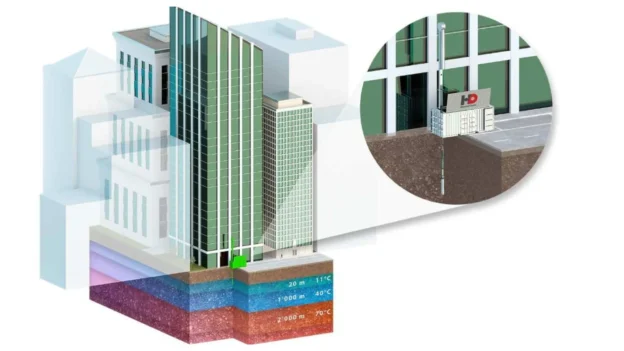

HammerDrum has developed a drilling robot, a technology that will aid in deep geothermal drilling. deep geothermal drilling and promises to significantly change the way such work is carried out in urban areas.

This new technology reduces the size of the construction site by a factor of 100 compared to traditional drilling rigs, allowing for deep drilling in areas where space is limited.

Cost savings and automation of the drilling robot

In addition to being more compact, HammerDrum technology is significantly more cost-effective. Thanks to the simplification of the process and the high level of automation, deep drilling costs are reduced by 80%. This represents a significant advance in terms of efficiency and savings for geothermal energy projects. geothermal energy projects .

The drilling machine developed by HammerDrum is innovative and efficient. It is placed directly in the borehole and contains all the technologies necessary to perform fully automatic drilling. Unlike traditional methods, which are controlled from the surface, this compact machine allows automated work in confined spaces, which is ideal for urban environments.

Compact and efficient technology

The 6-meter-long electric drill is lowered into the well by means of a steel cable. Once at the bottom, it locks with a clamp and uses an innovative rotation mechanism to drill predefined sections. Cuttings are collected during drilling and returned to the surface at the completion of each process, allowing immediate preparation of the drill for the next operation.

This is how HammerDrum technology works. Source: HammerDrum AG.

To minimize downtime, a second machine can be put into the well immediately. In the simulations, the drill achieves an up and down speed of approximately 15 km/h and a drilling rate of about 5 cm per minute. This makes it possible to complete a 1 km well in a period of 3 to 4 weeks.

Surface handling is also automated and can be performed in a small space, equivalent to two parking spaces. This makes drilling continuous and efficient, similar to the operation of a robot mower, providing an ideal solution for projects in densely populated urban areas.

Follow us on social networks and don’t miss any of our publications!

YouTube LinkedIn Facebook Instagram X

Source and photo: hammerdrum