Table of Contents

- Are heat exchangers pressure vessels?

- Types of heat exchangers

- Shell and tube heat exchanger components

- Common failure mechanisms in heat exchangers

- Advanced Predictive Inspection Techniques (ANDT)

- Applicable norms and standards (API, ISO, NACE)

- Integrated technology for optimal integrity management

- Conclusions

- References

- Frequently Asked Questions (FAQs)

- Why is this equipment a pressure vessel?

- What types of heat exchangers are most commonly used?

- What is advanced NDT and what is its application?

- What are the most frequent failure modes in this equipment?

- What is the purpose of API 660 in this context?

- What does infrared thermography (IRT) provide?

- How do ANDTs contribute to predictive maintenance management?

- What is the Eddy Current Array Assay (ECA)?

- What other standard applies to the inspection of pressure equipment?

- What benefits did the Mistras Group case show for ANDT?

Heat exchangers are essential in industrial processes, facilitating the transfer of thermal energy and optimizing operating efficiency. Their operation under pressure confers them the classification of pressure vessels, requiring strict compliance with standards such as API 660 and ASME BPVC.

This classification demands rigorous inspections and the use of advanced NDT techniques, ensuring mechanical integrity, safety and thermal performance. This article explains the most common failure mechanisms, the most effective predictive ANDT inspection techniques under the pressure vessel premise, how these methods operate with their applications and the benefits of smart maintenance.

Are heat exchangers pressure vessels?

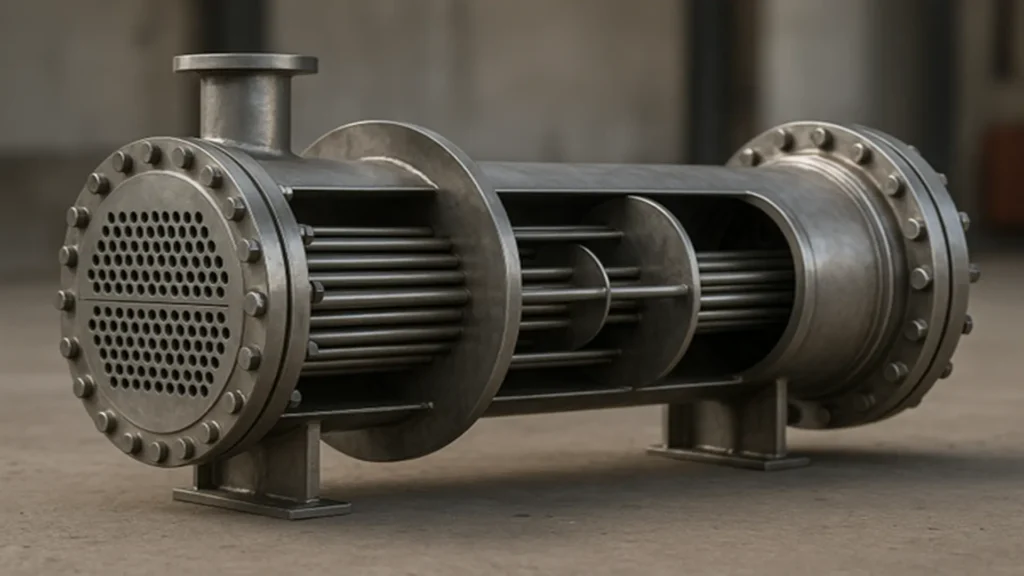

The shell and tube heat exchanger, widely used in industrial plants, has two compartments: the shell and the tube bundles. Both contain fluids subjected to internal pressures that can greatly exceed atmospheric pressure, depending on the application (e.g. oil & gas processes, petrochemical, power generation).

International standards such as API 660 and ASME BPVC Section VIII state that any equipment operating at pressures above 1 bar must be considered a pressure vessel. In the case of heat exchanger types, both the shell and tubes are designed to withstand these conditions, including differential pressures, thermal stresses and additional mechanical loads.

This classification implies compliance with rigorous controls in design, manufacturing, hydrostatic testing and inspection of pressure vessels, thus allowing safe and reliable operation in critical sectors.

Types of heat exchangers

In the industrial field there are different types of equipment, but not all of them are designed to operate as pressure vessels. When the equipment is required to contain fluids at pressures above atmospheric and meet strict API and ASME BPVC regulations, the most commonly used type is the shell and tube heat exchanger.

This design is available in various configurations to suit different critical industrial processes:

- Single-pass exchanger: Ideal for applications where pressure and temperature differences are moderate.

- Multi-pass exchanger: Increases thermal efficiency by forcing several fluid paths in the tubes, supporting greater thermal differences.

