Table of Contents

Introduction

The work of an underwater welder is a high-risk profession that involves performing welding tasks underwater. Masters of the trade, these operators must combine technical proficiency with a deep understanding of the hazards around them to perform complex welds in a hostile environment.

“Hazards of Underwater Welding” explores the realities of this dangerous occupation, delving into the dangers and challenges faced by these skilled workers beneath the waves. From electrical shock to insecurity to decompression sickness, this article examines the types of risks in underwater welding and the mortality rate in underwater welding, offering a comprehensive look at the challenges these professionals face.

Context of the profession of an underwater welder

Being an underwater welder requires a combination of subject matter knowledge, experience, professionalism, technical welding skills, and diving skills. These professionals work in extreme conditions, repairing subsea structures, pipelines, and oil platforms, among other tasks.

This profession is one of the most dangerous jobs in the world, with a mortality rate of 15%, requiring up to two years of training. It is estimated that the average life span of an underwater welder is around 35 to 40 years. These data indicate why the profession is very dangerous.

This profession demands exceptional endurance and strength, and is reserved only for those welders who are truly committed and capable. The most experienced and respected professionals in this field can earn between $200,000 and $300,000 a year, reflecting not only their skill, but also the risk and dedication involved in this profession. In addition, the harder they work, the greater their professional growth and, consequently, their income.

Underwater welding safety: Risks, accidents and fatality rates

- Importance of the topic: Understanding the risks of subsea welding and the fatality rate in subsea welding is vital to improve safety conditions and reduce maritime occupational accidents. This not only protects workers, but also ensures the integrity of subsea infrastructures.

- Marine occupational accidents: Marine occupational accidents, which include those related to subsea welding, are events that can have devastating consequences. The most common accidents in subsea welding include:

- Drowning: Water pressure and limited visibility can increase the risk of drowning during welding operations.

- Explosions: Flammable gases and sparks from welding can cause underwater explosions.

- Electrocutions: The presence of water and the use of electrical equipment increase the risk of electric shocks.

- Poisoning: Inhalation of toxic gases and welding fumes can cause poisoning.

- Mortality Statistics: Statistics show that the mortality rate in underwater welding is significantly high compared to other professions. According to the International Association of Underwater Welders, mortality in this profession is approximately 13 per 1,000 workers annually.

- Comparison with other professions: Comparing this fatality rate to other high-risk professions, such as mining or construction, shows that underwater welders face a significantly higher risk due to the combination of unique hazardous factors in their work environment.

Factors or types of risks in underwater welding

Underwater welding presents a unique set of risks and hazards to the underwater welder that are different from those found in traditional welding environments. One of the main hazards is the extreme water pressure that can affect the human body and equipment. Welder-divers are exposed to immense pressure as they descend deeper into the ocean, which can lead to physical discomfort and, in severe cases, decompression sickness. The following are the most common factors:

- Decompression: Improper decompression is a common cause of fatal accidents among underwater welders. Rapid decompression can lead to decompression syndrome, which is potentially lethal.

- Hostile environment: The underwater environment presents unique hazards such as water pressure, limited visibility and dangerous marine life. These factors significantly increase the risks of underwater welding.

