the critical nature of the assets involved.

Defectology detectable by PAUT inindustrial assets

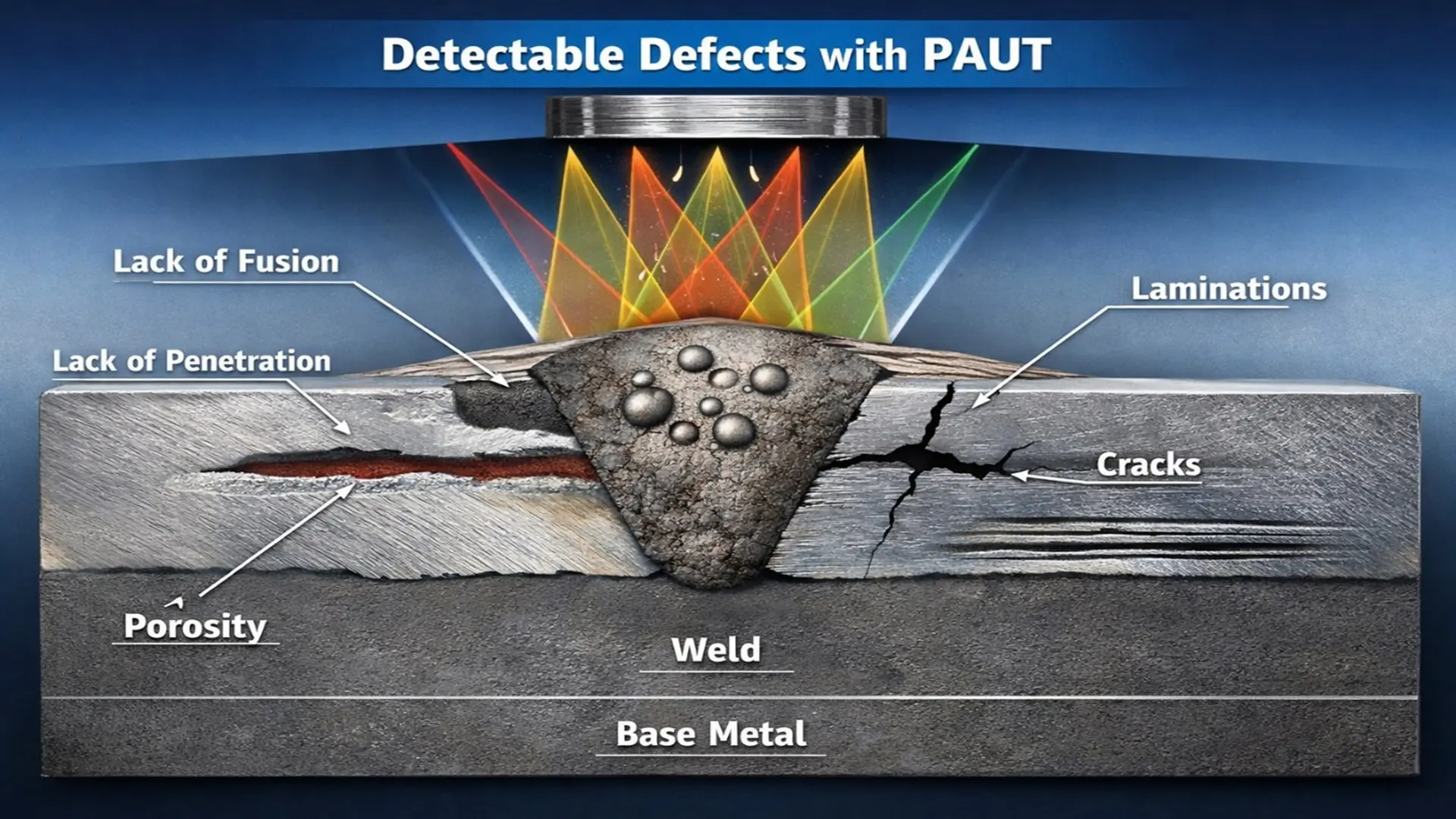

Phased Array Ultrasonic Testing (PAUT) has proven to be particularly effective in the identification, characterization, and sizing of internal discontinuities associated with welds, manufacturing processes, and in-service degradation mechanisms. Thanks to its ability to generate sectorial scans and volumetric reconstructions, this method allows inspectors to obtain multiple perspectives of a defect, including its orientation, location, amplitude, and extent.