- With floating head: Designed to absorb thermal stresses and facilitate internal cleaning, used in severe services with high pressures.

- With U-tubes: Allows greater thermal flexibility and reduces the number of critical seals, but may hinder complete internal inspection.

There are other designs or types of shell and tube equipment, such as plate or spiral shell, which are typically used in lower pressure applications and moderate flow rates. In this article we will discuss only shell and tube heat exchanger types.

Shell and tube heat exchanger components

A shell and tube heat exchanger consists of fundamental parts. Their integrity is significant in the process of efficient heat transfer. Each component serves a specific function under pressure conditions.

The main elements include the casing, tube bundle, tube plates and baffles. Each is critical for fluid containment and flow direction.

- Tube bundle: The tubes themselves, which are the main heat transfer surface.

- Tube plate: Perforated plate to which the tubes are attached.

- Shell (or casing): The outer casing that contains the fluid on the shell side.

- Baffles: Plates that direct the fluid flow on the shell side and support the tubes.

- Headers (or caps): Components at the ends that direct fluid flow on the tube side.

- Nozzles: Connections for fluid inlet and outlet.

- Welds: Joints that connect the different components.

Common failure mechanisms in heat exchangers

Despite proper design and manufacture, heat exchangers are subjected to severe conditions that can cause failures, hence the importance of technical inspections. The most important inspections include the following:

- Tube bundle failures: Wear, erosion and corrosion: Erosion by abrasive fluids and mechanical wear reduce wall thickness. Corrosion (generalized, pitting or stress corrosion) is common, especially by wet H2S. Material selection according to NACE MR0175 is required.

- Fouling: Loss of Thermal Efficiency: Accumulation of deposits that reduces thermal efficiency and forces frequent shutdowns.

- Fatigue and vibration: Progressive structural deterioration: Flow-induced vibrations stress the pipes, causing progressive cracks.

- Casing failures: Compromised structural integrity: Internal and external corrosion, fatigue cracks, and nozzle erosion.

- Baffles: Wear and effect on flow and tubes: erosion wear and deformations affecting flow and generating excessive vibrations.

- Tube plates and headers: Critical leakage points: Critical areas with high risk of localized corrosion, cracks and leaks in tube-plate joints.

To mitigate the risks arising from these failures and ensure continuous operation, advanced predictive inspection techniques (ANDT) are employed.

Advanced Predictive Inspection Techniques (ANDT)

Advanced Non-Destructive Testing (NDT) is a set of innovative and highly specialized methods that go beyond conventional non-destructive testing (NDT) techniques and are aligned with the Pressure Vessel Inspection standard.

They detect anomalies before they become serious failures, reducing costs and improving operational reliability.

Ultrasonic Testing by (PAUT) and (TOFD)

- Components: These are ideal for inspecting welds on exchanger housings, headers and nozzles.

- Application: PAUT and TOFD to detect and size cracks, inclusions, lack of fusion and other volumetric or planar defects that could compromise the structural integrity of welds. PAUT allows a complete mapping of the weld, while TOFD offers superior accuracy in sizing defects, important for assessing their severity.

Digital Radiography (DR) and Computerized Tomography (CT)

- Components: Especially useful for examining baffle plates, tubes (at their ends or where there are geometry changes) and complex welds on exchangers where geometry makes other techniques difficult.

- Application: DR can identify internal defects such as corrosion, erosion, improperly installed pipe plugs or weld defects. CT, by offering 3D imaging, is invaluable for analyzing internal tube geometry, detecting blockages, assessing the integrity of tube-plate joints and accurately characterizing the extent of corrosion or fouling.

Eddy Current Array Test (ECA)

- Components: This is the most commonly used technique for inspection of tubes (both U-tubes and straight tubes), tube sheet and, in some cases, baffle plates if they are made of conductive materials.

- Application: ECA allows fast and accurate scanning of tubes for a wide range of defects, including pitting, wall thinning (corrosion/erosion), stress corrosion cracking (SCC), and vibration impact damage. The coil array improves coverage and detection of oriented defects in a variety of ways, making it superior to conventional Eddy currents for this purpose.

Acoustic Emission Testing (AET)

- Components: Complete casings, tubes and tubesheets while the exchanger is in service or under pressure testing.

- Application: AET is a global monitoring technique. It can detect defect activity in real time, such as crack propagation, active leakage or deformation of materials under load. This is especially useful during hydrostatic or pneumatic testing, to monitor the integrity of large exchangers without dismantling them.

