Table of Contents

- Fundamentals of radiographic testing

- Computed radiography (CR) vs. direct digital radiography (DR)

- How industrial digital radiography works

- Advantages of industrial digital radiography

- Applications by industry sector

- Standards and technical compliance

- Applied technologies and leading manufacturers

- Conclusions

- References

- Frequently Asked Questions (FAQs)

Radiographic testing is one of the most widely used techniques in the field of non-destructive testing (NDT) to detect internal discontinuities without altering the integrity of the material. Its physical principle, based on the differential attenuation of radiation as it passes through solids, reveals defects with high precision.

Today, with the advent of industrial digital radiography, computed radiography (CR) and direct radiography (DR) systems have progressively replaced traditional films, offering instant imaging, digital traceability (DICONDE) and reduced radiological exposure. This breakthrough marks a turning point in the modern inspection and quality control industry.

Fundamentals of radiographic testing

Radiographic testing uses ionizing radiation (X-rays or gamma rays) to examine the internal structure of a component.

When a beam of radiation passes through a material, its intensity decreases according to the law of exponential attenuation, which depends on the density, thickness and composition of the object. A discontinuity, such as cracks, porosity or inclusions, alters this behavior, generating a visible contrast in the image.

Most common sources and detectors:

- Radiation sources: X-ray tubes, Iridium-192 (Ir-192), Cobalt-60 (Co-60).

- Classical detectors: silver halide film.

- Modern detectors: phosphor plates (CR) and digital flat detectors (DR).

Evolution of radiographic testing

Since the discovery of X-rays by Wilhelm Conrad Röntgen in 1895, radiographic testing has advanced from a scientific experiment to become one of the main tools for quality control in multiple industries.

During the first decades of the 20th century, silver halide film radiography enabled the first inspections of metal and railway components. With the industrial expansion of the 1940s and 1960s, portable gamma sources such as Iridium-192 and Cobalt-60 emerged, facilitating radiographic inspection in the field and increasing coverage in pipelines and pressure vessels.

In the 1980s and 1990s, the digital transition began with the introduction of computerized radiography, which eliminated developing chemicals and improved productivity.

Starting in 2000, the advent of direct digital radiography consolidated the technological leap with instantaneous detection, analysis software and DICONDE traceability. To fully understand this paradigm shift in NDT inspection, it is necessary to distinguish between the two technologies leading the way in digitization: computerized and direct radiography.

Today, radiographic testing is an integral part of Industry 4.0, integrating artificial intelligence, machine learning and IoT to achieve automated, safe and sustainable inspections.

Computed radiography (CR) vs. direct digital radiography (DR)

The transition to industrial digital radiography brought with it two main approaches, both of which retain the physical principles of radiographic testing, but with more advanced detection and processing technologies.

| Characteristic | Film radiography | Computed radiography (CR) | Digital radiography (DR) |

| Capture medium | Silver halide film | Photostimulable phosphor plate | Digital flat detector |

| Processing | Chemical development | Laser scanning | Direct conversion to digital signal |

| Procurement time | Hours | Minutes | Immediate |

| Reusability | No | Yes (up to 1000 times) | Permanent |

| Traceability (DICONDE) | No | Yes | Yes |

| Resolution | High, but limited | High | Very high |

| Radiological exposure | High | Medium | Low |

| Environmental maintenance | Chemical use | Chemical free | Chemical free |

| Automation possible | No | Partial | Total |

As a technical summary, direct DR offers the best industrial performance: higher speed, lower dose, IoT integration and artificial intelligence support. CR acts as an ideal transition from analog systems to full digitization.

How industrial digital radiography works

This technology employs highly efficient sensors that transform radiation into electronic signals, processed by specialized software. In CR, the latent image is recorded on a phosphor plate and then read by a laser scanner. In DR, the flat detector converts the radiation directly into digital data in real time, eliminating the scanning step.

Both systems allow:

- Digital adjustment of brightness, contrast and zoom.

- Integration with DICONDE databases for traceability.

- Automated analysis by machine learning for defect detection.

- Communication with predictive maintenance platforms or Digital Twin.

Advantages of industrial digital radiography

Modernization of radiographic testing using digital technologies such as CR and DR maintains a more skillful and improved approach to the way non-destructive inspection is performed. These solutions bring the following technical, operational and environmental benefits that improve the quality and traceability of results:

- Immediate results: DR systems allow images to be obtained and displayed in seconds, drastically reducing radiographic inspection times and increasing productivity in continuous production environments.

- High resolution and sensitivity: Digital detectors offer a wider linear response and superior dynamic range, making it easier to detect subtle defects with sub-millimeter accuracy even in high-density materials or complex geometries.

- Reduced radiation exposure: Digital sensors require lower radiation doses to achieve quality images, increasing personnel safety and reducing fatigue of the emitting equipment.

- Sustainability and waste reduction: By eliminating the use of film, developer chemicals and photo baths, DR contributes to a cleaner, more sustainable work environment with less environmental impact.

