Introduction to AC mitigation

AC Interference

Growing global electrical power demand has brought about a steady increase in co-located HVAC power lines and buried pipelines within utility corridors, especially in regions with higher population density. With this has come growing challenges related to the influence of AC power on the pipelines, commonly referred to as AC interference.

The most common form of AC interference on buried pipelines is caused by the magnetic field associated with current flow on the nearby power line. This magnetic field induces a steady state AC voltage and current onto the pipeline. The degree of which is affected by many factors, including powerline load current, separation distance of each phase from the pipeline, phase transpositions, changes in pipeline distance or orientation, soil resistivity, and coating quality.

Induced AC voltage on pipelines is highly undesirable because it can

- Create hazardous touch and step voltage conditions for persons who come into contact with the pipeline and related appurtenances and

- Cause accelerated corrosion at small coating defects due to AC current discharging from the exposed metal to the surrounding soil, a phenomenon referred to as AC corrosion.

Related to human health concerns, industry standards such as NACE SP0177 and EN 50443 set limits for AC touch voltage during normal operating conditions. The specified limits for human health range from 15V in NACE SP0177 to 60V in EN 50443. These levels are steady-state values, and under fault conditions the induced voltage will be much higher. EN 50443 also provides AC touch limits under fault conditions.

Even when AC pipeline potentials are well within these limits set for human health, AC corrosion can easily occur and threaten the integrity of the pipeline. An unwanted consequence of new, high resistance coatings, AC induced current exchange between the pipeline and soil at small coating defects can achieve very high current densities – the amount of current flow per square unit of area. Most standards recommend a maximum AC current density of 30 A/m2 with higher limits allowed when cathodic protection current density is less than 1 A/m2. The risks of AC corrosion should always be considered, as it may require further reduction of the pipeline AC voltages from the levels adequate for human health protection. However, in general, only for areas with low soil resistivity (< 300 Ω-m) (2) are there typically concerns with AC corrosion.

In addition to steady state induced interference that occurs during normal operating conditions, AC faults on the powerline, which may occur with some form of insulation breakdown, result in a temporary, high amplitude induced voltage and current flow on the pipeline in the same manner as the steady state effect, but at greatly elevated levels that can create dangerous touch and step voltage for workers, and possible insulation breakdown and arcing on pipeline systems.

AC Mitigation Systems

AC mitigation systems are commonly applied on pipelines to dissipate unwanted voltage along the pipeline resulting from induced AC and AC faults. The general technique employed is to connect the pipeline at appropriate locations to a suitably low impedance earthing system to collapse the voltage to a safe value. The earthing system is commonly continuous bare zinc ribbon or copper wire run in parallel along a pipeline segment or point wells for more localized point mitigation.

The design process typically begins with software modeling by specialized consultants, incorporating various factors such as soil resistivity, separation distance, voltage and current to arrive at a voltage map at all points along the pipeline. Then, by applying low impedance earthing points at various locations along the affected area, the AC effects under steady-state and fault conditions can be modeled, and the earthing system design can be optimized to address worker safety, coating stress voltage, and AC corrosion issues. Depending on the many site variables, the spacing of earthing connections may vary between a few hundred meters to several kilometers.