Guided Wave Ultrasonic Testing (GWUT)

- Components: Long pipes connected to the heat exchanger or, in some cases, the tubes of the heat exchanger itself if they are accessible in long lengths.

- Application: GWUT is excellent for quick inspection of large pipe sections for metal loss (corrosion, erosion) or laminations. Although less common directly on tube bundles due to geometric complexity, it is vital for exchanger inlet and outlet piping where corrosion can be a problem.

Electromagnetic Ultrasonic Field Assay (EMAT)

- Components: Primarily for inspection of tubes and potentially the exchanger shell, especially if they are at high temperatures or if there is fouling that makes coupling with contact transducers difficult.

- Application: EMAT is ideal for detecting wall thinning, pitting and cracks in tubes and casings, without the need for couplant. Its ability to work in extreme conditions makes it valuable for in-line or soon after operation inspections.

Remote Visual Inspection (RVI)

- Components: Inside of tubes, shell side (especially in fixed beam exchangers where the beam cannot be removed), tubesheet, gaskets, tube-plate and headers.

- Application: RVI, using borescopes or videoscopes, allows detailed visual inspection of inaccessible areas. It can identify visible corrosion, erosion, fouling, blockages, mechanical damage, or the presence of leaking joints. Drones can be used to inspect the exterior of large exchangers.

Infrared Thermography (IRT)

- Components: Outer casing, pipe connections, tubesheet (in operation) and insulation.

- Application: IRT detects thermal anomalies that may indicate operational or structural problems. For example, it can identify:

- Corrosion Under Insulation (CUI): Cold areas in the insulation indicate the presence of moisture and corrosion.

- Internal fouling or scaling: Irregular temperature patterns in the casing or tubing may indicate areas of restricted flow or deposit buildup.

- Internal or external leaks: Temperature variations may indicate hot or cold fluid leaks.

- Hot spots: In associated electrical systems (pumps, valves), may detect overheating.

These ANDTs applied under the concept of Pressure Vessel Inspection, applied in a strategic manner, allow a comprehensive and proactive monitoring of the exchangers, ensuring their optimal performance and extending their useful life.

To visualize how these inspection techniques are applied in the field, we recommend this video courtesy of Technically Info, which shows actual procedures on heat exchangers in accordance with API and ASME standards:

How to inspect heat exchangers.

Applicable norms and standards (API, ISO, NACE)

Predictive inspection practices are regulated by reference standards:

- TEMA (Tubular Exchanger Manufacturers Association): Specific criteria for the design, manufacture, selection and classification of shell and tube heat exchangers.

- API 660: specific requirements for heat exchangers in refineries.

- ASME BPVC: design and test criteria for pressure vessels.

Key inspection sections:

- ASME BPVC Section VIII, Division 1:

- Regulates equipment operating above 1 bar internal pressure.

- Defines requirements for visual inspections, non-destructive testing (NDT) during and after manufacture and mandatory hydrostatic testing to verify structural integrity prior to commissioning.

- ASME BPVC Section V:

- Establishes the methods and procedures for non-destructive testing (NDT) applicable to pressure vessels, such as radiography, ultrasound, liquid penetrant, magnetic particles, among others.

- ASME BPVC Section IX:

- Regulates the qualification of welding procedures and welders, ensuring that critical welds meet the required standards for integrity and safety.

- ISO 9712: certification of non-destructive testing personnel.

- NACE MR0175 / SP0472: prevention of internal corrosion.

Meeting these standards ensures quality, reliability and safety in industrial operations.

Integrated technology for optimal integrity management

The application of ANDT, together with SCADA systems, drives industrial digitalization. It enables companies such as Aramco, Shell or Petrobras to achieve data-driven reliability. This transforms maintenance from reactive to predictive and proactive maintenance.

The information from these inspections fuels asset management models. This optimizes maintenance intervals and reduces unscheduled downtime. The combination of these technologies is the basis of today’s smart maintenance.

ANDT inspection in exchangers: Mistras Group case

A leading reference in the application of advanced inspection in exchangers is Mistras Group, a leading provider of ANDT services and asset integrity solutions. In projects within the petrochemical and energy sector, Mistras has demonstrated how the integration of advanced techniques allows in-depth diagnosis of internal failures without dismantling.

For example, in an operational case at a hydrocarbon processing plant, Mistras applied a combined approach using eddy current array (ECA), acoustic emission (AET) and remote videoscopy (RVI) to assess the condition of shell and tube type exchangers. This procedure allowed detecting:

- Internal corrosion thinning in straight pipes and U-bends.

- Incipient leaks in tube-plate joints by acoustic activity in hydrostatic tests.

