Engineering firm Kyoto Fusioneering has begun the testing stage for hydrogen recovery from liquid metalusing its innovative patented vacuum sieve tray (VST) technology. This program, taking place at the UNITY-1 integrated test facility, seeks to establish a continuous and stable supply of feedstock for future fusion reactors.

The challenge of commercial nuclear fusion

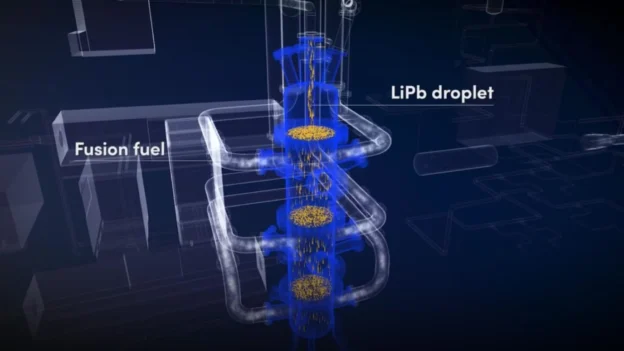

The transition to commercial commercial fusion energy depends on one crucial factor: the fuel cycle. Deuterium and especially tritium are the hydrogen isotopes that serve as key fuels. Because of the extreme natural scarcity of tritium, it must be “bred” or generated inside the reactor. The process involves neutrons interacting with a liquid lithium-lead (LiPb) alloy contained in the cladding module.

That is, the most important technical challenge is the efficient separation of the newly produced tritium from the hot liquid metal. Kyoto Fusioneering is developing a complete Fusion Fuel Cycle System, which will be demonstrated in the upcoming project UNITY-2 project, covering the generation, storage and effective recovery of this rare isotope.

A superior extraction mechanism

Consequently, the heart of Kyoto Fusioneering’s solution is the VST device. This system makes it possible to simulate the extreme heat conditions required for the power generation power generation. For this purpose, the LiPb alloy is poured into a vacuum environment. Inside the device, internal sieve trays disperse the fluid into multiple small droplets.

This mechanism also significantly increases the surface area of the liquid metal, facilitating the release and efficient extraction of tritium in its gas phase. At the current stage at UNITY-1, the company is using deuterium and ordinary hydrogen as surrogates to validate the physical principle of recovery. The data obtained in this test will be instrumental in finalizing the design of the VST system that will operate with real tritium in the next phase.

UNITY projects and industrial consolidation

Additionally, the UNITY-2 project, currently underway, represents the next large-scale validation. This effort, developed in Ontario, Canada, is a joint venture between Kyoto Fusioneering and Canadian Nuclear Laboratories (CNL). UNITY-2 will be the ultimate platform that will validate the VST technology in a key isotope operating environment, demonstrating the closed fuel cycle.

Finally, the importance of this demonstration is endorsed by co-founder and CEO, Satoshi Konishi, who states that these tests give its industrial partners the confidence needed to ensure a reliable fuel supply in future commercial fusion deployments. The company’s specialization in critical systems such as the fuel cycle and tritium-generating blankets reaffirms its leadership position in the realization of this sustainable energy source.

Source and photo: Kyoto Fusioneering