AC mitigation & cathodic protection

The Impact of AC Mitigation on CP Potentials

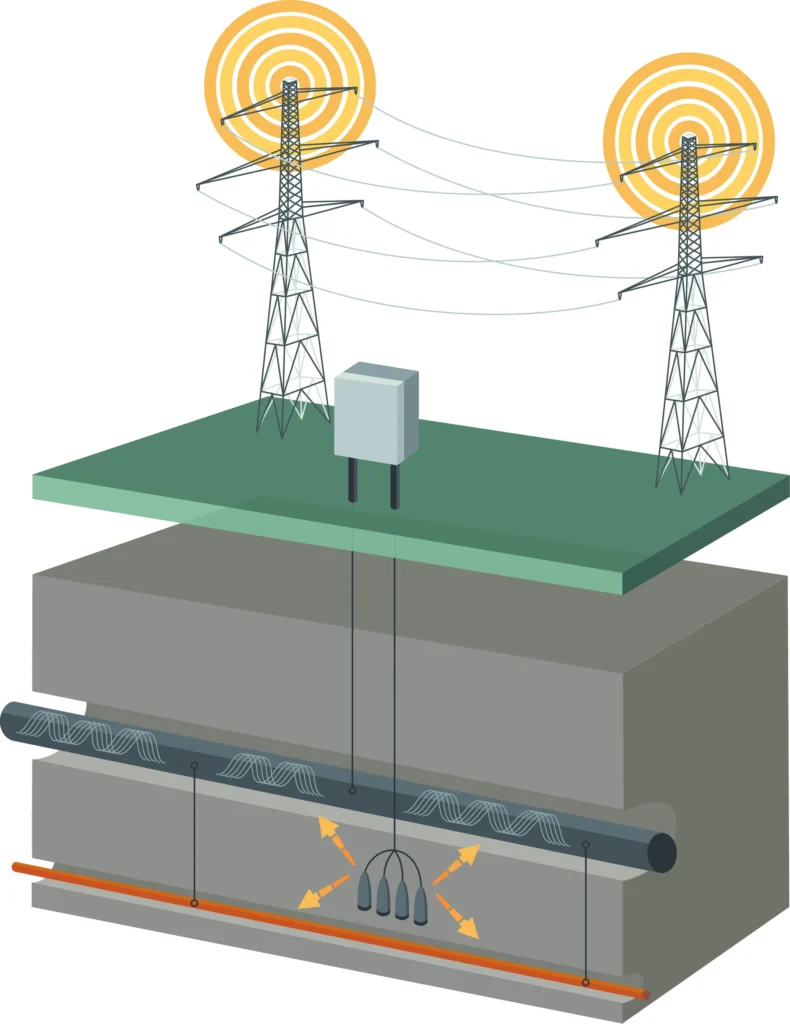

AC mitigation systems have proven to be highly effective at maintaining safe pipeline AC voltage potentials and minimizing AC corrosion. However, the mitigation earthing system that allows AC to drain off the pipeline also provides a low impedance path for CP current to flow between the anode bed and the rectifier negative terminal as illustrated in Figure 1. The earthing system, now electrically bonded to the pipeline, introduces significant additional material surface area for the CP system to protect. As a result, the rectifier often cannot support the increased current load and CP potentials can become compromised, leaving the structure inadequately protected.

When faced with insufficient CP potentials due to the required earthing bonds, CP designers might be inclined to add more rectifiers and anode beds and tolerate high CP current demand. However, this is likely a prohibitively expensive option and may ultimately not provide sufficient corrosion protection. In addition, there is the risk of driving the DC voltage on the pipeline to higher than recommended levels that may impact coating quality.

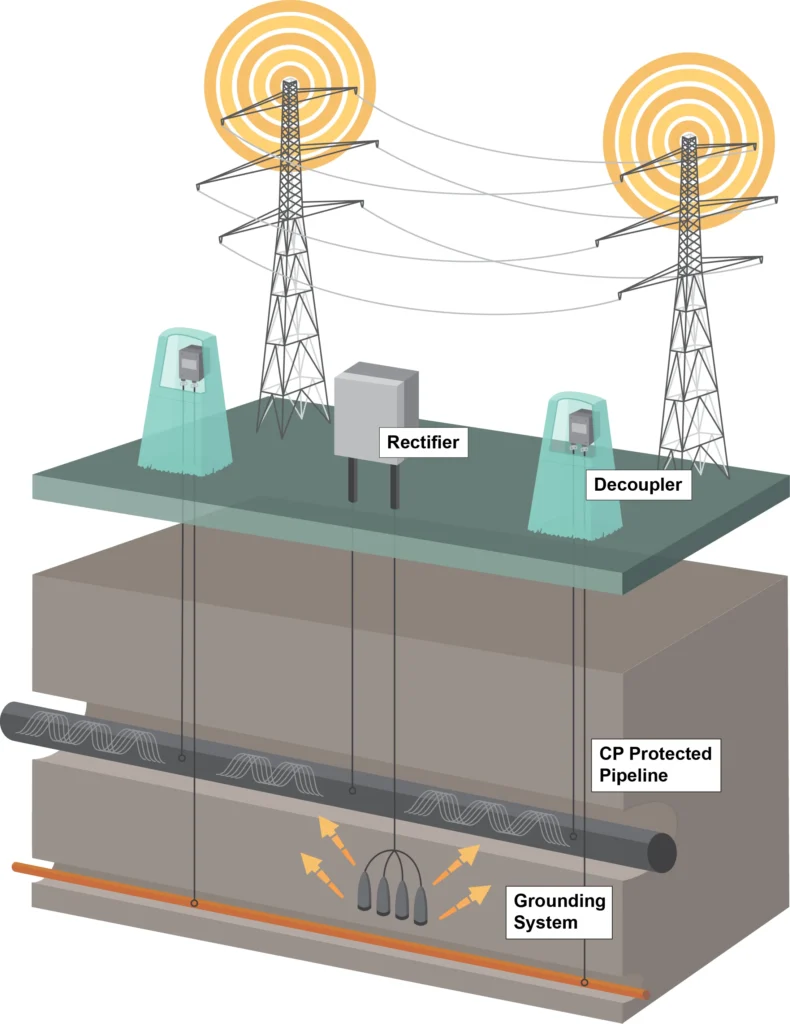

Dairyland Decouplers

A practical and widely accepted solution is to install DC decoupling devices in series with the bonding connections between the cathodically-protected structure and the earthing systems as shown in Figure 2. Decouplers are designed to block CP current while allowing steady state AC, AC faults, and lightning to pass freely. This prevents CP current from passing through the earthing systems and so dramatically reduces the amount of CP current required to protect the pipeline.

