During the PANNDT event, recently held in the Niagara Falls region, the Inspenet team had the opportunity to talk with Derik Dalton, Director of Business Development at 3E NDT, a US company with half a century of experience in non-destructive testing (NDT) solutions. The meeting allowed to explore first-hand the advances that the company is leading in the field of digital radiography NDT, especially in scenarios with critical conditions or limited access.

During the interview, Dalton highlighted how international regulations, particularly in Europe, are driving the adoption of technologies that reduce radiation exposure levels.

Our digital panels are able to do that, they're much faster, so the exposure to X-rays, gamma and things like that go down, and regulatory compliance really wants to reduce everyone's exposure.

Derik Dalton.

This approach is aligned with the evolution of the industry, which demands safer, more efficient results with immediate digital traceability. Stricter regulations in Europe are setting a path that North America is beginning to follow, and 3E NDT is positioned to serve both geographies with solutions aligned to those regulatory frameworks.

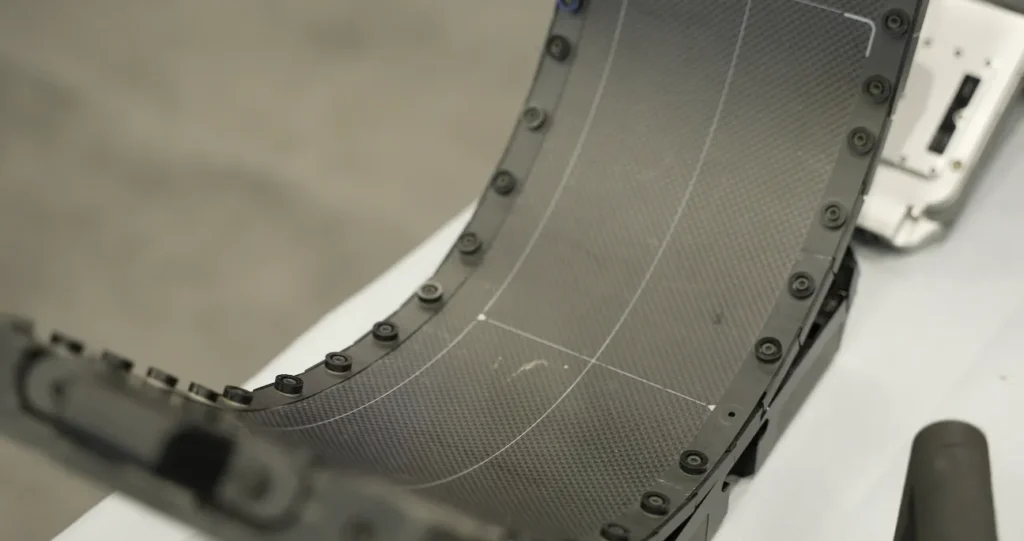

One of the most striking developments is the flexible X-ray panel, Xpress Flex, a tool that allows the sensor to be adapted to the contour of a circular weld. Unlike traditional rigid panels, this device is based on flexible sensing technology with a curvature that improves the coupling between the inspected surface and the detector.

This design not only avoids edge contact loss, a common problem with flat panels, but allows full image coverage without geometric distortion, facilitating inspection of complex components without the need for multiple exposures or panel relocation. The panel's ability to record accurate data from different angles with a single exposure makes it a key tool for hazardous environments where time is a critical factor.

Systems integration is also part of 3E NDT's strategy and with its XpressScan solution, an automated manual pipeline system, and XVU software, the company has been able to streamline the image capture and analysis process.

XpressScan works as a digital scanner that manually or automatically scans the surface of a pipe or circular structure, capturing multiple sequential images at high speed. The speed of image acquisition reduces inspection times significantly, minimizing exposure and maximizing coverage without compromising resolution.

The XVU software acts as the core of the data processing and interpretation and digitally stitches together the images captured by XpressScan, creating a continuous, panoramic view of the inspected area. This functionality eliminates the need for manual reconstruction and ensures uniformity in the final image, which is vital for accurate and traceable evaluations.

The transition from traditional film systems to digital solutions can generate resistance among inspection technicians, which is why the company has designed a training program aimed at facilitating this adoption.

This program combines online modules with hands-on sessions, and is aimed at technicians who are used to working with traditional radiographic films, with the objective of understanding the operation, benefits and best practices of using digital radiography. When purchasing a digital panel from 3E NDT, the customer receives free access to two certified courses

With more than 50 years of experience, 3E NDT continues to demonstrate that the future of nondestructive inspection lies in the convergence of adaptable technology, ongoing training and industry collaboration. Its focus on solutions such as the flexible X-ray panel, Xpress Flex reflects a commitment to safety, efficiency and global regulatory compliance.

Digital NDT radiography is not simply a technical improvement, but a transformative tool that redefines industrial inspection in demanding environments.

For more content on PANNDT 2025, visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.