A research team from the Korea Institute of Machinery and Materials(KIMM), in collaboration with the Korea Institute of Science and Technology(KIST), developed the first ultrasonic sensor that achieves continuous blood pressure measurement without the need for inflatable cuffs or invasive procedures.

The non-invasive ultrasonic continuous measurement sensor

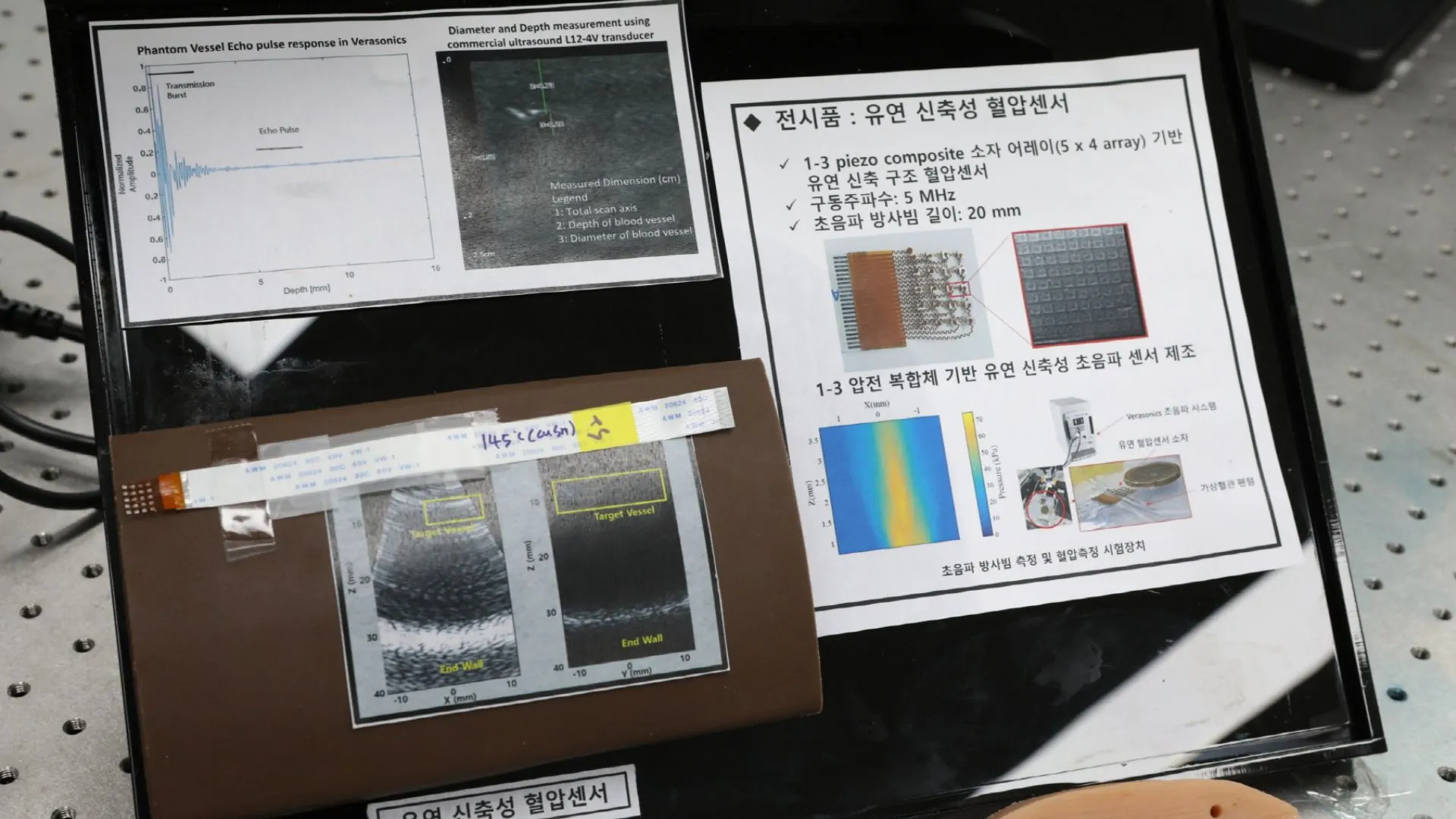

The new device works by adhering to the skin, using an ultrasonic transducer made up of a 5×4 array of elements based on PMN-PT piezoelectric materials. These high-performance crystals, integrated into a flexible substrate with low-temperature eutectic welding, enable ultrasound pulses to be sent into the blood vessels and the reflected echoes to be recorded.

By analyzing these echoes, the system detects variations in vascular diameter that correspond to systolic and diastolic pressure, generating a real-time record of blood pressure. The sensor is just over 0.5 mm thick and weighs less than one gram, allowing it to easily adapt to curved skin surfaces without compromising its performance.

While sleeveless optical methods have inaccuracies due to motion, skin color or illumination, this ultrasonic sensor overcomes these limitations by penetrating the skin and directly measuring deep arteries. In addition, by avoiding high-temperature processes, the polarization of piezoelectric materials is preserved, increasing sensitivity and reducing signal noise.

Tests on artificial models demonstrated an accuracy of ±4 mmHg for systolic and ±2.3 mmHg for diastolic pressure, meeting the AAMI clinical standard.

According to Dr. Shin Hur, principal investigator at KIMM, the integration of this sensor with artificial intelligence algorithms could enable predictive systems for cardiovascular diseases.

The development was supported by the national materials and components technology program of the South Korean Ministry of Trade, Industry and Energy, and the results were published in the leading journal Microsystem & Nanoengineering.

Source and photo: KIMM