At the ASNT 2025 conference, Nova Instruments, represented by its Global NDT Sales Manager, Zeki Gokce, presented a technological solution that is changing the way the industry performs ultrasonic inspection on pipe welds. The combination of an orbital scanner and an ultrasonic acquisition unit offers a faster, safer and more efficient alternative to traditional methods such as industrial radiography.

The solution was exhibited at the booth of Phoenix ISL, one of the brands that make up the Nova Instruments group together with Technology Design, manufacturer of the FocusScan RX II inspection unit. This collaboration reflects a comprehensive approach to addressing today's challenges of nondestructive inspection (NDT) in technically demanding environments.

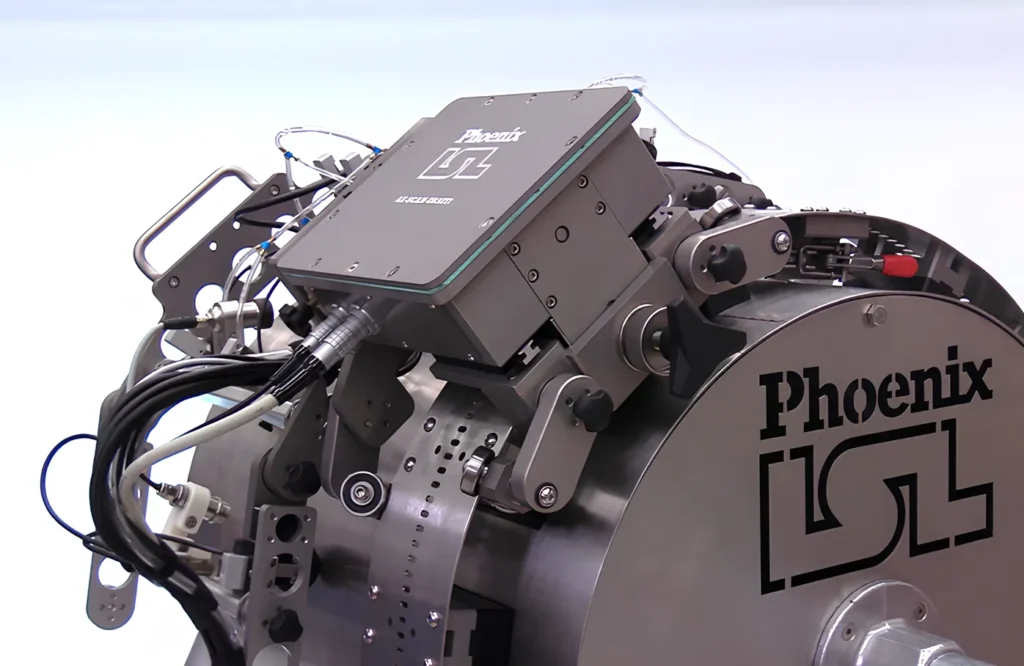

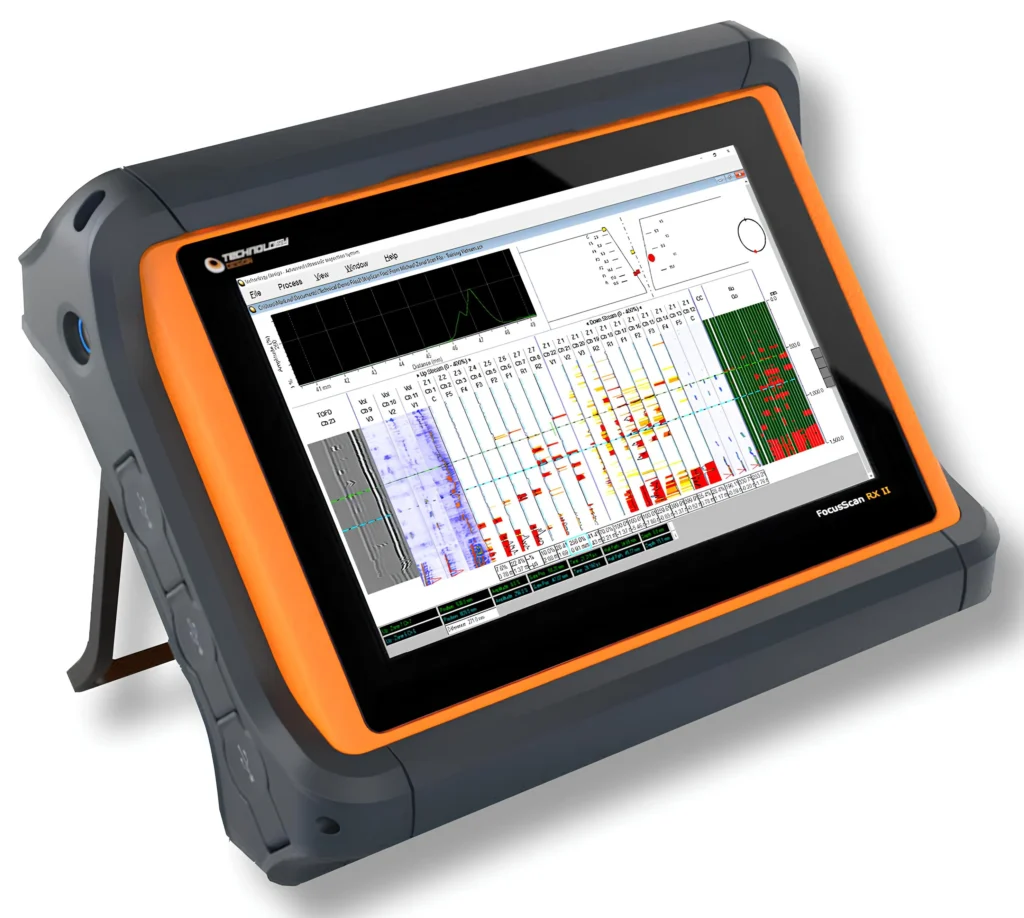

The system consists of two main elements: the Orbital AUT Weld Scanner, a flexible rail-mounted scanner manufactured by Phoenix ISL, and Technology Design's FSRX II (FocusScan RX II) unit, designed to perform ultrasonic inspection of circumferential welds. This configuration allows automating the process of evaluating welded joints, especially in pipelines used in the energy, petrochemical and fluid transportation industries.

Both devices can operate together as a turnkey solution, or be retrofitted into existing field configurations, providing flexibility for companies looking to partially upgrade their inspection system without replacing their entire infrastructure.

The procedure starts once the weld has been made, usually automatically. The orbital scanner is positioned around the pipe and moves precisely along the weld seam. During this travel, it transports and positions the ultrasonic transducers connected to the FSRX II unit, which records the data in real time.

This type of inspection is performed in accordance with the guidelines of the API 1104 standard widely used in pipeline infrastructure projects. The information collected allows identifying defects such as lack of fusion, porosity or metallic inclusions, depending on the welding technique applied.

