In a collaboration between earth4Earth(e4E) and Sustainable Ventures, the first wall made entirely of carbon negative bricks has been installed in the UK.

The dimensions of the wall, 4×4 meters, was christened“Wonderwall“, and is located in the Sustainable Ventures offices within the Sister Renold building on the University of Manchester’s renovated North Campus.

Carbon sequestration through negative carbon bricks

The 1200 bricks used in the construction were developed by e4E from recycled excavated soil and a specialized lime-based binder that does not require high temperatures for production.

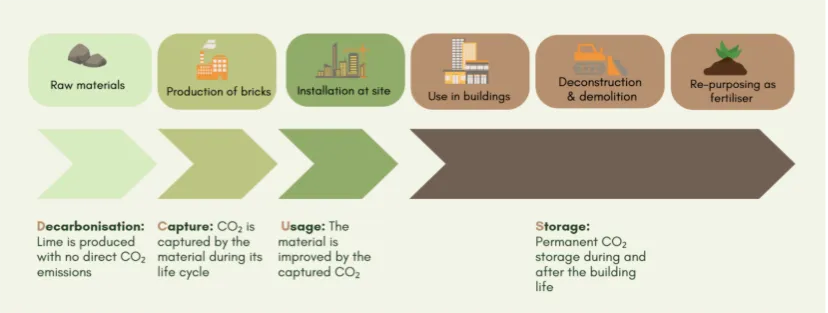

By implementing technology called DCUS (Carbon Decarbonization, Capture, Utilization and Storage), each brick has a capacity to absorb up to approximately 0.178 kg of CO2 from the air. Overall, the wall retains about 213.6 kg of CO2, an amount equivalent to the carbon footprint generated by brewing about 760 cups of coffee.

This process of e4E bricks are manufactured at room temperature, eliminating the use of high temperature kilns and reducing associated emissions. bricks are made at room temperature, eliminating the use of high-temperature kilns and reducing associated emissions. In addition to capturing CO2 throughout their life cycle, the

The wall will now permanently capture and store CO2, acting as a carbon sink.

Lei Zhang, co-founder of e4E.

The version of the brick used in this project, the N10 model, contains 10% of the special e4E binder. These bricks have received a third-party verified

The Sister Renold building, which houses the Wonderwall, is part of an urban development supported by Barclays and the Greater Manchester Combined Authority. Sustainable Ventures ‘ new offices aspire to become a hub for climate tech startups .

This space is also intended to host more than 100 companies so that they can receive advice, workspace and financing to accelerate their impact on the transition to renewable and sustainable energy.

Founded in Sheffield in 2023, earth4Earth is inspired by the traditional Chinese buildings known as Tulou, made of rammed earth. With manufacturing plants in Wuhan and a team spread across China and the UK, the company is committed to affordable, sustainable and ethically produced materials.

Its co-founder, Professor Yi Luo, has dedicated her career to researching these forms of sustainable architecture, integrating this ancient knowledge with technological innovation for the 21st century.

Source and photo: earth4Earth