Table of Contents

The evaluation of hydrogen materials in environments where this gas is present is fundamental for several reasons, mainly related to the safe and efficient use of hydrogen as an energy carrier and raw material.

As the world moves towards more sustainable energy sources, hydrogen is becoming a key player in a variety of applications. It is used in fuel cells, hydrogen storage systems and as a reducing agent in industrial processes, spanning several sectors, including energy, automotive and aerospace.

Hydrogen, due to its small atomic size and high diffusivity, represents a significant problem for the structural integrity and performance of materials. Therefore, it is necessary to perform constant evaluations of materials in environments with high concentrations of hydrogen to identify and mitigate corrosion damage associated with hydrogen embrittlement..

Research on hydrogen corrosion mechanisms is important for understanding hydrogen interactions with materials, leading to the development of more effective prevention methods. A systematic approach will not only improve materials design, but will also help establish guidelines and standards that promote best practices in the implementation of hydrogen-related technologies.

Equipment selection is influenced by the specific properties and conditions under which the materials will be tested. Various types of laboratory equipment and test methods can be adapted for use in hydrogen environments. The following is a summary of some key equipment and techniques:

- High pressure and temperature hydrogen equipment: Pressure vessels, reactor systems and autoclaves for exposing materials to hydrogen under controlled conditions of temperature and pressure.

- Mechanical testing equipment: Tensile testing machines evaluate the mechanical properties of materials; fatigue testing equipment analyzes how materials behave under cyclic loading in hydrogen; and impact testing machines analyze the ductility and toughness of materials.

- Corrosion test equipment: Electrochemical cells to study the corrosion behavior of materials in hydrogen and/or acid environments.

- Hydrogen embrittlement testing equipment: Hydrogen loading/unloading systems are used to test the effect of hydrogen on the mechanical properties of materials, and slow strain rate testing (SSRT) equipment can study hydrogen embrittlement by subjecting materials to slow strain rates in a hydrogen environment.

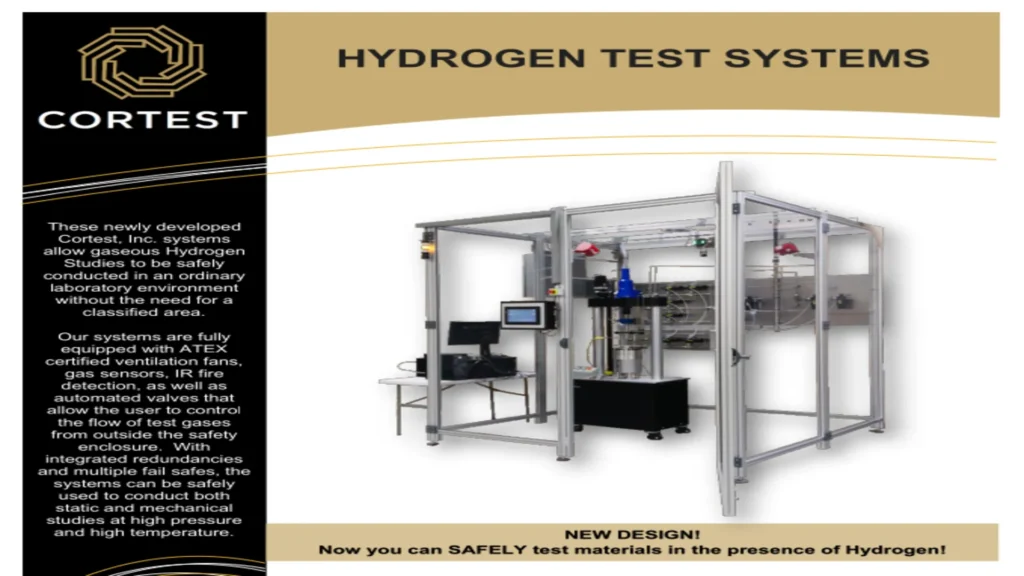

CORTEST hydrogen test system (“The Enclosure”)

Development, production and delivery of the system took approximately three years. However, the project now available can be customized to meet specific customer needs. It was created to help evaluate materials under conditions relevant to hydrogen exposure and its related effects.

The system provides an extensive framework for performing mechanical and electrochemical testing of materials in controlled hydrogen environments. By simulating operating conditions, this equipment allows researchers and engineers to evaluate the resilience of different alloys and composites, providing information on their long-term performance and reliability.

These systems offer a choice between two test methods, described below:

- Static autoclave system for testing at elevated temperatures and pressures. Constant displacement specimens are used for these tests, and the system follows ASTM E1681.

- Autoclaved load frame system used for high temperature and pressure fatigue testing as well as tensile testing. The system follows ASTM E647, G142 or G129 standards.

A special safety cabinet or enclosure was developed to house the test systems and ensure safety. This cabin is equipped with safety devices such as hydrogen monitoring, hydrogen flame detection, and pressure-based leak detection. In addition, the cabinet has ventilation systems to ensure that the laboratory environment is safe.

An external control panel can turn off power to all unclassified electrical equipment, vent the test gas and increase ventilation if a leak or flame is detected to monitor and manage safety systems. The cabinet also features a pressure booster system and an automated pneumatic valve panel, allowing the vessel to be pressurized remotely. Leak testing and cyclic purging are essential safety procedures to prevent hydrogen and oxygen from mixing; these steps must be performed before introducing hydrogen into the test system and after performing a test.

The autoclave used for Compact Tension (CT) sample testing is static and is equipped with a glove box and an air purification system. This helps to create an inert environment for long duration constant displacement static testing, which can be performed close to room temperature. The autoclave is designed to withstand working pressures up to 30 MPa (4,350 psi) and temperatures up to 300 °C (572 °F).

The load frame has a load capacity of up to 50 kN and can be used for various tests such as fatigue, slow strain rate, static constant load, increasing load and programmable load tests. In addition, the load frame has a system for crack initiation testing and accurate crack growth measurement using the DCPD technique.

The use of advanced laboratory equipment is necessary for academic research and industrial applications, where the safety and efficiency of systems using hydrogen are critical. Through the systematic evaluation and characterization of materials exposed to hydrogen, Cortest’ s equipment is a crucial tool in ongoing efforts to improve material performance and safety standards in high hydrogen environments.

This article was developed by Cortest and published as part of the fourth edition of Inspenet Brief magazine December 2024, dedicated to technical content in the energy and industrial sector.