Upstream, Midstream and Downstream: Stages and operations in oil & gas

Midstream is the operational hub that connects Upstream and Downstream in the oil and gas industry.

Mechanical Engineer with experience in the oil and gas sector, has technical skills in static equipment inspection, project control, development of work scopes and quality assurance. Contributes to the exchange of knowledge and best practices by writing technical articles related to the energy sector.

Midstream is the operational hub that connects Upstream and Downstream in the oil and gas industry.

Tanks with internal floating roofs reduce emissions, preserve product, and improve storage reliability.

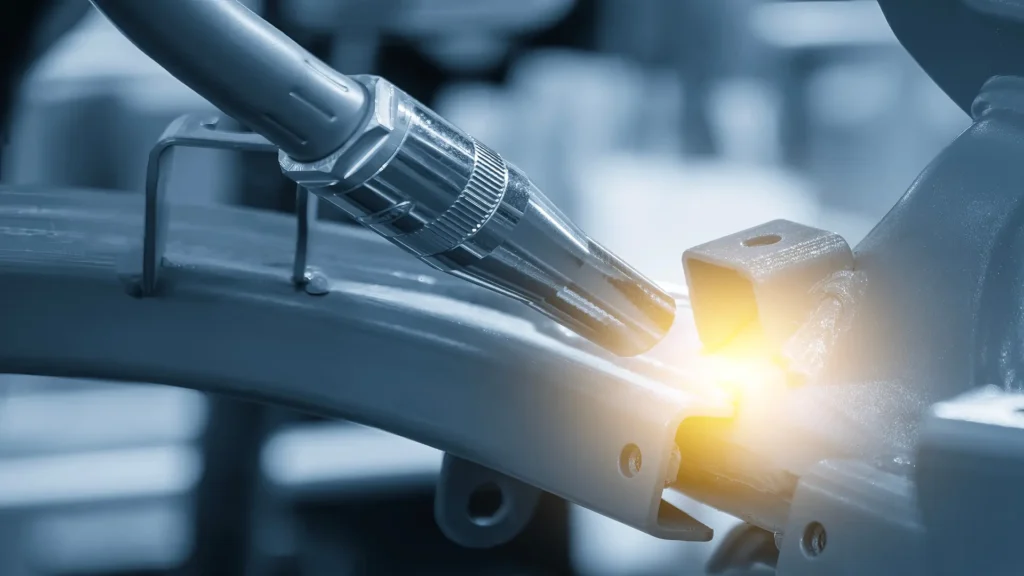

This guide to TIG welding aluminum offers an industrial approach to understanding the material, making adjustments, and reducing defects.

ASME Section IX governs welding in pressure vessels, ensuring technical qualification, document traceability, and BPVC compliance during industrial fabrication.

GD&T certification aligns design, quality, and production, reducing dimensional conflicts through consistent application of ASME Y14.5.

Oil terminals are structures necessary for storing, transferring, and controlling hydrocarbons, ensuring logistical continuity, operational safety, and industrial integrity.

In industrial sectors where an undetected signal can trigger failures or shutdowns with a high economic impact, relying exclusively on the human “pulse” introduces a variability that modern…

Visual inspection under ASME PCC-3 strengthens the risk-based approach by linking CoF, PoF, and visual data with reliable decisions.

CALM monobuoys must be adapted to alternative fuels, integrating cryogenics, advanced materials, and monitoring to ensure safe transfer.

The new generation of marine hoses combines advanced materials and digital monitoring to ensure safer, more reliable, and sustainable offshore transfers.

In-service visual inspection provides real evidence to assess external conditions, anticipate failures, and optimize risk-based industrial integrity programs.

Floating roof seals control vapors, reduce emissions and evaporation losses, improve operational safety, and maintain the mechanical stability of the roof.