Introduction

Compressors in gas flaring play a very important role in a variety of industrial applications involving the handling and transfer of gases. However, its effectiveness is only achieved when the technology is properly selected and applied in the relevant contexts. It is important that the operator clearly defines the application and specifies the requirements of the product transfer process.

Once the operating parameters are established, the application engineer will be able to determine if a compressor is the appropriate technology to meet the specific needs of the process.

What is a gas compressor?

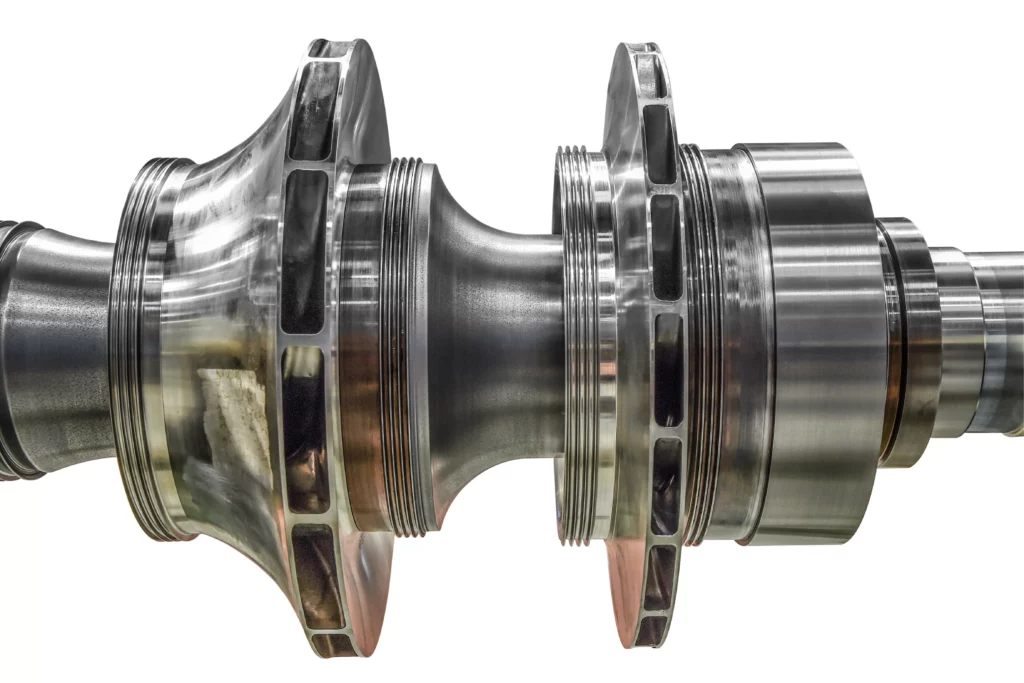

A compressor is a mechanical device designed to increase the pressure and reduce the volume of a fluid, a gas, through the use of cylinders, pistons, rotors or impellers. The energy for its operation can come from an electric motor, a gas turbine or an internal combustion engine.

Compressors can come in a variety of types and configurations, adapting to specific application needs and design requirements. Common types of compressors used in natural gas processing include reciprocating, centrifugal, axial and screw compressors.

A compressor plays a critical role in natural gas processing by enabling the gas to move through pipelines, valves, separators, filters and other equipment at the proper pressure and flow rate.

It also contributes to maintaining optimal operating conditions in gas processing plants, where gas treatment and conditioning is carried out to meet quality, safety and environmental performance requirements. In addition, the use of a compressor can increase recovery and efficiency of natural gas production in reservoirs by injecting compressed gas into wells to stimulate hydrocarbon flow and pressure.

Compressors in gas flaring

Compressors in gas flaring bring several benefits to natural gas processing, such as improving transportation and storage by reducing the volume and increasing the density of the gas. This makes it possible to transport a larger quantity of gas through pipes of the same diameter and store it with the same capacity in the tanks.

They also help raise the quality and value of natural gas by removing unwanted components such as water, carbon dioxide, hydrogen sulfide and other contaminants. In addition, the compressors optimize energy efficiency and profitability of natural gas processing by reducing energy losses and operating costs associated with low-pressure, low-flow gas streams, and by increasing production and revenues from gas sales and by-products.

Compressors can pose challenges in natural gas processing, including high capital investments and maintenance costs. These aspects are due to the complexity and cost associated with compressors, which require periodic inspection, repair and replacement of parts and components.