In mechanical integrity management, this information is essential for determining defect criticality, evaluating fitness-for-service (FFS), and defining corrective or preventive actions. Within the spectrum of industrial defectology, three major groups are especially relevant for PAUT: weld-related discontinuities, corrosion and wear, and laminations.

Weld discontinuities and defects

Welds present the highest risk of volumetric and planar discontinuities due to the thermal, metallurgical, and geometric processes inherent to welded joints. Defects typically detected using PAUT include lack of fusion, lack of penetration, porosity, undercut, slag inclusions, transverse or longitudinal cracks, and misalignment.

The use of sectorial (S-scan) and linear (E-scan) scanning enables accurate identification of defect orientation and its interaction with the ultrasonic beam, which is critical during weld inspection under normative acceptance criteria, allowing benign indications to be distinguished from critical defects (Hellier, 2001; ISO 13588:2019). In addition, PAUT offers significant advantages over radiographic testing (RT), particularly in complex geometries, greater thicknesses, or situations where radiation exposure must be avoided.

In environments governed by normative acceptance criteria (ASME, AWS, API), the accuracy of defect sizing and the volumetric representation provided by PAUT directly support more defensible decisions from technical, regulatory, and contractual perspectives.

Corrosion, wear, and wall thickness loss

In assets exposed to aggressive fluids or corrosive environments, PAUT enables the detection of degradation mechanisms such as general corrosion, localized corrosion, pitting, grooving, erosion, and wall-thickness loss. Unlike conventional UT, which provides point-based measurements, PAUT delivers a more continuous and volumetric representation of the inspected area, allowing the identification of irregularities, corrosion gradients, and discontinuities associated with both surface and subsurface deterioration.

This information is particularly valuable for components affected by flow-accelerated corrosion (FAC/erosion), corrosion under insulation (CUI), CO₂/H₂S corrosion, or differential aeration. The ability to visualize damage distribution supports remaining life estimation and integration with Fitness-For-Service (FFS) assessments or Risk-Based Inspection (RBI) programs (API 579-1/ASME FFS-1; API 580/581), optimizing decisions related to repair, replacement, or operational life extension.

Laminations and volumetric discontinuities

Laminations and volumetric discontinuities originating from rolling, forging, or drawing processes can create separation planes or metallic inclusions that compromise structural integrity and mechanical strength. PAUT is especially effective in detecting these defects, as it allows the inspection of large volumetric sections with good angular resolution and excellent coverage.

This capability is critical in plates, flanges, vessels, and components subjected to cyclic loading, where the presence of laminations may act as initiation sites for fatigue cracking or promote brittle fracture mechanisms under severe service conditions.

Industries where PAUT delivers the greatest operational value

Phased Array Ultrasonic Testing (PAUT) has seen increasing adoption across industrial sectors where operational continuity, mechanical integrity, and regulatory compliance are critical priorities. Its ability to detect, size, and characterize internal discontinuities with greater objectivity and traceability makes it a preferred method over conventional ultrasonic testing and, in many cases, over radiographic techniques.

In industries facing tight shutdown windows, strong regulatory pressure, and high safety requirements, this technique acts as a technical enabler for decision-making during fabrication, maintenance, repair, and fitness-for-service (FFS) assessments. The impact of PAUT adoption is particularly evident in three strategic domains: Oil & Gas, aerospace, and nuclear/energy.

Oil & Gas, Midstream, and Downstream

In the Oil & Gas sector, the mechanical integrity of pipelines, pressure vessels, heat exchangers, headers, manifolds, process lines, and welded joints is a determining factor for business continuity and incident prevention. This technique is widely used during construction, welding activities, in-plant inspections, certified repairs, and maintenance shutdowns.

