Severe corrosion damage has been observed on tanks in a wide range of operating temperatures and geographies, even though in many of these cases, the maintained conditions led the asset owner to believe that risk of corrosion under insulation (CUI) damage was relatively low. Examples of these conditions include a cold and dry climate, operating temperatures that were below freezing, operating temperatures that were above ambient and maintained a positive vapor drive, or operating temperatures that did not compromise the hydrophobic properties of the insulation material. In this article, we will look at some of the lesser-known aspects of CUI mitigation in insulation system design, and the realities faced on-site that can compromise specified solutions.

Moisture is a risk for all process temperatures

CUI is a result of contact between a metal and aerated liquid water. However, it is important to consider that insulation systems for all operating temperatures are at risk of moisture ingress, in both liquid and vapor forms.

While tanks that operate below the freezing point of water will typically not experience corrosion during operation, since moisture should be solid ice at the metal surface, moisture can still condense and be stored inside a permeable insulation material. Once the system is shutdown, this moisture can be released and react with the metal.

Cyclical operations can increase the rate of corrosion. During operation at above-ambient temperatures, moisture can evaporate but leave behind ever-increasing concentrations of any contaminants that were carried in with the water. Once the system switches to cold process temperatures, or a shutdown occurs, these concentrated contaminates can move to the metal surface, ready to cause significant corrosion damage. This mechanism frequently applies to above-ambient processes as well, since most operations will eventually experience a shutdown. In this regard, even above-ambient processes are effectively in cyclical operation, it just occurs over longer time periods.

Asset owners and specifiers are commonly advised that for above-ambient operations, the positive vapor drive through a permeable insulation material will be sufficient protection against CUI. However, this advice does not consider that in many cases the insulation material never fully dries as moisture cannot escape the impermeable insulation system. Perhaps more importantly, such advice fails to consider one of the real-life aspects of most tanks — protrusions. During cold weather, protrusions can introduce a cool surface inside the insulation system, which facilitates condensation, even for above-ambient operations. This is reflected in many owner experiences on-site, where protrusions are identified as the area where significant CUI damage occurred on an above ambient tank.

Specifying a vapor-tight insulation system

To defend against vapor moisture ingress, a vapor-tight insulation system must be installed. Within an insulation system, there will be several components where a vapor impermeable layer can be specified. Typically, these can include a vapor retarder exterior to the insulation material, the jacketing, or the insulation material itself.

Vapor retarder materials are frequently compromised by the installer, who might use different shortcuts to reduce installation time. Examples can include relief cuts, improper terminations, or the use of separate pieces rather than forming a single piece into a sharp angle. Many times, such deviations are in hard-to- see locations and can be missed during inspections. While these shortcuts may reduce installation time, they will obviously compromise the vapor tightness of the insulation system.

The effectiveness of the jacketing against moisture ingress will usually depend on the ability of the caulking to maintain a seal between the metal pieces. However, UV degradation of the caulking will result in its eventual failure. Also, even when new, caulking cannot compensate for the poor fit in jacketing that is frequently observed on-site. Keep in mind that an opening of just 1/8” can be considered a “large” opening for the caulking to seal.

The jacketing system will be exposed to a host of natural and man-made events that will inevitably result in openings in the insulation system. Whether from storms, wildlife, mechanical damage, or an unrepaired opening from an integrity inspection (which is ironically the cause of some of the worst openings in an insulation system), a jacketing system will eventually succumb to moisture ingress unless regular inspection and maintenance is performed.

Addressing the difficult geometries present on most tanks and vessels

Installing a vapor-tight insulation system is easier said than done. Even if installed properly, and before any damage has occurred, vapor retarders and jacketing will struggle to maintain a vapor-tight seal on some of the challenging geometries present on most tanks, such as angle iron supports or brackets. These two components of the insulation system are composed of thin materials, and as such they will typically only make a thin line contact with protrusions.

The unique advantages of utilizing the insulation material as an impermeable layer

The insulation material stands apart from these other components in that it can match the thickness of the insulation system. As such, it can make a full depth seal with protrusions.

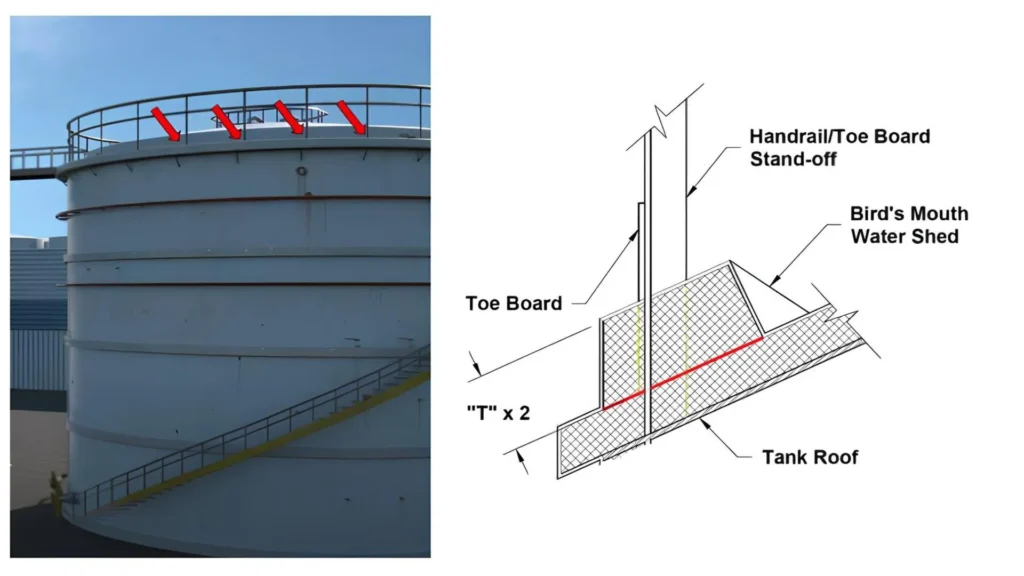

FOAMGLAS® cellular glass insulation is completely impermeable1. The existence of an impermeable material which is not a thin layer is a truly powerful tool in the insulation specifier’s toolbox. Suddenly, sealing difficult angle iron geometries becomes quite easy. See Figure 1, which shows handrail supports, a common angle iron protrusion on many tanks.

The location of this type of protrusion at the top of a tank makes it quite susceptible to moisture ingress. A “3D” vapor barrier material, like a block of FOAMGLAS® cellular glass insulation, easily matches the geometry of angle iron, and achieves full-depth contact for a reliable seal. Since the sealant will be shielded from UV exposure underneath the jacketing, this method can maintain a reliable seal for decades, successfully mitigating CUI.

This article was developed by the specialist Fadi Bachir and published as part of the sixth edition of the Inspenet Brief September 2025, dedicated to technical content in the energy and industrial sector.