Table of Contents

- From automated NDT to NDT 4.0

- Evolution of non-destructive testing (NDT)

- Key technologies: Automation towards NDT 4.0

- Comparison: Traditional vs. automated NDT methods

- The relation between NDT Automation, Industry 4.0 and NDT 4.0

- Benefits of automated NDT and its impact on Industry 4.0

- Future prospects in Industry 4.0

- Conclusions

- Frequently Asked Questions (FAQs)

NDT automation is transforming industrial inspection processes by integrating artificial intelligence (AI), robotics and predictive analytics into asset management. In the era of Industry 4.0, these technologies enable non-destructive testing with greater accuracy, speed and safety, reducing human dependence and increasing operational reliability.

The adoption of automated systems marks a step change in maintenance engineering. The use of digital twins, real-time data and IIoT connectivity drives a predictive model that maximizes efficiency, safety and profitability in industrial operations.

From automated NDT to NDT 4.0

The evolution towards NDT 4.0 represents the meeting point between Non-destructive Testing automation and industrial digital transformation. While automation optimizes non-destructive testing through robotics and artificial intelligence, NDT 4.0 expands the scope by connecting systems, analyzing data in the cloud and applying predictive algorithms that turn inspection into a continuous, cognitive process.

This transition is supported by technologies such as IIoT, Big Data, digital twins, machine learning and cloud computing, which allow the creation of fully connected inspection ecosystems. Thanks to them, industrial maintenance shifts from reactive to predictive and risk-based, integrating inspection within the complete asset reliability cycle.

Evolution of non-destructive testing (NDT)

Traditional methods

Traditional non-destructive testing (NDT), such as ultrasonic, industrial radiography, magnetic particle or liquid penetrant inspection, has been essential to ensure the integrity of critical components. However, they require manual interpretation by specialized technicians and can have variations in results due to the human factor.

Transition to automation

With digital transformation, NDT automation emerges in response to the need for greater accuracy and repeatability. Today’s systems combine intelligent sensors, autonomous robots and AI algorithms capable of analyzing large volumes of data without direct intervention, enabling immediate diagnostics and proactive maintenance actions.

Key technologies: Automation towards NDT 4.0

Robotics and industrial drones

Robotics applied to non-destructive testing (NDT) is one of the most disruptive innovations. Crawler-type robots inspect pipelines, tanks or boilers using ultrasonic sensors, while drones equipped with thermal or infrared cameras allow the evaluation of elevated or difficult-to-access structures. These technologies improve safety, reduce inspection times and increase operational coverage.

NDT robotic systems enable the automation of ultrasonic inspection in complex industrial environments, integrating accuracy, safety, repeatability and high speed analysis as part of Industry 4.0 integration, ensuring consistent and traceable results.

Artificial Intelligence and Machine Learning

Systems based on AI and Machine Learning process signals, images and structural data in seconds. Using trained models, they identify defects, cracks or corrosion with higher accuracy than human visual inspection. In addition, they integrate predictive analytics that anticipate failures before they occur, optimizing industrial maintenance planning.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) connects equipment, sensors and management platforms through secure networks. This interconnection enables remote monitoring, generation of historical databases and risk-based decision making (RBI, Risk-Based Inspection). Leading companies apply IIoT to optimize traceability and regulatory compliance (API 580, ISO 55000).

Digital twins and structural simulation

The digital twin is a virtual replica of the physical asset that reproduces its behavior under real operating conditions. In NDT automation, this tool makes it possible to visualize internal defects, simulate stresses and anticipate material degradation. Thanks to integration with AI and deep learning, digital twins offer essential analytical support for asset integrity management.

As shown in the figure below, the use of digital twins allows the structural behavior of industrial assets to be visualized in real time.

Advanced instrumentation and smart sensors

PAUT (Phased Array Ultrasonic Testing), TOFD (Time-of-Flight Diffraction) and Computed Radiography (CR) technologies enable high-resolution inspections and more reliable analysis. These methods, combined with automated systems and assisted interpretation software, provide accurate data that strengthen technical decision making and plant reliability.

