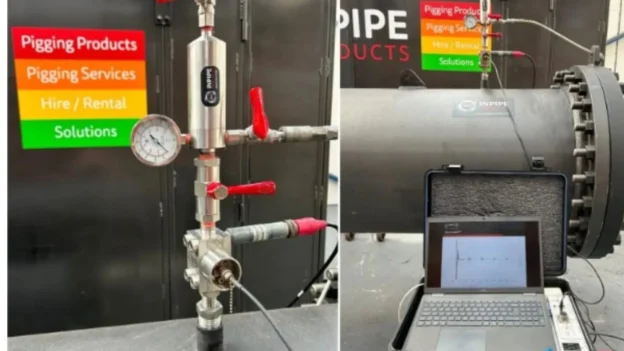

North Yorkshire-based iNPIPE PRODUCTS this month introduced a new product for detecting leaks and blockages in pipelines. Using acoustic reflectometry technology, this new device, called Acoustek, is able to identify blockages, obstructions and leaks accurately.

Acoustic reflectometry for leaks and blockages in pipelines

Acoustek distinguishes itself as the first product on the market to employ reflectometry, i.e. the use of wave and pulse reflections, to detect anomalies in pipelines. This technology not only identifies blockages and leaks, but also evaluates the speed and opening capacity of the valves, providing a comprehensive analysis of the system.

Simon Bell, Managing Director of iNPIPE PRODUCTS explained that Acoustek represents a significant change in the offshore industry. According to Bell, this tool allows operators to almost completely eliminate the costs and risks associated with blockage and leak detection and valve performance with older technologies. In addition, he noted that Acoustek provides accurate and detailed acoustic data in a short time, allowing any anomaly to be located without risk to personnel or equipment, and without the need for costly support services such as ROVs, or interruptions to normal operations. or disruptions to normal operations.

Acoustek performance and efficiency

The Acoustek system connects directly to an active pipeline and sends an acoustic pulse through it. By measuring the reflected pulse, it can detect changes in the inside diameter of the pipe and assess the condition of valves, including partially open or closed valves. This system offers 100% accuracy in verifying the closing efficiency of emergency valves and can detect and locate reductions in pipe diameter at distances up to 10 km from the point of installation.

In addition, Acoustek is designed for complex pipeline networks and provides continuous monitoring capabilities with remote inspection. Its easy integration with existing pipeline equipment, requiring installation at only one end and its ability to locate blockages or obstructions up to 10 km away, make it an efficient and practical solution.

Recently, Acoustek was deployed on a North Sea platform to validate the performance standards of a gas import/export subsea isolation valve (SSIV). This valve was to close in 60 seconds and was located at a depth of 136 meters and 338 meters along the pipeline. Using the acoustic data generated by Acoustek, the performance of the SSIV was successfully measured in a single shift, confirming its efficiency according to the required standards.

Follow us on social networks and don’t miss any of our publications!

YouTube LinkedIn Facebook Instagram X

Source and photo: inpipeproducts