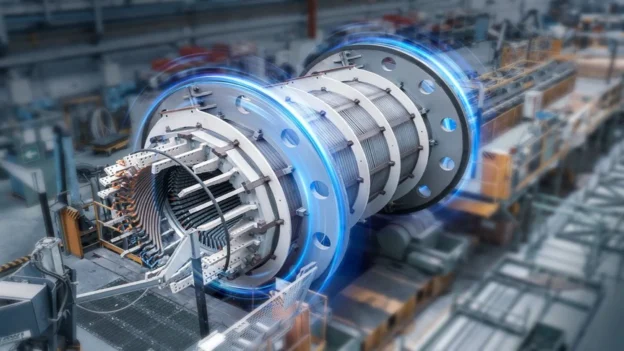

When it comes to innovative projects aimed at solving the current energy crisis, one initiative that could transform large power plants, characterized by their high dependence on gas and high carbon emissions, is the GT36 turbine.

How does the GT36 turbine work?

The GT36 turbine, developed by Ansaldo Energía, a leading energy services engineering company, is part of the FLEX4H2 (Flexibility for Hydrogen) project, in collaboration with the EU and Switzerland. The objective of this project is to finance and develop technologies to replace fossil fuels. fossil fuels using existing infrastructure and, ideally, offering improvements in performance.

The GT36 turbine is distinguished by its ability to operate with a mixture of natural gas and pure hydrogen. It uses a constant pressure sequential combustion system (CPSC) that allows working with various proportions of these fuels, including up to 100% hydrogen. hydrogen .

The turbine also employs two flame stabilization systems: one aerodynamic and the other by self-ignition. High-pressure tests have demonstrated its flexibility to include between 0 and 100% hydrogen, thanks to modifications in the combustion chamber.

Federico Bonzani, Ansaldo Energia’s Product and Technology Director, claims that a single “superturbine” equipped with the FLEX4H2 system can eliminate up to 2,000,000 tons of carbon annually. In addition, one turbine of this type can power more than 500,000 homes.

Advances of the GT36 turbine. Source: Ansaldo Energy.

Successful tests

The tests were carried out in Cologne, Germany, where the turbine demonstrated its ability to operate with different proportions of hydrogen and natural gas, adapting to the needs. This technological breakthrough is crucial for the decarbonization of the decarbonization of the energy sector opening up new possibilities for sustainability.

Notably, Ansaldo Energy’s first H-class gas superturbine, which took four years to develop, has proven its operation with both pure hydrogen and combined with natural gas in various proportions. However, prior to commercialization, further system testing and optimizations are required.

However, future research will focus on stabilizing the turbine system to changes in the flame due to modifications in the fuels and their position in the combustion stages. The objective is to adjust fuel equivalence and injection ratios to avoid disparities that affect ignition timing or normal operation.

Follow us on social networks and don’t miss any of our publications!

YouTube LinkedIn Facebook Instagram X

Source: ecoticias

Photo: Ansaldo Energía