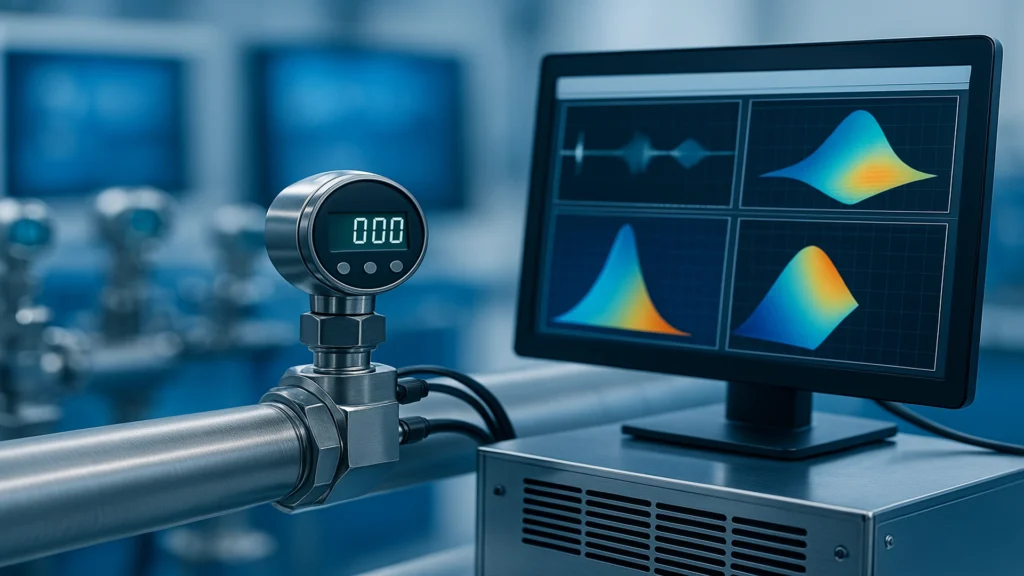

In Figure 2, a waveform instrumentation for continuous monitoring of long pipeline lengths is shown as an example of integration of advanced NDT to Industry 4.0.

Comparison: Traditional vs. automated NDT methods

| Aspect | Traditional NDT | Automated NDT |

| Human intervention | High | Minimal (remote monitoring) |

| Inspection speed | Slow, operator dependent | High, in real time |

| Result accuracy | Variable | Consistent and quantifiable |

| Occupational safety | Risks in the field | Minimal risk (robots and drones) |

| Data management | Manual or local | Digital and centralized |

| Operating cost | High for time and personnel | Optimized for efficiency |

| Predictive application | Limited | Fully integrated |

The relation between NDT Automation, Industry 4.0 and NDT 4.0

| Approach | Definition | Technological level | Main objective |

| NDT automation | Application of robotics and algorithms for inspection without human intervention. | Mechanical-digital | Efficiency and repeatability |

| Industry 4.0 | Framework for digitization and total connectivity of industrial processes. | Connective ecosystem | Integration and smart control |

| NDT 4.0 | Digital transformation of NDT through AI, IIoT and digital twins. | Cognitive-predictive | Reliability and smart maintenance |

Benefits of automated NDT and its impact on Industry 4.0

Oil and gas sector

In this sector, NDT automation is applied in the inspection of pipelines, offshore platforms and storage tanks. Robots equipped with ultrasonic or magnetic sensors detect corrosion, cracks and loss of thickness, while AI analyzes trends to prevent leaks and catastrophic failures, aligning with API 653 and API 580 integrity practices.

These systems also allow corrosion mapping of pipelines and tank floors, improving early detection of thickness losses and enhancing risk-based inspection (RBI).

The advancement of “NDT automation” has made it possible to perform high-resolution inspections in complex environments.