The ability to inspect circumferential and longitudinal welds using S-scan and E-scan techniques enables the detection of oriented discontinuities, lack of fusion, porosity, and lack of penetration with greater operational accuracy. In midstream and downstream operations, degradation caused by corrosion, erosion, and thermal fatigue is assessed using PAUT to estimate remaining life and support FFS decisions under API 579 or RBI programs under API 580/581.

Reduced inspection times contribute to shorter turnarounds, while digital data recording enhances traceability and facilitates regulatory audits. In terminals, refineries, and petrochemical facilities, PAUT plays a key role in high-consequence inspections, where undetected defects may lead to catastrophic failures with environmental, economic, and reputational impact.

Aerospace sector and aeronautical applications

In the aerospace industry, PAUT is applied to the inspection of components subjected to cyclic loading, vibration, and extreme service conditions, where structural integrity is essential for flight safety. The technique allows the evaluation of joints, structures, spars, panels, landing gear, engines, and parts manufactured from titanium alloys, aluminum alloys, and composite materials. The high strength-to-weight ratio of these materials increases sensitivity to internal discontinuities resulting from forging, rolling, or bonding processes.

PAUT provides the angular and volumetric resolution required to detect laminations, inclusions, and oriented cracks, reducing the risk of fatigue crack propagation. In addition, the aerospace sector demands higher levels of repeatability, Probability of Detection (POD), and technical documentation, making PAUT platforms with advanced analysis software preferable to analog methods. Digitalization also strengthens certification processes and scheduled maintenance cycles.

Nuclear, energy, and power generation sector

In nuclear and energy applications, PAUT supports the inspection of components exposed to thermal gradients, radiation, severe loading conditions, and flow-related corrosion and erosion mechanisms. In nuclear power plants, turbines, generators, and pressure systems, early detection of discontinuities is essential to prevent sudden high-impact failures. PAUT’s capability to inspect thick sections, restricted-access welds, and complex geometries favors its use as an alternative or complement to TOFD and other volumetric techniques.

In conventional power generation, the method supports the evaluation of boilers, piping systems, HRSGs (Heat Recovery Steam Generators), tanks, and flanges exposed to thermal fatigue, creep, and corrosive attacks. Regulatory requirements and the high cost of operational downtime have driven the adoption of this method as part of predictive maintenance strategies and structural integrity assessment programs.

Recent technological advances in PAUT solutions

Phased Array Ultrasonic Testing has undergone significant evolution over the past two decades, driven by the digitalization of inspection processes, the need to improve data traceability, and increasingly stringent reliability requirements in critical industries. While early generations of PAUT equipment focused primarily on expanding the volumetric capabilities of conventional ultrasonic testing, the current trend points toward intelligent platforms that integrate hardware, advanced analysis software, connectivity, and assisted interpretation modules.

This technological convergence enables more efficient inspection workflows across fabrication, maintenance, and mechanical integrity programs, reducing uncertainty and strengthening technical defensibility during regulatory audits or fitness-for-service (FFS) evaluations. In this context, equipment manufacturers no longer compete solely on ultrasonic power, but differentiate themselves through ergonomics, portability, data quality, digital integration, and compatibility with IIoT and asset integrity ecosystems.

Digital platforms and new inspection systems

Modern PAUT platforms combine automated scanners, advanced software, and portable flaw detectors capable of operating both in the field and in laboratory environments. This evolution responds to the industrial need to inspect more components in less time, with higher repeatability and reduced operator dependency. Portable instruments facilitate inspections on piping, vessels, and complex structures, while laboratory-based systems support multimodal analysis and regulatory validation.

In the case of specialized manufacturers such as Sonatest, a clear transition can be observed toward high-performance portable detectors paired with phased array acquisition and analysis software designed for advanced inspections and digital workflows. The availability of analysis modules, configurable delay laws, sectorial and linear scanning modes, and volumetric reconstruction capabilities enhances the characterization of discontinuities in welds, forged components, and materials subjected to fatigue or corrosion.