In addition, compressors in gas flaring consume a significant portion of the energy generated by gas processing plants or fuel supplied by gas producers, resulting in greenhouse gas emissions to the atmosphere.

Technical and operational problems arise, such as surges, vibrations, noise, leaks, fouling, erosion and wear, which can affect compressor performance and reliability, resulting in downtime, damage and safety hazards.

Importance of compressors in the fuel gas flaring process: Technical rationale

Compressors are fundamental elements in the fuel gas combustion process for a variety of technical reasons:

- Increased gas pressure: Compressors in gas flaring reduce the volume of gases, increasing their pressure and facilitating their transport through pipelines to their final destination.

- Maintaining gas flow: As gases move along pipelines, they experience friction and pressure loss due to elevation differences. Compressors counteract these losses by providing the additional pressure needed to maintain a continuous flow of gas.

- Temperature control: The compression of gases generates heat, so it is necessary to dissipate this excess temperature to avoid safety problems and ensure that the gas is at an optimum temperature for further combustion or processing.

- Energy efficiency: Multi-stage compressors, which include inter-stage cooling, reduce the volume of gas between each stage and the amount of energy required for the next compression. This design improves the energy efficiency of the process.

- Safety: Compressed gas represents a form of potential energy that must be handled with caution, it is necessary to ensure proper design and assembly to prevent possible risks such as fire or explosion.

- Combustion facilitation: Efficient combustion of fuel gases often requires them to be at a higher pressure. Compressors in gas flaring fulfill this role, increasing gas pressure to levels suitable for various combustion processes in applications such as power generation or industrial heating.

How does natural gas compression work?

