During the LatinCORR conference in Panama, Rockwool showed its commitment to industrial protection, with Ricky Seto, Technical Services Manager, as spokesman, explaining how the company combines research and international standards in its products. The world-renowned company uses mineral wool as a base for industrial insulation, positioning itself as a reference in the energy and industrial sector.

The Rockwool technologies presented during the event were WR-TECH and CR-TECH, the former being a hydrophobic treatment that is integrated into mineral wool insulation and acts as a first line of defense against moisture, repelling water and preventing it from penetrating the insulation system and thus reaching metal surfaces.

CR-TECH, on the other hand, complements this protection with a direct action on the target, since if water manages to pass through the insulation barrier, it activates and deposits an inhibiting film on the metal surface, protecting it from corrosion. In short, while WR-TECH prevents water from reaching the metal, CR-TECH mitigates the damage should this happen.

Although the two technologies work together, they have different functions, being the very nature of the mineral wool that guarantees the insulating performance.

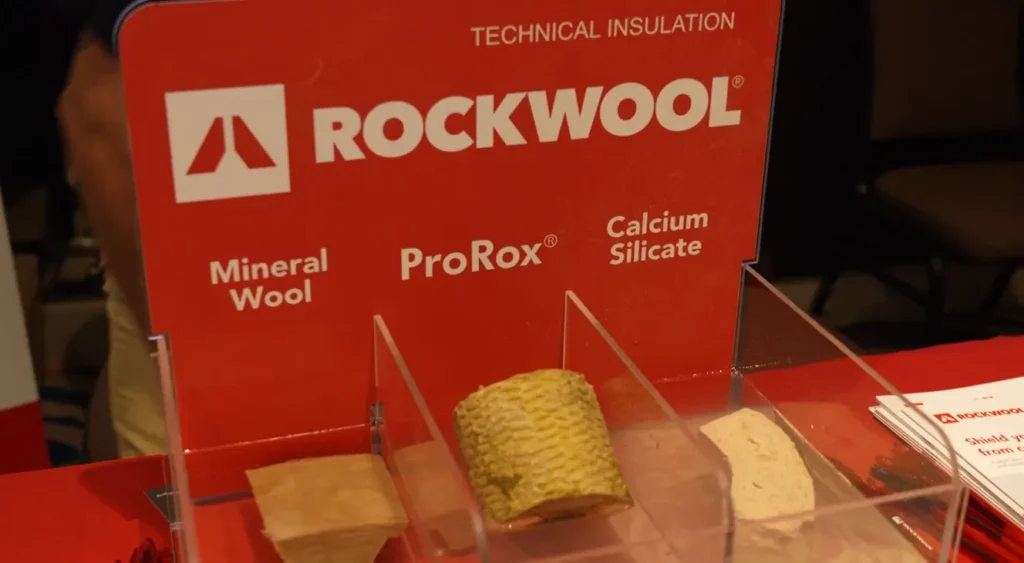

The basis of the company's products is mineral wool, specifically rock wool, a non-combustible material that offers high resistance to extreme temperatures, an intrinsic property that prevents the spread of fires and protects structures by keeping temperatures low, even in conditions of intense fire.

In this context, company's ProRox range is specially designed to bring these qualities to the industrial environment, with insulation solutions for pipes, tanks and equipment operating at high temperatures. Thanks to their rockwool composition, ProRox products not only improve thermal efficiency, but also contribute to passive fire protection in industrial installations.

Rockwool also take sustainability into consideration in the manufacture of their products, and Ricky Seto underlined this by commenting that the mineral wool used is indefinitely recyclable. During the manufacturing process, any waste or material that does not meet specifications is returned to the melting furnace to be turned back into insulation.

In addition, the use of mineral wool insulation in industrial installations contributes directly to decarbonization and energy efficiency objectives, since by reducing thermal losses in pipes and industrial equipment, the energy consumption required to maintain operating temperatures is minimized, thus reducing the associated carbon emissions.

The company estimates that its solutions save up to 10 times more carbon emissions than those generated during manufacturing, a relevant fact for industries seeking to reduce their environmental footprint.

The company actively participates in the improvement of international standards as a member of ASTM and ENISO, contributing to the development and updating of standards, translating the real needs of industrial users and applicators into global regulatory frameworks. This participation ensures that Rockwool products, in addition to meeting current requirements, also anticipate future demands in terms of quality and safety, reinforcing its position in the global industrial insulation market.

The commitment of Rockwool s commitment to technical excellence is reflected in the development of technologies such as WR-TECH and CR-TECH, which offer comprehensive protection in demanding industrial and marine environments. Added to this is the flame retardant resistance offered by the mineral wool in its products and a strong focus on sustainability, thanks to efficient recycling processes and the contribution to reducing carbon emissions. This is how the company demonstrates why it is considered one of the leading companies in industrial insulation, combining technology, safety and respect for the environment in every solution it offers.

For more content about LatinCORR 2025, please visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.