Additionally, scanners enable mechanized scanning, improved coverage, stabilized signal response, and reduced variability inherent to manual inspections. Compatibility across scanner → detector → software platforms has become a decisive factor for adoption in Oil & Gas, aerospace, and energy sectors. This integrated platform approach promotes traceability, structured indication recording, and historical comparison in remaining life assessments.

This trend confirms that Phased Array Ultrasonic Testing is no longer solely an NDT technique, but rather part of a broader inspection data management architecture, where traceability and access to structured information directly influence operational and regulatory decision-making.

A clear example of this technological evolution is the application of Total Focusing Method Imaging (TFMI), which enhances PAUT capabilities by delivering higher-resolution ultrasonic images and improved defect characterization accuracy.

Real-Time datavisualization and interpretation

One of the most relevant advances in modern PAUT is the improvement in volumetric visualization and angular interpretation through S-scan, E-scan, and three-dimensional sectorial reconstructions. Real-time processing allows inspectors to assess amplitudes, orientations, and depths with greater accuracy.

Digital visualization also increases objectivity in defect evaluation, reduces the subjectivity associated with manual inspection, and facilitates compliance with ASME, API, AWS, and ISO codes. In sectors such as aerospace and nuclear, where documentation is critical, the ability to store data and generate digital reports strengthens certification chains and QA/QC processes.

Integration with IIoT, Digital Twins, and remote inspection

The next evolutionary step for this technique involves integrating inspections into IIoT architectures, asset integrity management systems, and digital twin platforms. This integration enables the correlation of defectology with mechanical loads, thermal cycles, and corrosion phenomena, improving remaining life prediction and Risk-Based Inspection (RBI) models. At the same time, remote inspection capabilities open new opportunities for audits, training, and real-time expert support, reducing costs and increasing operational availability in facilities with access restrictions.

Technical and operational benefits of PAUT compared to conventional UT

This technique offers significant advantages over conventional ultrasonic testing, particularly when inspections are focused on volumetric characterization of discontinuities, digital traceability, and uncertainty reduction in critical industries. While conventional UT remains a valid technique for point measurements and basic wall thickness evaluations, this technique incorporates beam focusing, sectorial scanning, digital filtering, and angular reconstruction, enabling improved defect detection, analysis, and documentation. These capabilities directly impact key operational parameters such as efficiency, accuracy, coverage, and inspection time.

- Efficiency: PAUT integrates multiple angles of incidence within a single scan, eliminating the need for repetitive inspections or multiple passes using different angled transducers. This optimizes resources during fabrication and maintenance, reduces on-site time during plant shutdowns, and allows inspection of complex geometries without dismantling structures or removing extensive protective systems.

- Accuracy: Using delay laws and controlled beam focusing, PAUT enhances sensitivity and angular resolution compared to conventional UT. This capability facilitates the identification of planar and oriented discontinuities commonly found in welds, joints, and materials subjected to cyclic loading, increasing the Probability of Detection (POD) and reliability of defect sizing.

- Volumetric Coverage: The use of S-scan and E-scan imaging enables volumetric representation of the inspected area from multiple angles, reducing operator dependency and improving defect characterization. This is particularly valuable for detecting laminations, inclusions, lack of fusion, and corrosion-related damage.

- Reduced Inspection Time: This method decreases overall inspection and documentation time, a critical factor during turnarounds or scheduled shutdowns. Digital data recording shortens reporting cycles and facilitates regulatory audits.

- Risk Mitigation: By improving traceability, objectivity, and defect detection reliability, the technique helps avoid overly conservative or incorrect integrity decisions, reducing risks associated with unnecessary repairs, premature scraping, or undetected failures.

Criteria forselecting appropriate PAUT equipment and solutions

Selecting an appropriate PAUT solution requires evaluating instrument capabilities, regulatory compatibility, and performance based on the type of discontinuity and the industrial environment. Not all PAUT systems offer the same level of resolution, focusing capability, or digital analysis tools; therefore, selection criteria should be aligned with the intended application: inspection during fabrication, in-service maintenance, or mechanical integrity assessment.