The system interface allows the results to be displayed on a local screen or analyzed later in a more robust software environment. The goal is to determine whether the weld is acceptable or requires repair, quickly and accurately.

One of the aspects most valued by Zeki Gokce during the interview was the time reduction in system commissioning, which can be installed in an afternoon, while other methods may require days. This represents a considerable saving in projects where every hour of delay has an economic impact.

Unlike industrial radiography, which involves risks associated with X-ray exposure, ultrasonic inspection allows operation in the presence of personnel, eliminating the need for evacuation or isolation measures during evaluation. In addition, the system offers increased speed of operation and full coverage of the weld without sacrificing detail or depth.

The modular design of this solution responds to a growing demand for systems that are easy to transport, install and operate. In contexts such as pipeline construction or critical facility maintenance, the ability to move equipment from one inspection point to another without complex procedures represents a substantial operational improvement.

The option of purchasing the scanner separately or together with the acquisition unit gives companies room for maneuver to integrate new technologies without completely abandoning their previous investments.

Although the system presented does not currently incorporate artificial intelligence algorithms, the interviewee acknowledged that automation and intelligent analysis are fields that the company is following closely. The goal is to continue optimizing evaluation processes, reducing human intervention in repetitive tasks and improving the traceability of results.

With the support of specialized brands such as Phoenix ISL and Technology Design, Nova Instruments strengthens its position as a provider of advanced inspection solutions, aligned with today's market demands for quality, safety and efficiency.

For more content about ASNT 2025, please visit our LinkedIn profile.

Source: Inspenet.