- Full traceability and regulatory compliance: Images are stored with technical metadata under DICONDE, ISO 17636-2 and ASTM E2446 standards, enabling accurate tracking of inspection history and ensuring compatibility between equipment and platforms.

- Digital integration and industrial automation: Modern systems communicate with NDT 4.0 networks, predictive maintenance platforms and artificial intelligence, optimizing workflows and enabling automated image interpretation.

- Comparative and predictive analysis: Continuous digital recording allows comparing results between inspection periods, detecting degradation patterns and generating predictive models based on material performance and behavior.

Applications by industry sector

Industrial digital radiography has revolutionized radiographic inspection practices in industries where structural integrity, safety and traceability are paramount. Thanks to advanced systems it is now possible to perform assessments with greater sensitivity, lower exposure and automated analysis in multiple industrial environments.

- Welding and piping inspection to detect internal defects such as porosity, slag inclusions, lack of fusion, laminations and localized corrosion.

- Pipeline, pressure vessel and transfer line monitoring under standards such as ASME Section V and API 1104, ensuring regulatory compliance and operational safety.

- Metallic and composite coating verification, detecting subsurface failures or corrosion coating de-bonding.

- Structural integrity evaluation in the field, even in conditions of high humidity, temperature or controlled environmental radiation.

- Evaluation of composite materials (CFRP/GFRP), adhesive joints and TIG or friction stir welds (FSW), where digital resolution allows detection of delaminations and internal cracks.

- Quality control on critical components such as blades, fuselages, pressurized tanks, cryogenic tanks and engine sections.

- Inspection of additively manufactured parts (3D printing) to verify internal homogeneity and the absence of micro-defects in light alloys.

- Application of portable digital radiography, allowing on-site inspections without the need to disassemble structures.

Manufacturing, metallurgy and foundry

- Dimensional and structural control in castings, forgings and machined parts, ensuring uniformity, density and absence of inclusions.

- Verification of thickness and internal homogeneity in heat-treated or precision welded components.

- Automated inspection on production lines, where DR systems allow immediate detection of defects and rejection in real time.

- Optimization of metallurgical processes, using digital comparative analysis between batches or manufacturing campaigns.

Energy, nuclear and critical infrastructure

- Supervision of welds, boilers, turbines and steam lines in thermoelectric and nuclear power plants.

- Digital NDT predictive inspection of valves, exchangers and high pressure systems, using DICONDE images for historical comparison.

- Structural integrity verification in harsh environments, where portable and robotic DR systems allow for reduced exposure and increased accuracy of results.

- Remote and automated assessment, integrating images in predictive maintenance platforms and Digital Twin models for advanced diagnostics.

Non-industrial applications

- Art and archeology: internal examination of paintings, sculptures and artifacts without damaging them, revealing hidden structures or restoration processes.

- Forensic medicine: analysis of skeletal remains and encapsulated objects without direct manipulation, preserving evidence in technical investigations.

- Electronics and microcomponents: verification of BGA soldering, microchips and internal connections on PCB boards by high resolution radiography.

- Additive manufacturing: quality control of 3D printed parts to detect porosity, fusion failures or defective internal geometries.

The application of industrial digital radiography in all these sectors – industrial and non-industrial – combines metrological accuracy, radiation safety, digital traceability and operational efficiency, consolidating it as an essential tool within non-destructive inspection (NDT) programs and modern mechanical integrity management.

Standards and technical compliance

The severity of digital radiographic testing is based on international standards that guarantee quality, safety and traceability:

- ASTM E1030 / E1742: general requirements for radiographic examinations.

- ASTM E2446 / E2736: technical evaluation of CR and DR systems.

- ISO 17636-1 / 17636-2: film (1) and digital (2) radiography of welds.

- DICONDE (Digital Imaging and Communication in Non-destructive Evaluation): digital traceability and standardized storage.

- ASNT SNT-TC-1A / ISO 9712: qualification and certification of NDT personnel.

These standards support the reliability of the process and the technical competence of operators certified at levels I, II and III.

Applied technologies and leading manufacturers

Innovation in industrial digital radiography combines next-generation hardware and software, which have enhanced the accuracy, portability and traceability of NDT inspections.

Main developments and manufacturers:

- Carestream NDT, a leading player in industrial digital radiography, is driving the transition to high-performance DR (Digital Radiography) systems with the INDUSTREX HPX-ARC series. These bendable direct radiography (bendable DR) detectors provide high-resolution images (up to 98 µm) with instant processing and without the use of film or development chemicals. Carestream has integrated the HPX-ARC into its INDUSTREX Digital Viewing Software ecosystem, which allows viewing, measuring, and storing images in DICONDE format, ensuring traceability and regulatory compliance with ASTM E2446, ISO 17636-2, and ASME Section V standards.

- Waygate Technologies (Baker Hughes) is another leader in industrial digital radiography solutions with its DXR line of high-sensitivity portable detectors and CRx Vision systems. Its equipment enables field inspections with wireless connectivity, instant processing, and DICONDE traceability. Integrated with Rhythm Insight software and AI-powered automated analysis tools, it provides accurate assessment of welds, castings, and critical components. Its compliance with ASTM E2736e and ISO 17636-2 standards ensures reliable results across various energy sectors.

