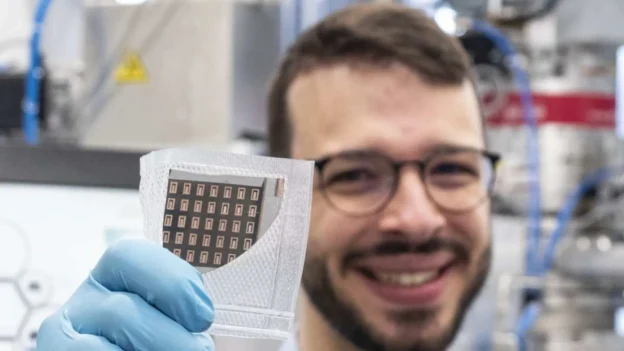

Swiss company BTRY has developed a technology based on solid-state batteries only 0.1 mm thick, capable of charging in less than a minute and operating up to 150 °C without degrading.

Solid state battery technologies

Microbatteries would represent a leap in efficiency and safety compared to liquid electrolyte technologies. In addition, their solid structure avoids problems such as swelling, leaks or combustion risks. Their thermal resistance also allows them to be integrated in sectors such as precision agriculture, digital health, automotive or defense.

This development was inspired by semiconductor technology, its roll-to-roll system uses no solvents and generates no liquid waste. This approach reduces costs, improves scalability and enables customized formats for different industrial applications.

Continuous coil manufacturing enables the development of power components in series, eliminating dependence on conventional chemical processes. This contributes to cleaner and more efficient electronics.

Within a year of its founding, BTRY has raised $5.7 million in a seed round to scale its technology from the lab to industrial manufacturing. Investors include funds such as Redstone VC, Bloomhaus Ventures, Linear Capital and Kickfund, as well as support from HTGF and the Cantonal Bank of Zurich.

The integration of thinness, thermal stability and fast charging capability positions these batteries as ideal candidates for demanding environments. From agricultural sensors operating in extreme climates, to remote IoT devices that require extended power autonomy and low maintenance.

Thanks to their compact architecture, they reduce weight and eliminate ancillary components, improving the overall design of electronic devices. They also integrate with energy harvesting systems and flexible electronics.

The team is led by physicist Dr. Moritz Futscher and engineer Abdessalem Aribia, with experience at institutions such as ETH Zurich and Empa. With a group of 14 people, they drive a vision of responsible electronics based on sustainable microfabrication.

Source and photo: BTRY