In a recent interview at AMPP 2025, Jason Menchaca, NobelClad’s Territory Manager for the Southwest and Western U.S., discussed how DetaClad Technologies, based on explosion welding, is transforming the way industrial equipment is designed and built in critical sectors such as energy, petrochemical and natural gas.

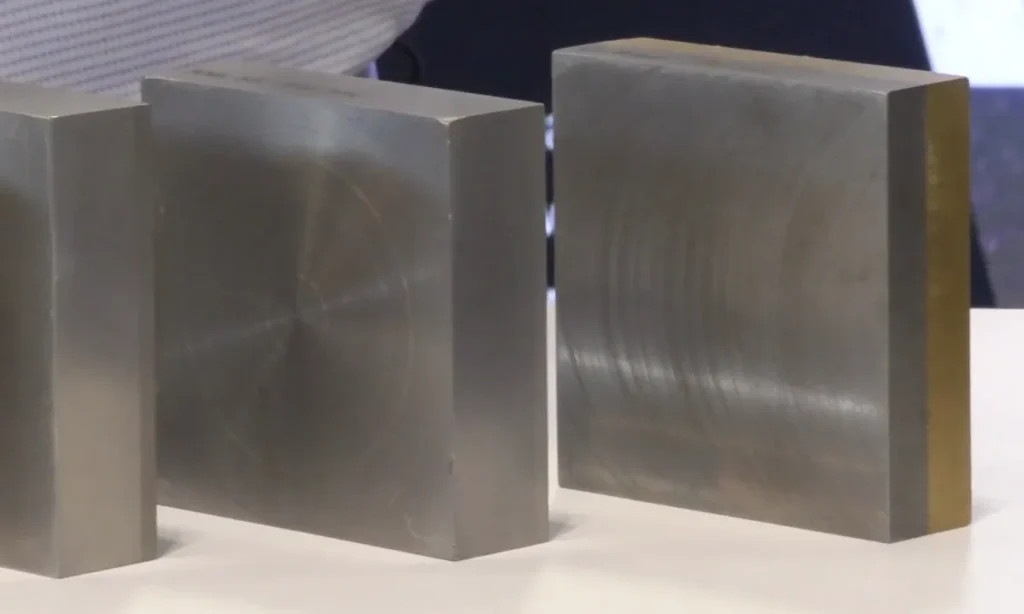

Unlike other technologies, DetaClad allows dissimilar metals to be joined without compromising their original chemical and mechanical properties. This is key in extreme environments, where corrosion resistance and structural reliability are non-negotiable.

DetaClad's technical advantage over conventional technologies lies in the fact that the metals retain their structure and performance after the joining process. This is not the case with methods that alter the composition or reduce the material's lifespan. Furthermore, NobelClad applies international standards such as ASME and ASTM, along with customer specifications, to ensure consistent results in clad plates and manufactured components.

Menchaca also discussed another of NobelClad's developments, Cylindra, a specialized solution for cryogenic applications, specifically in stainless steel-to-aluminum transitions. This five-layer component facilitates the passage of fluids at high pressure and temperature within liquefied natural gas (LNG) systems.

Cylindra is currently gaining ground in the energy sector thanks to its reliability and adaptability to the demanding requirements of LNG, a growing market driven by the global energy transition.

The process is based on the customer's needs: pressure, temperature, and type of fluid being processed. Based on this data, NobelClad's engineering team analyzes whether the requested combination is technically and functionally feasible.

The company offers both standard combinations and custom configurations, significantly expanding the range of solutions available for complex industrial environments.

Although DetaClad has been developed and refined for over six decades, its application is constantly evolving. Events like AMPP allow NobelClad to interact with end users and identify new challenges where its technology can make a difference.

From explosion welding for industrial equipment to specific solutions for cryogenic environments, NobelClad demonstrates that innovation doesn't depend on the age of the technology, but on its ability to adapt to new market demands.

For more AMPP 2025 content, visit our YouTube channel and LinkedIn profile.

Source: Inspenet.