As shown in the figure below, “robot crawlers” and “industrial drones” equipped with PAUT and TOFD technologies perform accurate and traceable tests on pipelines and storage tanks.

Case Study 1: In oil and gas, ROSEN Group and Applus+ RTD implement NDT with crawler robots and drone-based NDT for internal and external inspections on pipelines and storage tanks. Thanks to the combined use of PAUT (Phased Array Ultrasonic Testing) and TOFD (Time-of-Flight Diffraction), the companies achieve high-resolution inspections in less time and with greater traceability.

Energy industry

Nuclear, thermal and wind power plants use automated systems to monitor turbines, boilers and generators. Robotic equipment using PAUT and TOFD techniques can detect internal defects with millimeter precision, optimizing plant shutdowns and extending the useful life of assets.

Case Study 2: In the energy field, Mistras Group and Eddyfi Technologies apply AI-based NDT 4.0 technology platforms and digital twins for monitoring pipelines, tanks and critical structures in power generation plants. These systems enable early defect detection, corrosion mapping and asset integrity optimization.

Aerospace and defense

In aerospace, NDT automation is vital to ensure flight safety. Collaborative robots inspect fuselages, wings and critical components for delaminations or micro-cracks. The use of digital twin technology and computer simulations makes it possible to evaluate structural behavior under different operating conditions.

Case Study 3: Stäubli Robotics and Arcadia Aerospace Industries are leaders in the adoption of robotic NDT and ultrasonic inspection automation systems. In the aerospace sector, they have managed to reduce inspection times of structural components by up to 60%, ensuring more consistent and safer results thanks to integration with Industry 4.0.

Advanced manufacturing

In metal and composite manufacturing, NDT automation ensures continuous quality and full traceability. Robotic inspection systems with AI verify defects during production, reducing part rejection and improving dimensional consistency. This drives efficiency under standards such as ISO 9001 and ISO 9712.

Case Study 4: A prime example is GE Aerospace and Siemens Energy, which have implemented robotic inspection systems equipped with artificial intelligence (AI) and computer vision to detect micro-defects during the manufacturing process of critical parts.

These systems integrate PAUT (Phased Array Ultrasonic Testing) and TOFD (Time of Flight Diffraction) techniques, allowing inspections to be performed without stopping the production line. The information is stored in real time and associated with the serial number of each component, ensuring full traceability under ISO 9001 and ISO 9712 standards.

The result has been a more than 35% reduction in part rejects and a 25% improvement in quality control efficiency, as well as a significant increase in dimensional and structural reliability.

This case demonstrates how the integration of Industry 4.0 and NDT automation in advanced manufacturing drives productivity, precision and sustainability in highly competitive environments.

Case Study 5: Eddyfi Technologies has driven the transformation of automated NDT through its Eddy Current Array (ECA) technology, designed for advanced inspection of pipes, welds and metal components in critical industries. This solution integrates smart sensors, robotic control and digital signal processing to detect surface defects with high resolution and repeatable accuracy.

Eddyfi’s ECA system enables inspections at speeds approaching 1 meter per second, significantly reducing equipment downtime and improving traceability of results. Its connectivity with cloud-based analysis platforms generates digital defect maps, enabling engineers to make faster and more informed decisions.

This case exemplifies the evolution towards NDT 4.0 technology, where robotics, artificial intelligence and predictive analytics converge to optimize asset integrity. Eddyfi’s implementation demonstrates how Industry 4.0 integration strengthens operational reliability and accelerates the transition to smart, connected inspections.

Watch the full interview with Eddyfi Technologies on Inspenet TV, where their specialists explain how Eddy Current Array (ECA) technology is revolutionizing NDT automation and flaw detection in pipelines and metallic structures.

Future prospects in Industry 4.0

Advances in Artificial Intelligence and deep learning

The development of Deep Learning algorithms will drive inspection systems capable of analyzing millions of signals simultaneously, identifying defects imperceptible to the human eye. This will reduce false positives and enable automated interpretation of NDT data, strengthening fault detection through AI.

