As part of the ASNT 2025 event, Frédéric Laprise, Vice President of UT Technologies at Eddyfi Technologies, shared details about the company's latest advances in non-destructive inspection (NDT), with an emphasis on its flagship product: WeldXprt.

Eddyfi Technologies, headquartered in Quebec and present in more than 110 countries, specializes in critical ultrasonic inspection solutions, eddy current, automated vision and robotics. The company is part of the Previan group, and serves sectors such as energy, aerospace, mining, power generation and transportation.

During the interview, Laprise pointed out that one of the great challenges in industrial pipeline construction is to achieve accurate inspection in ever shorter time frames. In contexts of high operational demand, any solution that speeds up the process without sacrificing the quality of the analysis becomes essential.

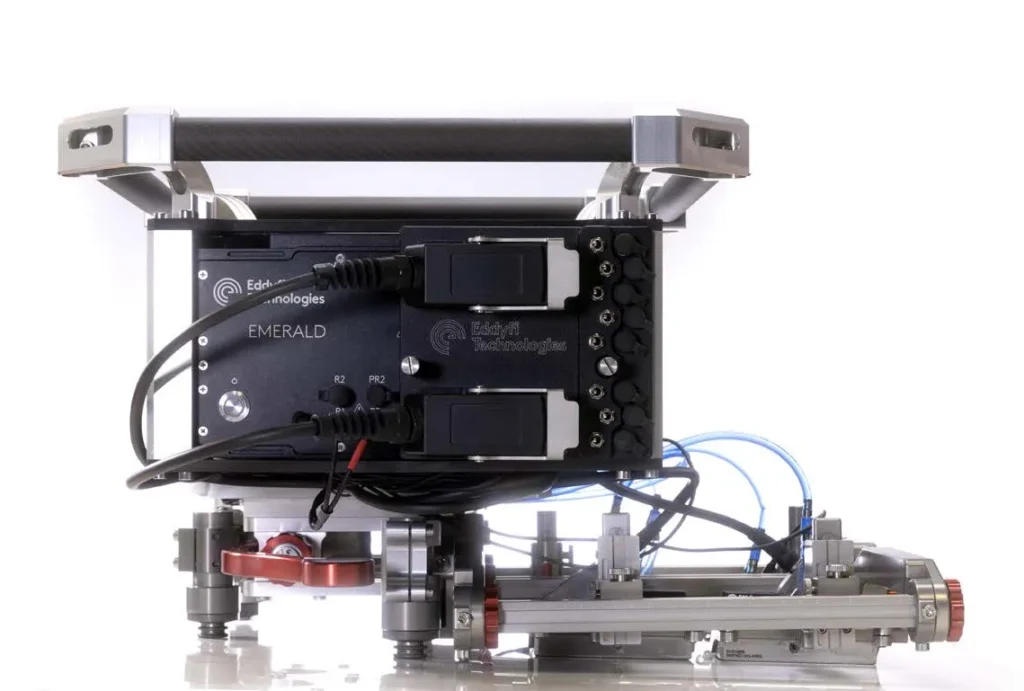

Eddyfi's answer to this need is called WeldXprt; this tool allows a weld inspection to be performed in just three to five minutes. To achieve this, the platform combines advanced ultrasonic technology with software that automates setup, calibration and process analysis.

"We listened to what the market needed and redesigned the software for a much smoother user experience. Today you can set everything up in very few steps and get reliable results almost immediately."

Frédéric Laprise.

In addition, the system includes automated analysis according to the inspection codes required by industry regulations, improving speed and traceability, while maintaining consistent reporting.

WeldXprt and other company solutions can be integrated via APIs and SDKs, allowing users to adapt the tools to their specific needs or incorporate them into existing systems. This flexibility responds to a trend in industrial digitization: the customization of workflows according to the type of asset and operating environment.

"We want our customers to be able to take parts of our solutions and adapt them. It's a modular approach that respects the diversity of applications in the field."

Frédéric Laprise.

While WeldXprt does not employ AI directly, other Eddyfi do, particularly in tube inspections in heat exchangers. In these cases, the use of artificial intelligence models makes it possible to detect deterioration patterns with greater accuracy and reliability.

In addition, the company is collaborating with partners to implement AI in ultrasonic processes, which represents an active and constantly evolving line of work.

The participation of Eddyfi at ASNT 2025 demonstrates its commitment to operational efficiency, technology integration and the continuous evolution of critical inspection tools, an approach that stems from its philosophy of user-centered innovation; indeed, as Laprise made clear, the development of WeldXprt started from an active listening to industry requirements, which has allowed them to consolidate their position as a benchmark in the NDT sector.

For more content about ASNT 2025, please visit our LinkedIn profile.

Source: Inspenet.