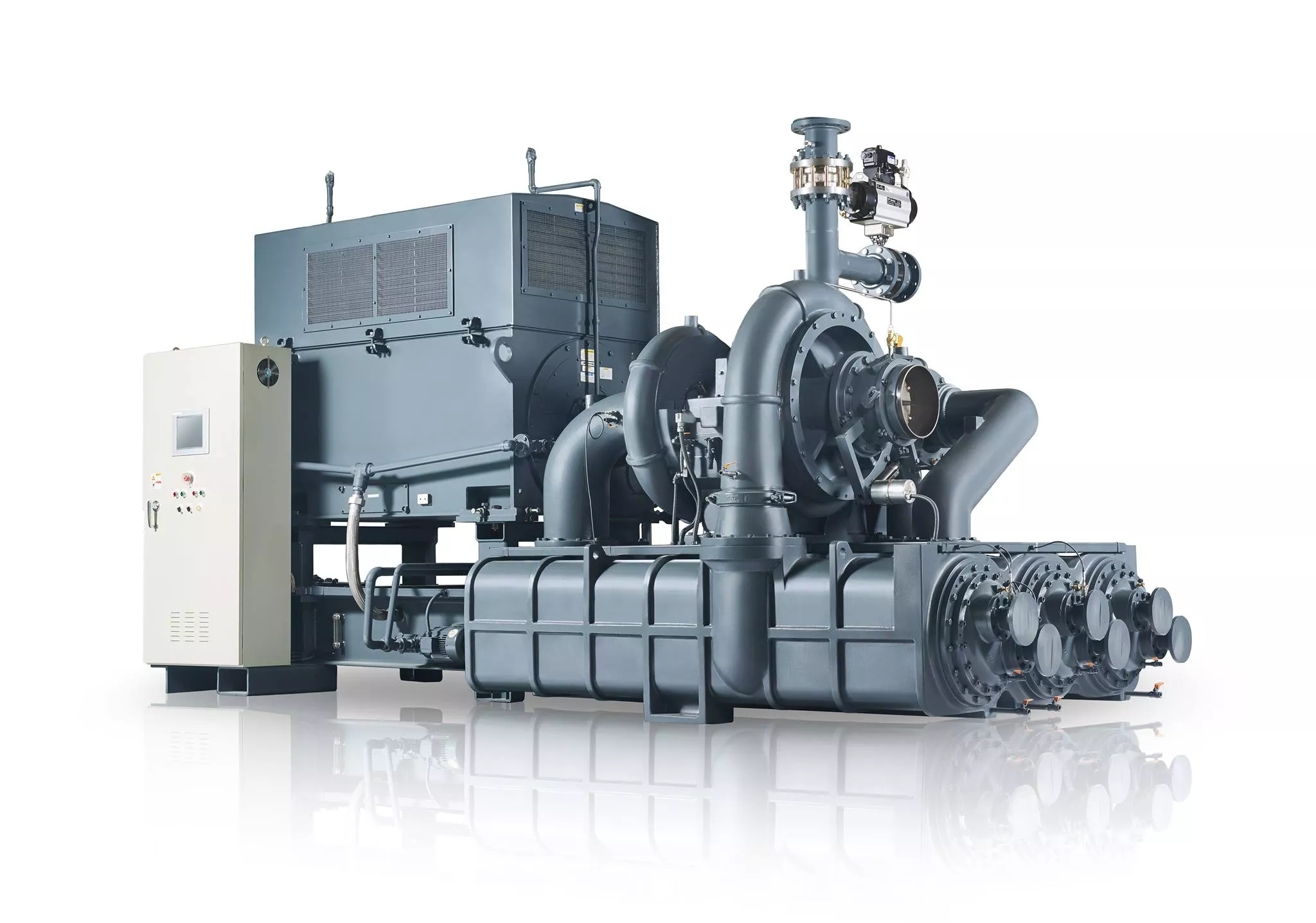

Compression of natural gas is typically performed at facilities such as gas processing plants or compressor stations, located along the pipeline network. At these sites, large engines and compressors are used to increase the pressure of the natural gas before it is introduced into the pipeline system. This pressure increase facilitates the continuous flow of gas through the pipelines and ensures its efficient and safe transport.

The efficiency of natural gas compression is determined by several factors, including the characteristics of the compressors used, both in terms of size and power, as well as the time required to perform the compression. Generally speaking, larger capacity compressors tend to be more efficient than smaller compressors because they can handle larger volumes of natural gas at higher pressures in shorter time intervals.

There are three main applications based on product transfer that fit into the compressor sweet spot. Among which we can mention:

- Vapor recovery: This process involves the capture of residual gases remaining in storage vessels, which, in the past, could have been released into the atmosphere. Today, due to stricter environmental and safety regulations, as well as their economic value, these gases must be recovered. Vapor recovery is typically applied to liquefied gas vapors remaining in vessels after transfer, natural gas vapors in storage tanks, sulfur hexafluoride in electrical transformers, compressor seal leaks in larger processing plants, and in the emptying of storage vessels prior to maintenance, reconditioning or replacement.

- Pressure boosting: In this process, a gas is moved from one location to another by increasing its pressure to a level that allows it to be sent to another location or process from the storage tank at a higher pressure. For example, a nitrogen booster system raises the pressure of stored nitrogen gas to 125 pounds per square inch (psig) (8.6 barg) at an increased pressure of 300 psig (20.6 barg) to meet process demands.

- Also, pressure boosting is used to transfer refined natural gas from a low-pressure distribution line to a storage tank that feeds a burner in a heat-treatment process. Compressors are ideal in this process because of their ability to handle a wide range of pressure boosting conditions.

Reduction of flaring emissions

Gas flaring, which involves the controlled combustion of natural gas released during oil and gas production, is a common practice in the industry to dispose of excess or waste gases that cannot be economically utilized. This action is relevant in the context of gas compressors for several reasons:

- Environmental impact: Gas flaring releases greenhouse gases and other pollutants into the atmosphere, contributing to climate change and air pollution. Therefore, minimizing gas flaring is crucial for environmental conservation.

- Energy waste: Gas flaring represents a significant waste of energy resources, since the natural gas flared could be used for power generation, heating or other productive uses.

- Regulatory compliance: Many regions have regulations to limit or reduce gas flaring due to its environmental impact. Compliance with these regulations is essential for oil and gas companies, and reducing flaring often requires the implementation of alternative gas management practices.

Conclusions

The importance of compressors in the combustion of fuel gases is significant in the modern energy industry. These devices play a key role in facilitating the efficient and safe transport of fuel gases, such as natural gas, from production to consumption points. Compression of these gases not only allows them to be stored safely and economically, but also distributes them over long distances through pipeline networks.

Increased gas pressure ensures more efficient and complete combustion, thus maximizing the utilization of these energy resources and reducing harmful emissions to the environment. They are fundamental components in the responsible and sustainable use of fuel gases, contributing significantly to energy security and economic development.

References

1. www.pumpsandsystems.com/compressor

2. https://extension.psu.edu/understanding-natural-gas-compressor-stations

3. https://www.archrock.com/what-is-natural-gas-compression/