In the framework of PANNDT, one of the most relevant events for non-destructive inspection, the Inspenet team had the opportunity to talk with Gilles Stevens, CEO of Scanna MSC, who shared the vision of the company and its evolution from the defense sector to industrial inspection. With more than 25 years of experience in the development of NDT X-ray technologies for critical scenarios, Scanna has found in the nondestructive testing market a space where its proposal takes on a new dimension.

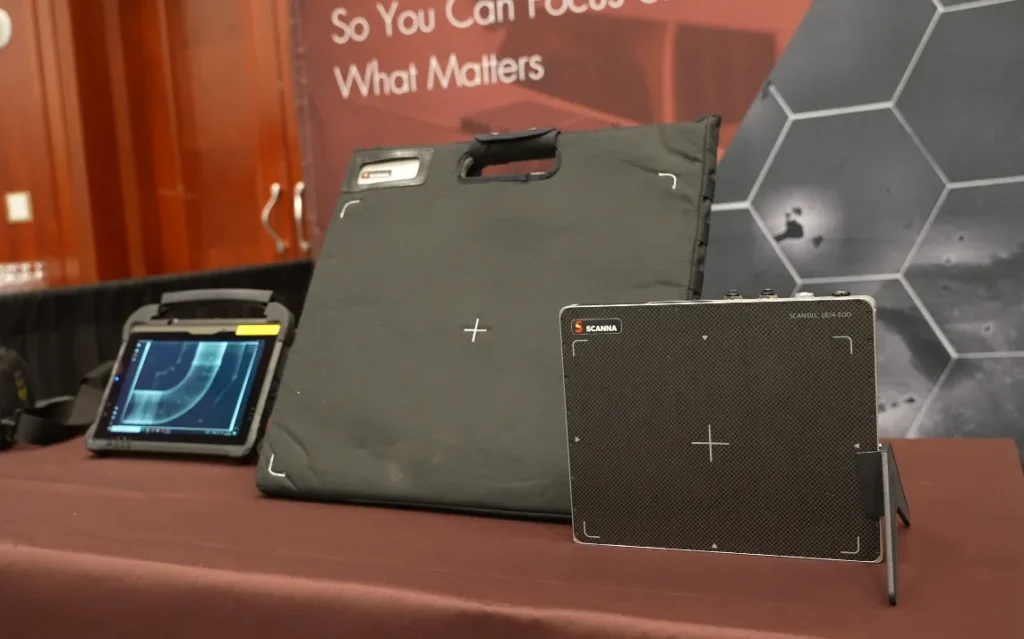

Founded in London, Scanna MSC positioned itself as a provider of portable X-ray solutions for military forces, bomb squads and security agencies. Its reputation was built on reliable, compact, high-resolution products, used in more than 100 countries by organizations such as the UK Ministry of Defense, the US Department of Defense and NATO forces.

Recently, the company has transferred that experience to the industrial sector, offering NDT X-ray solutions for applications as varied as quality control, weld inspection and rope access services. The transition has been natural, as the same attributes that make equipment valuable in a threat context are also crucial in industrial environments that demand portability, speed and reliability.

Recently, the company has extended that expertise to the industrial sector, offering NDT X-ray solutions for applications as varied as quality control, weld inspection, and rope access services. The transition has been a natural one, as the same attributes that make equipment valuable in a threat environment are also crucial in industrial environments that demand portability, speed, and reliability.

The company currently has offices in London and Sarasota (Florida), as well as a technical laboratory in Michigan, which allows them to cover the American market, complementing their already strong network in Europe and Asia.

Scanna's focus is on designing NDT digital radiography equipment that is easy to deploy, lightweight, robust and completely autonomous, with the aim of facilitating the operator's work. In addition, they seek to meet the most demanding international standards in terms of image quality and radiation safety, plus battery autonomy and wireless connectivity complete the profile of a product designed for today's industrial environments.

One of the most illustrative cases mentioned by Gilles Stevens was that of a high-altitude inspection application with rope access. In this situation, the operator needed to climb with all the equipment on his back and the company provided a solution packaged in a lightweight, armored bag, allowing the technician to perform his task without sacrificing safety or image quality. This bag included custom compartments for the X-ray generator, digital panel and protective accessories, allowing for ergonomic and balanced transport during the ascent.

A fundamental part of Scanna's value proposition lies in its support structure, which unlike other companies that deliver the product and disengage, they accompany their customers throughout the adoption and use process, including on-site or remote training, technical assistance and preventive maintenance.

The company works with a network of local distributors and specialists in each region, allowing it to operate efficiently even in different time zones. This philosophy reinforces customer confidence and ensures that every piece of industrial X-ray is utilized to the maximum of its capabilities.

We work with numerous distributors around the world. We have specialized salespeople, and when we sell a product, Scana not only sells a product, but also offers comprehensive support.

Gilles Stevens.

Scanna MSC is not simply a technology manufacturer, it is a company that has made user experience its priority, and understands that in modern industry, every minute counts. Its NDT X-ray equipment enables faster, more accurate and safer inspection, which translates into less downtime, higher quality in production processes and better conditions for operators in both military and oil industries.

Ultimately, the story told by Gilles Stevens at PANNDT is not just that of a company that evolves, but of a philosophy that prioritizes real utility over unnecessary complexity. In a world where technology can become an end in itself, Scanna reminds us that the real goal is to make the operator's life easier, safer and more productive.

For more content on PANNDT 2025, visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.