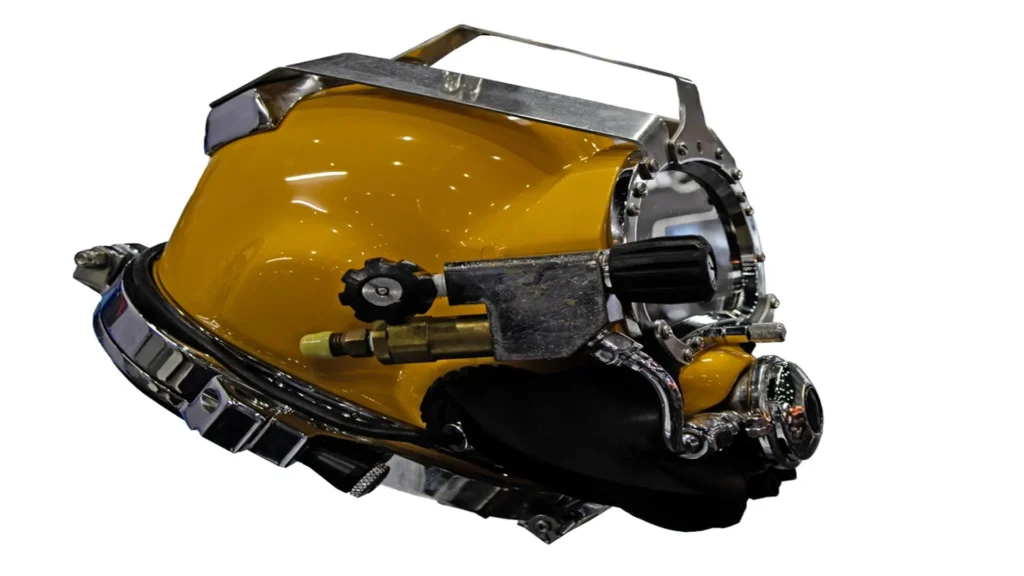

- Equipment failures: Failures in welding equipment or diving systems can be fatal. Malfunctioning breathing equipment, for example, can lead to asphyxiation. Figure 1 shows the diving equipment, offshore marine helmet, insulated on white background, yellow color, with external neck clamp and yucca clamp and locking system, as basic elements of the underwater welder’s diving equipment.

- Human errors: Human errors, such as failure to follow safety procedures, stress or fatigue, also contribute to underwater welding risks.

Safety measures and prevention strategies.

In order to mitigate the risks and dangers inherent to underwater welding, progress is being made in reviewing all the variables that may affect this process and thus be able to perform the construction and maintenance work of these critical underwater infrastructures safely and ensuring the health and life of this welder. The following are some of the strategies that are being applied:

- Safety procedures: Implementing strict safety procedures is essential to minimize risks in underwater welding. This includes proper decompression protocols and correct use of equipment.

- New underwater welding techniques: A common method is to use a hyperbaric chamber. Imagine a sealed room filled with a special pressurized gas, as if you were at the bottom of the sea, but without getting wet! This method allows for controlled welding environments, reducing exposure to external hazards and providing a safer alternative to traditional underwater welding.

- Technological innovations: New technologies, such as advanced wetsuits and real-time monitoring systems, are significantly improving the safety of underwater welders.

- Technology and equipment: The use of state-of-the-art equipment, such as underwater robots and remote monitoring systems, can minimize the risks of underwater welding. These technological advances help reduce welders’ direct exposure to hazardous situations.

- Training and certification: Proper training and certification are crucial. Subsea welders must be well trained to handle emergency situations and familiar with the latest safety equipment. For more information on this topic see the following video courtesy of WeldTube:

What Does it Take to Be an Underwater Welder?

- Regulations and standards for underwater welding procedures and protocols: The establishment of strict standards and procedures for all underwater welding operations is essential. These protocols should be regularly reviewed and updated to reflect best practices and technological advances.

Industry standards for underwater welding are continually evolving to incorporate the latest technological advances, best safety practices and environmental considerations.

Some examples of these standards

- AWS D3.6 Underwater Welding Code: An international benchmark developed by the American Welding Society (AWS) that establishes requirements for welder qualification, welding procedures and quality control in underwater welding.

- ISO 14164 Standard: Provides guidelines for the selection, training and assessment of underwater welders.

- DNV GL Standards: Establish criteria for underwater welding on marine and offshore structures, including oil platforms and offshore wind farms.

- Supervision and control: The implementation of supervision and control mechanisms ensures compliance with safety standards. Regular inspections and safety audits are vital to identify and correct potential failures before incidents occur.

Psychological effects:

- Psychological effects: The work of an underwater welder can have a significant emotional and psychological impact due to the isolation and hazardous nature of the tasks.

- Support and resources: Adequate resources for the psychological support of subsea welders, such as counseling programs and mental health services, are essential.

Conclusions

The profession of underwater welder is one of the most risky, but with the understanding of the types of risks in underwater welding and the implementation of safety measures, it is possible to reduce the mortality rate in underwater welding and improve the working conditions for these brave professionals.

It is very important that companies and organizations are committed to continuously improve the working conditions and safety of underwater welders. Collaboration between industry and regulators is necessary to establish and maintain high safety standards.

Technological advances and best practices adopted in the industry promise a safer future for subsea welders. With a continued focus on innovation and safety, it is possible to significantly reduce the subsea welding fatality rate and create a safer working environment for all.

Join the fight for the safety of underwater welders!

References

- ladbible.com

- Jobs Now

- National geographic