Condition-based monitoring of critical assets

Condition-based monitoring transforms operational data into predictive decisions, increasing the reliability and safety of critical assets.

Condition-based monitoring transforms operational data into predictive decisions, increasing the reliability and safety of critical assets.

PAUT allows weld defects to be identified with high resolution, speed, and digital traceability, optimizing mechanical integrity in industry.

Operators guarantee safety, continuity, and efficiency in every port operation, becoming the cornerstone of operational excellence.

Pipeline welding combines technology, control, and precision to ensure industrial integrity and reliability.

The ISPS Code strengthens maritime security and maritime cyber security, protecting ships and ports in accordance with the SOLAS Convention.

ISO 9712 certifies competencies in eddy currents, key to mechanical integrity and industrial safety.

LNG is now a key component of global energy security and sustainability. Inspenet explains why it is leading the energy transition.

Heat exchangers, classified as pressure vessels, require advanced NDT inspection to ensure safety, mechanical integrity and thermal efficiency in industrial operations.

Structural integrity ensures safety, optimizes assets and prolongs service life in the industry.

Learn how the thermal oxidizer optimizes the treatment of industrial gases and ensures the efficient control of pollutant emissions. .

Key types, functions and API standards for oil storage tanks in safe and regulated industrial operations.

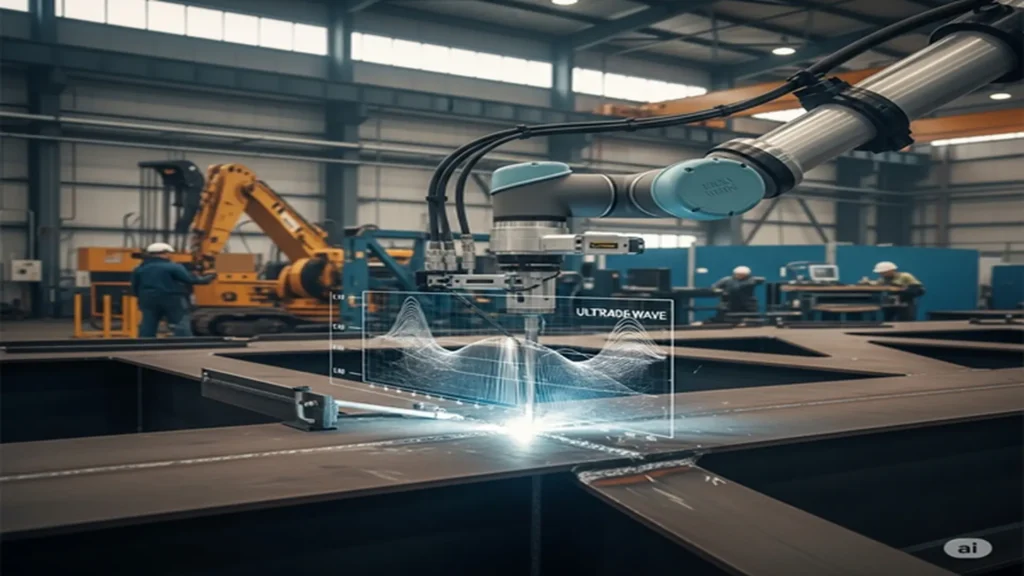

Artificial intelligence generates benefits in ultrasonic weld inspection by redefining its accuracy standards in the industry.