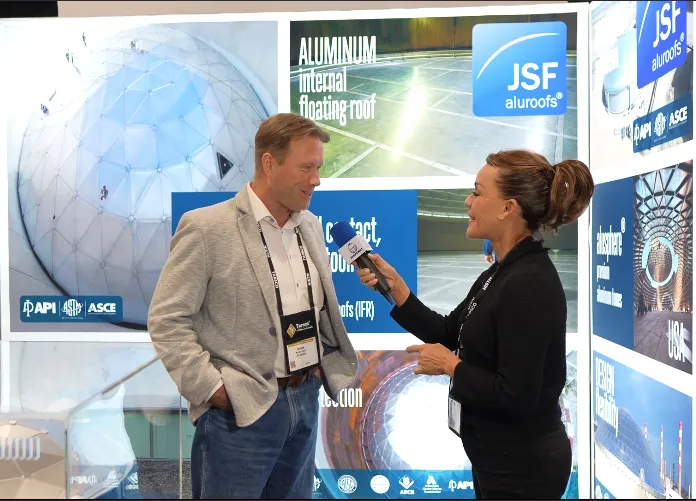

During the 2025 edition of the NISTM event in Texas, one of the most important gatherings for tank, refinery, and water plant operators, companies specializing in industrial storage solutions came together. Among them was JSF Aluroofs, a firm with more than 25 years of experience in aluminum structures for tanks. Michael Jentsch, the company's Sales Director, shared details about the performance of aluminum roofs and aluminum domes in industrial applications.

JSF Aluroofs, a brand belonging to JSF Oil & Water S.A., designs and manufactures aluminum roofs and aluminum domes for industrial facilities in different countries. The company operates with a solid technical approach, automated processes, and a specialized engineering team. Its international presence and long-term vision have positioned it as a leader in aluminum structures for tanks.

According to Jentsch, the company manufactures flat aluminum covers for drinking water and wastewater treatment plants, as well as aluminum domes for oil and water tanks. These structures can be adapted to different diameters and environmental conditions, making them a versatile option for industrial operators.

Aluminum covers are used to protect the contents of the tank and prevent the entry of external agents. In the case of aluminum domes, their main function is to protect the internal floating roof, a key component in reducing emissions in hydrocarbon tanks.

One of the highlights of the interview was the difference in weight between aluminum and carbon steel. Aluminum is three times lighter, which means less material is needed and makes transport and installation easier. This feature reduces assembly times and decreases the structural load on the tank.

Aluminum does not rust, even in coastal environments where the presence of salt accelerates the deterioration of steel. Jentsch pointed out that many tanks are located near ports, making the resistance of aluminum particularly valuable. Unlike steel, it does not require painting or galvanizing to maintain its integrity.

Aluminum roofs and aluminum domes are considered virtually maintenance-free. JSF Aluroofs has been manufacturing these structures for over thirty years, and none have required significant intervention. The proven service life exceeds three decades and is projected to reach over fifty years.

Aluminum domes are composed of standardized elements that must be assembled with precision to ensure watertightness. Incorrect installation can compromise the tank's seal, so the team's experience is essential.

Aluminum covers and domes are manufactured with compatible parts, which facilitates field assembly. This standardization reduces installation times and ensures a proper fit on different types of tanks.

In oil tanks, the internal floating roof is the element responsible for reducing vapor emissions by up to 99%. The aluminum dome acts as an external barrier that protects this system and prevents environmental factors from affecting its operation. This combination improves tank performance and reduces evaporation losses.

Although the material does not require maintenance, the quality of the assembly is key to preventing leaks, and the design of the aluminum dome promotes efficient sealing. Therefore, installation must be carried out following strict procedures.

Jentsch explained that aluminum covers and aluminum domes do not require advanced technological monitoring; the recommended inspections are visual and are performed after storms, hurricanes, or earthquakes. These checks verify that the connections to the tank remain secure and that the ventilation elements are still in place.

Unlike steel covers, which require painting or galvanizing from time to time, aluminum structures maintain their performance without additional intervention. This reduces operating costs and simplifies tank management.

Although aluminum has a higher initial cost than steel, its lightness allows for less material to be used. In addition, its resistance to corrosion eliminates maintenance costs over decades, especially in coastal areas where steel deteriorates quickly, making the difference in operating costs even greater.

Aluminum can be melted down and reused after its useful life. This feature allows the material to be used in new applications and reduces the need to produce primary aluminum, which is an advantage for industrial operators as it represents added value when evaluating long-term investments.

In the industrial storage sector, there is growing interest in materials that offer long service life and reduce operating costs, such as aluminum roofs and aluminum domes, which fit this trend, especially in facilities exposed to harsh environments.

JSF Aluroofs' participation in NISTM Texas 2025 reinforces its position as a global supplier of aluminum solutions for tanks. Its experience and the quality of its structures make it a solid choice for operators looking to improve the performance of their facilities.

For more content about NISTM 2025, please visit our LinkedIn profile.

Source: Inspenet.