Inspenet, May 24, 2023

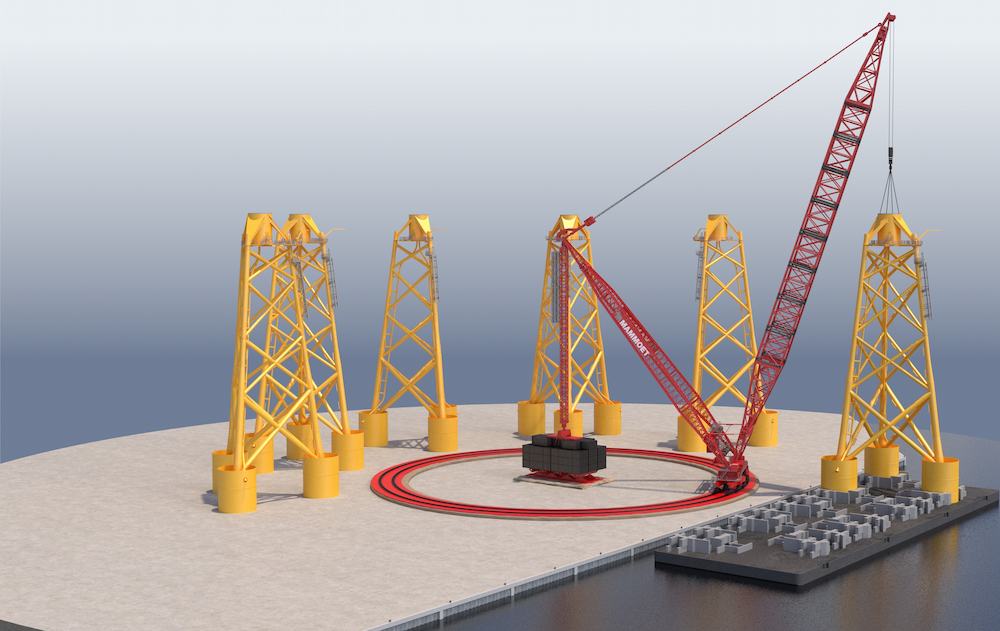

Mammoet , a Dutch company specialized in lifting and transporting large structures, has started construction of the SK6000, an additional 6,000 t capacity ring crane to serve growing energy markets.

The first parts for the new 6,000 t ring crane will be delivered shortly to the Mammoet engineering powerhouse in the Netherlands. In the coming months, manufacturing and production will continue as it prepares for its first project, scheduled for delivery in 2024.

It becomes the world’s largest capacity land crane and can run entirely on electric power, allowing customers to execute projects sustainably.

The introduction of this 6,000 t ring crane sets a new standard in global heavy-lift capacity, enabling customers to build heavier and larger components than ever before. With its unmatched reach, hook height and lifting capacity, it offers a zero carbon lifting solution that others simply can’t match.

The new SK6000 ring crane shares the same engineering DNA as its predecessor, the SK350. By employing similar design principles and lifting techniques, it offers customers continuity and peace of mind. Much crane technology has been working successfully – and safely – on construction sites around the world for many years.

The Mammoet SK6000: an essential tool for wind power projects and offshore production

Like previous models, the SK6000 is shipped in containers, allowing for rapid mobilization and assembly on site, providing ultra-heavy lifting capacity where it is needed.

It has been designed with the next generation of offshore wind farms in mind and will serve all global energy markets where additional lifting capacity is needed, both onshore and offshore.

As offshore wind components grow in scale and weight, more lifting capacity is needed. The SK6000 offers this capability and solves an important design limitation. Mammoet’s latest innovation will allow customers to integrate taller and larger turbines, and launch heavier foundations, whether fixed or floating.

Mammoet SK6000 reduces downtime during component removal and installation in refineries

In the conventional power sector, the SK6000 enables offshore and floating production projects to reduce integration time by building even larger top modules. Onshore, it helps refineries reduce downtime by removing and installing larger components with minimal disruption.

Source : https://www.mammoet.com/news/worlds-largest-electric-crane-now-being-built/

Illustrations : Mammoet

Don’t miss the Inspenet News at: https://inspenet.com/inspenet-tv/