Large-format additive manufacturing has seen a boom through initiatives that propose to overcome common problems such as cracking and warping. The MAT3D-XL project is an organized experiment of AIMPLAS that seeks to find the answer, through the use of sustainable composites and thermal control technologies for the creation of multiple developments.

The new approach to large-format additive manufacturing

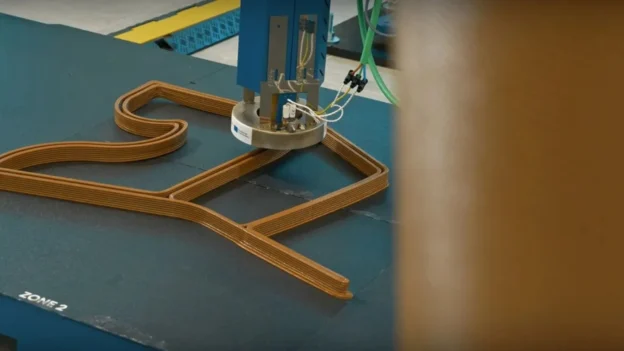

MAT3D-XL technology develops thermoplastic materials of recycled or bio-based origin, reinforced with carbon, glass and natural fibers. This integration improves the stiffness and strength of the printed parts, and also reduces thermal shrinkage, an essential factor in the stability of the final product. With this, AIMPLAS responds to the need for more reliable processes in structurally demanding applications.

The implementation of infrared (IR) heating systems integrated in the printing process allows controlling the temperature layer by layer, favoring better adhesion between sections and minimizing structural defects. In other words, more consistent results are guaranteed in prints of more than one cubic meter without additional assemblies.

The organization has validated this technology with functional prototypes in collaboration with Plàstic Preciós La Safor. These include street furniture and structures for interior design, all made from recycled materials.

The initiative, funded by IVACE+i and the ERDF, is aligned with the Sustainable Development Goals and seeks to reduce dependence on non-renewable resources. By integrating innovation in materials, design and processes, AIMPLAS enhances its role as a technological reference in advanced additive manufacturing.

Source and photo: AIMPLAS