From a software perspective, it is essential to consider acquisition, processing, and data archiving tools capable of generating S-scan and E-scan images, sectorial reconstructions, and traceable digital reports. Modern platforms enable filtering, amplitude measurement, angular correlation, and automated defect sizing, reducing operator dependency and strengthening technical audits.

Resolution is another decisive parameter, as it determines the system’s ability to distinguish closely spaced discontinuities, orient crack planes, and characterize volumetric indications. Insufficient resolution may lead to ambiguous or overly conservative interpretations.

Regarding frequency selection, the choice depends on the relationship between component thickness, material properties, and defect type. Higher frequencies favor near-surface resolution, while lower frequencies allow greater penetration in thick sections or highly attenuative materials.

Finally, standards and codes must guide the selection process. ASME, API, AWS, and ISO establish requirements for examination, calibration, and acceptance criteria; choosing equipment aligned with these codes ensures repeatability, traceability, and documented compliance.

Conclusions

Phased Array Ultrasonic Testing (PAUT) has become one of the most robust and versatile technologies within the non-destructive testing (NDT) ecosystem, particularly in industrial environments where reliability, safety, and technical traceability are critical. Throughout this article, it is evident that the value of this method extends beyond detection capability alone, as it plays a central role in the accurate characterization of discontinuities, the reduction of uncertainty, and the strengthening of decision-making processes in mechanical integrity management.

The combination of advanced physical principles, regulatory compliance, volumetric visualization, and data digitalization positions PAUT as a key tool for the inspection of welds, critical components, and assets subjected to complex degradation mechanisms (ASM International, 2004; Hellier, 2001). Its cross-sector adoption in industries such as Oil & Gas, aerospace, nuclear, and power generation confirms its technological maturity and its alignment with current industrial requirements.

Furthermore, the evolution toward integrated digital platforms—with real-time analysis capabilities, connectivity, and compatibility with integrity and maintenance models—reinforces PAUT’s role as a bridge between traditional NDT methods and predictive inspection strategies. In this context, the proper selection of equipment, software, and inspection configurations, supported by qualified personnel, is essential to maximize the technical value of the examination and to ensure reliable, defensible results aligned with international standards.

References

- ASME. (s. f.). Boiler and Pressure Vessel Code (BPVC), Section V: Nondestructive Examination.

- ISO. (2019). ISO 13588:2019 — Non-destructive testing of welds — Ultrasonic testing — Use of automated phased array technology.

- ISO. (2017). ISO 19285:2017 — Non-destructive testing of welds — Ultrasonic testing — Acceptance levels for phased array ultrasonic testing (PAUT).

- ASM International. (s. f.). ASM Handbook, Volume 17: Nondestructive Evaluation and Quality Control.

- Handbook of Nondestructive Evaluation. (s. f.). Handbook of Nondestructive Evaluation.

Frequently Asked Questions (FAQs)

Which materials and geometries are suitable for PAUT inspection?

PAUT is effective for carbon steels, stainless steels, nickel alloys, aluminum, titanium, and forged or rolled components. Its performance improves in circumferential and longitudinal welds, flanges, vessels, plates, and joints subjected to fatigue, corrosion, or thermal cycling.

Can PAUT complement other NDT methods?

Yes. In fabrication and maintenance, PAUT is often combined with TOFD to improve sizing or with conventional UT for localized thickness measurements. In regulated environments, it is also used as a non-radiographic alternative to industrial RT, avoiding evacuations and safety restrictions.

How important are calibration and equipment configuration?

Critical. Proper selection of frequency, aperture, angle, focal depth, and delay laws determines test sensitivity. Calibration ensures consistency with reference standards, document traceability, and compliance with codes such as ASME, API, AWS, and ISO.

What role does software play in result interpretation?

Software is essential for acquiring, visualizing, filtering, and documenting indications. It enables volumetric reconstructions, automated measurements, layer-based analysis, and digital report generation, facilitating audits and QA/QC processes.