- Vidisco develops portable DR digital radiography systems designed for industrial and security environments. Its Guardian Elite series offers lightweight wireless detectors with extended battery life, integrated battery, and real-time Wi-Fi communication. Vidisco VEO software allows you to view and calibrate high-resolution radiographic images stored in DICONDE format. These solutions are robust, weather-resistant, and quick to set up.

- DÜRR NDT stands out for its focus on high-precision CR and DR, integrating hardware and software under a fully DICONDE-compatible ecosystem. Its HD-CR 35 NDT scanner and D-Tect X software enable superior resolution imaging and advanced inspection data management in accordance with ASTM E2446e ISO 17636-2. Designed for laboratory or field use, its systems offer immediate diagnostics and automated calibration.

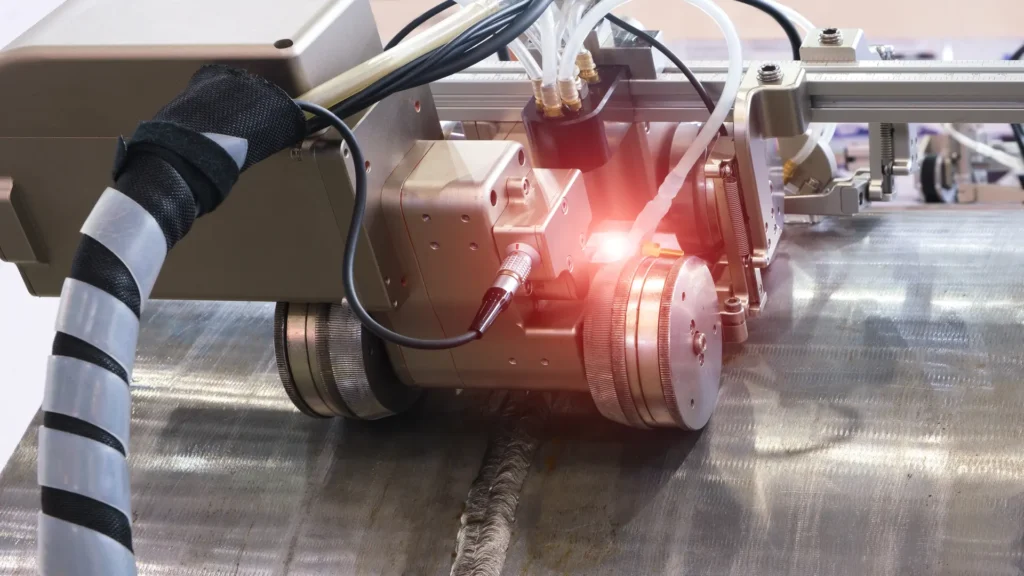

- 3E NDT: presented its innovative Xpress Flex Bendable DR System, a flexible digital panel capable of adapting to curved surfaces (such as pipes and fuselages), eliminating edge losses and achieving complete captures without repositioning. Together with the XpressScan + XVU system, sequential scans are automated, generating high-resolution panoramic images and continuous views. These solutions, combined with a portable 200 kV battery-operated X-ray tube, facilitate digital inspection in the field without electrical infrastructure. The following video shows a demonstration of these technologies during ASNT 2025.

Conclusions

Radiographic testing, from analog systems to industrial digital radiography, has established itself as an essential tool in modern non-destructive testing. Advances in CR and DR, together with the integration of artificial intelligence, DICONDE, and Industry 4.0, have raised the standards of accuracy, efficiency, and sustainability in quality control.

Beyond detecting defects, digital radiography is now a cornerstone of predictive maintenance, structural traceability, and operational safety, making it a strategic investment for comprehensive industrial asset management.

References

- Carestream. (s.f.). NDT Solutions. https://www.carestream.com/en/us/nondestructive-testing-ndt-solutions

- DÜRR NDT. (s.f.). What is CR Technology? https://www.duerr-ndt.com/products/computed-radiography/what-is-cr-technology.html

- Espectrometría. (s.f.). Radiografía Industrial – Avances y Aplicaciones en la Industria Moderna. https://espectrometria.com.mx/radiografia-industrial-avances-y-aplicaciones-en-la-industria-moderna/

Frequently Asked Questions (FAQs)

What is the difference between CR and DR radiography?

CR requires scanning of the phosphor plates after exposure; DR directly converts radiation into an instant digital signal.

Why is industrial digital radiography safer?

Because it uses more sensitive detectors, reducing the radiation dose and eliminating toxic chemicals from the development process.

What advantages does DR offer over the traditional film method?

Greater speed, lower exposure, digital traceability, and the possibility of automated analysis using artificial intelligence.

Where is digital radiographic testing mainly used?

In sectors such as oil & gas, aerospace, manufacturing, nuclear, and metal construction.

How to choose between computed radiography (CR) and direct digital radiography (DR)?

The selection depends on the type of component, thickness, inspection frequency, and level of automation required. CR is ideal for progressive transitions, while DR maximizes efficiency and digital traceability.