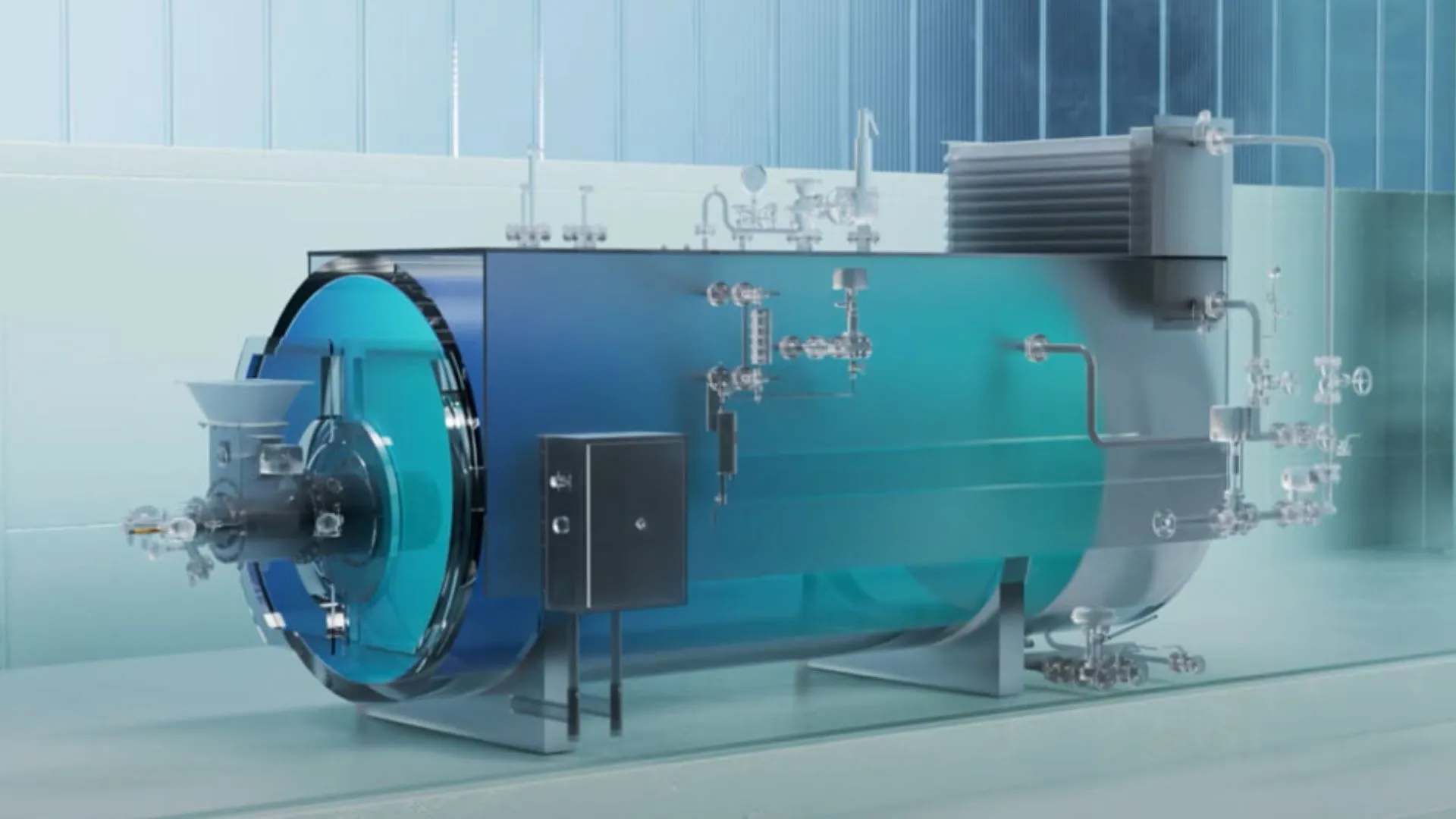

The ENGIE Group has begun construction of the first prototype of the Ch0C boiler, designed to reduce carbon emissions in industrial sectors with high thermal consumption, such as its facilities in Villers-Saint-Paul, France.

Ch0C boiler, oxy-fuel combustion and direct capture

The Ch0C boiler introduces a dual technological approach. On the one hand, it replaces air with oxygen in the combustion of natural gas, a process known as oxy-combustion. This increases energy efficiency and simplifies carbon dioxide capture. On the other hand, by concentrating the exhaust gases into CO₂ and water vapor, it allows up to 90% of the carbon emitted to be captured for later reuse or geological storage.

This technological development is the result of collaboration between 16 players from the energy and industrial sector, including ENGIE Solutions, GRDF and NaTran. It has also been financially supported by the France 2030 state program and the Ademe energy transition agency, enhancing its potential as a tool for the country’s green transition.

According to estimates, replacing some 2,000 conventional boilers with geological storage in industries such as food, chemicals and paper could prevent the emission of up to 8 million tons of CO₂ annually. This figure represents about 10 % of current industrial emissions in France.

The ENGIE group plans to launch the commercialization of the boiler from next year, with an economic proposal that competes directly with biomass boilers.

Source and photo: ENGIE