The inspection of offshore risers using in-line inspection technology is a complex operation with inherent risks. However, it represents a particular challenge when risers were not built with standard pigging facilities (such as launchers and receivers) or when operating conditions do not allow pigging operations.

In 2024, a major operator in the Gulf of Mexico faced these challenges when inspecting its hazards, so it turned to ROSEN for an alternative solution for in-line inspection. The company operates multiple offshore assets in the Gulf of Mexico, including two risers considered at risk of external corrosion in the splash zone. As a result, the operator required inspections of the risers to identify potential corrosion damage from the splash zone to the seabed in order to take action to ensure the safety and service life of these critical offshore assets.

The project presents several challenges that tested ROSEN’s technical capabilities and operational resilience. Conducting operations offshore adds layers of complexity due to the remote location, harsh environmental conditions and the need for specialized equipment and logistics. In addition, free-swimming solutions were not an option, as the client preferred to avoid the use of external equipment such as pumps and vessels for fluid circulation. This constraint called for a more innovative and self-sufficient approach. With only one access point available, ROSEN had to ensure efficient deployment and recovery of equipment without compromising inspection integrity.

The risers had exceptionally high wall thickness, which made ultrasonic technology (UT) the ideal choice to ensure accurate detection and assessment of possible corrosion. Finally, the absence of launching and receiving facilities on the platform forced ROSEN to develop innovative methods for inserting and removing the inspection tool.

Faced with these complexities, ROSEN employed its wide range of technologies to formulate an ideal approach, selecting the most appropriate propulsion elements and the best measurement technology for the asset, while ensuring sufficient failsafe elements for the inspection tool itself.

A self-propelled, tethered inspection tool was chosen that could move independently through the risers without relying on liquid or gaseous propellants. This tool could be inserted from the access point on the platform, eliminating the need for subsea modifications. It would then travel to the end of the seabed, where it could be stopped and retrieved by a winch system located on the platform, without the need for subsea support equipment.

This solution made it possible to perform the inspection without removing the product from the risers and without underwater work, thus minimizing potential environmental risks.

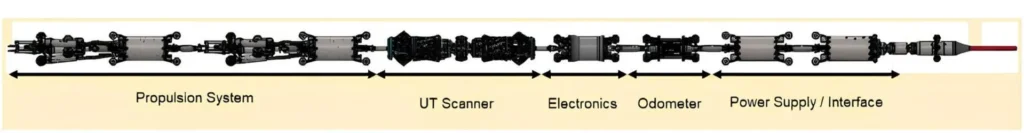

The tethered crawler inspection tool (Figure 1) consisted of a UT scanner module, a crawler drive unit and an odometer segment, followed by the transformer (trafo) and interface units.

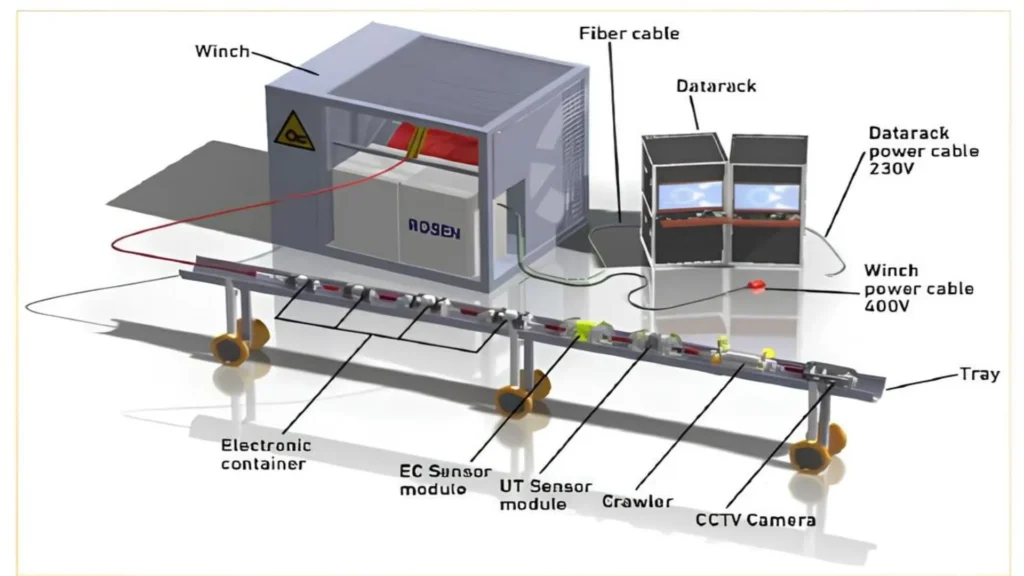

The survey tool was connected to an umbilical winch and a computer system to communicate and control the tool as it navigated the risers (Figure 2). During the operation, the survey team closely monitored and controlled the tool’s movement from the surface. The UT data collected could be viewed in real time, allowing the onsite analyst to adjust components such as sensor gain to improve data quality. In addition, the analyst could make additional passes over areas of interest to ensure a thorough inspection.

Prior to its offshore deployment, ROSEN conducted a rigorous blind test demonstration at a specialized engineering facility to validate the tool’s sensing and sizing capabilities. This test was instrumental in demonstrating the effectiveness of ROSEN’s solution under controlled conditions prior to application in the challenging offshore environment.

In this demonstration, the engineering facility provided a controlled environment that simulated heavy wall thickness and other conditions specific to the platform risers. The crawler accurately detected and sized various anomalies, demonstrating its ability to deliver accurate and reliable data. The success of this blind test gave the client confidence that the inspection tool would meet requirements during actual offshore operation.

The inspection was successfully completed in May 2024, providing the client with critical data on the condition of its risers. This project not only demonstrates ROSEN’s ability to handle complex offshore inspections, but also reinforces the company’s position as a leader in self-propelled inspections. As a precedent for future offshore inspections, the project evidences ROSEN’s ability to develop and implement tailored solutions that overcome even the most complex challenges, while highlighting the fundamental role of technology in modern offshore inspections.

Advanced sensor technology, such as ultrasonic testing (UT) sensors used in ROSEN’s custom-designed crawler, enable accurate detection and measurement of pipeline anomalies. These sensors can penetrate thick pipeline walls and provide high-resolution data essential for accurate assessment of pipeline conditions. In addition, the development of self-propelled crawlers represents a breakthrough in inspection technology. Unlike traditional methods that rely on external equipment for propulsion and navigation, self-propelled crawlers can move independently within the pipeline. This capability is especially valuable in challenging environments where deploying external equipment is impractical or risky.

Working closely with the client, ROSEN was able to develop a solution that met their specific needs and addressed their unique inspection challenges. This collaborative approach ensured that the solution was not only technically sound, but also practical and feasible within the constraints of the offshore environment. Innovation was at the heart of this project. From designing the custom crawler to conducting extensive planning activities and simulations, the team continually pushed the boundaries of what was possible in offshore inspections. This commitment to innovation allowed ROSEN to overcome numerous challenges and deliver a successful outcome for the client.

This article was developed by the specialist Fernando Perez and published as part of the sixth edition of Inspenet Brief September 2025, dedicated to technical content in the energy and industrial sector.