- Deflector damage and deposit accumulation by remote visual inspection.

The intervention enabled a predictive maintenance strategy that prevented an unplanned critical shutdown. In addition, the digitization of the log fed the condition-based reliability models, which increased the thermal efficiency of the system by more than 30% and reduced inspection costs in the next cycle.

This case reaffirms the relevance of advanced NDT methods as part of pressure vessel compliance, aligned with API, ASME BPVC Section V and continuous structural integrity monitoring programs.

Conclusions

Heat exchangers are critical equipment that operate as pressure vessels, subject to standards such as Tema, API 660 and ASME BPVC. Their main components are designed to withstand high pressures, thermal stresses and severe conditions, ensuring safety and reliability in sectors such as Oil & Gas and energy.

To preserve its integrity and useful life, it is key to apply advanced NDT predictive techniques of non-destructive inspection, such as: PAUT, TOFD, ECA, AET and digital radiography, which detect early failures. Coupled with this technological process is NDT with AI, to strengthen analysis and improve responses. These practices optimize predictive maintenance and maximize thermal efficiency in demanding industrial operations.

“Advanced predictive inspection maximizes the integrity and safety of your heat exchangers.”

This article is part of the editorial line of Inspenet, official media partner of global events such as GASTECH, API, AMPP, ASNT and others.

References

- ASME BPVC Section VIII, Divisions 1 & 2: Rules for Construction of Pressure Vessels

- ASME BPVC Section V: Nondestructive Examination

- ASME PCC-2: Repair of Pressure Equipment and Piping

- API 510: Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and Alteration

- API RP 572: Inspection of Pressure Vessels

- API RP 574: Inspection Practices for Piping System Components

- Mistras Group. Heat exchanger tube inspection, repair, coating, and manufacturing services. Available in: https://www.mistrasgroup.com/who-we-help/asset-management/heat-exchangers

- Mistras Group. Eddy Current Inspection Services. Available in: https://www.mistrasgroup.com/how-we-help/field-inspections/traditional-ndt/eddy-current

- Mistras Group. Acoustic Emission Testing. Available in: https://www.mistrasgroup.com/how-we-help/field-inspections/traditional-ndt/acoustic-emission

Frequently Asked Questions (FAQs)

Why is this equipment a pressure vessel?

Casing and tubing models operate with fluids under pressures higher than atmospheric pressure. For this reason, technical standards such as API 660 and the ASME BPVC Section VIII code integrate them into the category of pressurized equipment, which implies strict requirements in terms of design, manufacture and inspection.

What types of heat exchangers are most commonly used?

Mainly casing and tubing are featured, with configurations such as single-pass, multi-pass, floating heads or with U-tubes. These variants are common when high pressure resistance and regulatory compliance are required.

What is advanced NDT and what is its application?

Advanced NDT (non-destructive testing) is a specialized technique for detecting internal anomalies without dismantling the equipment. Their application improves safety, thermal performance and allows precise interventions to preserve system lifetime.

What are the most frequent failure modes in this equipment?

Erosion, fatigue, fouling that decreases heat transfer, vibrations that induce cracks, and corrosion in tube bundles or plates can occur. These defects affect operating efficiency if not detected in time.

What is the purpose of API 660 in this context?

Establish essential guidelines for the design and inspection of thermal equipment in petrochemical plants. Compliance with these guidelines ensures structural and operational reliability throughout the life of the component.

What does infrared thermography (IRT) provide?

This technique allows to visualize temperature variations on the surface of the equipment, revealing problems such as leaks, internal fouling or obstructions without opening the system. It is a key tool for fast and effective diagnostics.

How do ANDTs contribute to predictive maintenance management?

The ANDT application provides reliable data on the internal condition of components, facilitating decisions based on actual condition. This reduces unplanned downtime, improves thermal efficiency and aligns maintenance with smart models.

What is the Eddy Current Array Assay (ECA)?

ECA is an inspection technique that detects corrosion, cracks, pitting and other internal pipe damage. Its ability to perform accurate and fast scans makes it an ideal method in demanding industrial environments.

What other standard applies to the inspection of pressure equipment?

Pressure vessel inspection is governed by standards such as ASME BPVC (Sections V and VIII), TEMA (for design criteria), ISO 9712 (certification of technical personnel) and NACE MR0175, focused on corrosive environments.

What benefits did the Mistras Group case show for ANDT?

The study revealed that applying ANDT allows integrity assessment without disassembling the equipment. This advantage reduces costs, avoids critical shutdowns and allows the establishment of maintenance strategies based on the actual behavior of the equipment.