Solid state decouplers use high power solid-state electronic switching components to maintain DC isolation between structures. Under normal conditions, the circuit remains open, maintaining DC isolation between the structures. When the differential voltage across the terminals exceeds a prescribed voltage threshold, which would occur during a fault or lightning event, the circuit closes virtually instantaneously and electrically bonds the structures. Immediately following the over-voltage event, the device then automatically switches back to the open state to maintain DC isolation.

Be mindful of waveforms during interrupted surveys

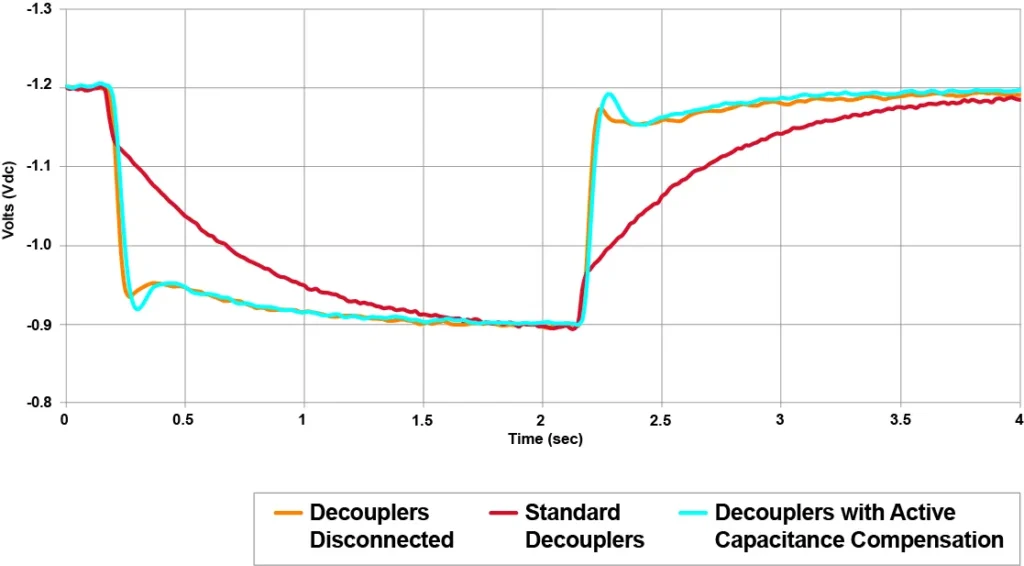

During interrupted surveys such as Close Interval Potential Surveys (CIPS), the interrupted response can vary greatly depending on the number of traditional decouplers present, as well as other parameters such as soil resistivity and pipeline coating. If not accounted for, certain combinations of these parameters can lead to instant-off readings that are more electro-negative than the true polarized potential, as shown in Figure 3.

Therefore, before recording instant-off measurements, CP Technicians should evaluate the interrupted response to determine if decoupler capacitance could be affecting the readings and, if necessary, take appropriate steps to mitigate the effect.

One common solution is to temporarily disconnect the decouplers from the pipeline during the survey. This is effective in eliminating the transient current flow from the capacitor during the OFF cycle and the resulting IR drop. This can be accomplished by physically disconnecting leads or using decoupler isolation switches. However, there are several reasons why this option should be evaluated carefully. Most importantly, while the decouplers, and thus the AC mitigation system, are disconnected, pipeline AC potentials will increase and may reach unsafe levels. This presents a significant potential safety hazard to anyone in contact with the pipeline or its appurtenances, especially since surveys can often require weeks to complete. In addition, while the decouplers are disconnected, exposure to AC corrosion is increased. In addition to the safety concerns, significant time is required to disconnect and reconnect all decouplers in the pipeline circuit being surveyed, compounding the time and cost needed to perform an interrupted survey.

Another solution is to employ decouplers having Active Capacitance Compensation, which are now commercially available in the Dairyland PCRX models. This next generation decoupler technology overcomes the slow interrupted response associated with decoupler capacitance while providing the same benefits of traditional solid-state decouplers. An example of the instant off response using this technology compared to traditional decouplers is shown in Figure 3. The decoupler always remains in the circuit during interrupted measurements to provide continuous protection from AC interference and lightning. In addition to the safety and protection benefits, long term cost savings are realized by not having to disconnect/reconnect the decouplers for every survey.

Summary

Pipeline AC interference is a growing problem wherever high voltage AC power lines are located near buried pipelines. Not only can induced AC voltage cause unsafe touch and step voltages for personnel who come into contact with the pipeline, it can also increase the likelihood for AC corrosion which can quickly perforate pipe walls where the bare pipe surface at coating defects comes into contact with low resistance soil. AC mitigation is a widely accepted and proven technique to solve such AC interference problems on pipelines.

Dairyland DC decouplers, a critical component of AC mitigation systems, dramatically improve the performance of CP systems by preventing CP current from flowing through, and thus protecting, the earthing system. It is important to be aware of the effect of decoupler capacitance on measured instant-off potentials. To ensure accurate and efficient CIPS surveys, waveforms should be reviewed and, where needed, decouplers should either be temporarily disconnected during the survey or decouplers with Active Capacitance Compensation should be used.