At the same time, the combination of artificial intelligence with 5G networks will enable real-time monitoring of equipment and continuous communication between inspection systems and control platforms, enhancing the autonomy and accuracy of industrial processes.

New generations of sensors

Self-adjusting sensors, connected to the Industrial Internet of Things (IIoT) ecosystem, will offer more stable measurements and data processing in the cloud. Their integration with industrial SCADA and ERP platforms will enable full asset traceability, immediate deviation analysis and optimization of operational efficiency.

These sensors, supported by cloud computing, will facilitate collaboration between distributed systems, allowing data-driven decisions to be made from anywhere in the network.

Its direct connection with industrial SCADA and ERP platforms allows full traceability of processes and strengthens operational efficiency, as shown in the following figure.

Comprehensive predictive maintenance

The convergence of AI, Big Data and RBI (Risk Based Inspection) methodologies will consolidate a comprehensive predictive maintenance model, where repair or replacement decisions are based on condition, risk and criticality indicators.

This approach will reduce unscheduled downtime, optimize the use of resources and improve the profitability of industrial plants. The use of cloud-based analytical models and collaborative robotics in complex inspection tasks will enable safer and more efficient data collection and processing.

Industrial cybersecurity and digital resilience

As industrial systems become more interconnected, the protection of digital assets will be an essential pillar. Industrial Cybersecurity Strategies (ICS) will need to address the protection of IoT networks, cloud platforms and autonomous devices from emerging threats, ensuring information integrity and operational continuity.

In summary, the future outlook for Industry 4.0 points to a highly connected, automated and secure industrial environment, where the synergy between AI, IIoT, 5G, cloud computing and cybersecurity will transform the way critical assets are operated, inspected and maintained.

Conclusions

NDT automation and its evolution to NDT 4.0 are an essential pillar of industrial digital transformation. By integrating robotics, artificial intelligence and predictive analytics, organizations reduce costs, increase safety and improve operational reliability.

Adopting these technologies not only drives efficiency, but consolidates a new era of smart inspection, where the integration of Industry 4.0 enables more predictive, connected and sustainable asset integrity management.

“Integrate NDT 4.0 technologies into your inspection strategies to optimize the reliability and performance of your industrial assets.”

Share this article on LinkedIn or subscribe to Inspenet’s technical newsletter to stay up to date with innovations in the energy and industrial sector.

This article is part of the editorial line of Inspenet, official media partner of global events such as GASTECH, API, AMPP, ASNT, SLOM and others.

Frequently Asked Questions (FAQs)

What is NDT automation?

NDT automation consists of applying robotics, intelligent sensors and artificial intelligence algorithms to perform non-destructive testing (NDT) without manual intervention. Its objective is to increase accuracy, reduce human error and optimize industrial inspection times. It allows obtaining more accurate and consistent results, reducing the margin of human error and improving time and cost efficiency.

What does Industry 4.0 applied to NDT mean?

Industry 4.0 in NDT refers to the integration of digital technologies, such as the Industrial Internet of Things (IIoT), data analytics and cloud computing, within inspection processes. This enables connecting systems, automating decisions and enabling predictive maintenance strategies based on real-time data.

What is NDT 4.0 technology?

NDT 4.0 technology represents the digital evolution of non-destructive testing, combining AI, digital twins, robotics and machine learning. It aims to transform traditional inspection into a cognitive, connected and predictive system, where assets are continuously monitored to ensure their integrity and operational reliability.

Which sectors benefit most from NDT automation?

Primarily the energy, oil and gas, aerospace, advanced manufacturing and defense sectors, where automated inspection increases safety, traceability and operational reliability.

How does AI contribute to automated non-destructive testing?

Artificial intelligence (AI) analyzes real-time data, identifies patterns and predicts potential failures, improving maintenance planning and strengthening risk-based inspection (RBI).