Subsea oil and gas exploration, also known as offshore exploration, is a crucial process in the global energy industry. This process focuses on the search, evaluation, and extraction of hydrocarbon reservoirs that lie beneath the ocean floor.

The complexity and technical challenge of subsea exploration lies in the need to operate in deep and diverse marine environments, where potential oil and gas reservoirs that are crucial to meet the world’s energy demand are located.

Key aspects of the subsea oil and gas exploration sector

Prospecting in the offshore sector involves the use of advanced technologies such as 3D and 4D seismic to obtain detailed images of the sub-seabed. These images allow accurate mapping of potential hydrocarbon reservoirs.

Exploratory drilling consists of the creation of test wells, known as exploratory wells, which are drilled to confirm the presence and commercial viability of hydrocarbons in the reservoirs previously identified through seismic prospecting. Once the viability of the reservoirs has been confirmed, specialized infrastructure is established for extraction, including the installation of fixed or floating production platforms, as well as offshore gathering and processing systems.

Extracted hydrocarbons are transported from offshore platforms to onshore facilities via subsea pipelines or tankers. Subsea pipelines provide a continuous and safe means of transportation, while tankers offer flexibility in the logistics of distributing the extracted resources.

This comprehensive process, from exploration to transportation, requires rigorous coordination and the use of state-of-the-art technologies to ensure efficiency, safety, and sustainability in the exploitation of subsea oil and gas resources.

Technologies used in subsea hydrocarbon exploration

Several advanced technologies are used in subsea hydrocarbon exploration to perform key tasks such as reservoir detection, drilling, and extraction. Some of the most important technologies include:

- Underwater seismic: Uses specialized equipment to send sound waves to the seafloor and record their echoes, providing detailed images of subsurface geological structures and helping to identify potential oil and gas deposits.

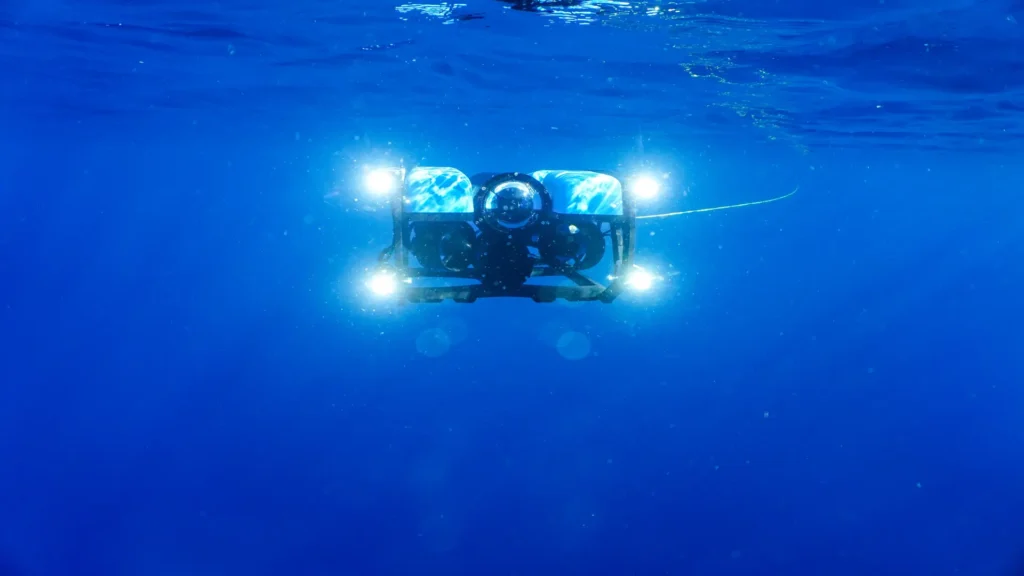

- ROVs (Remote Operated Vehicles): These remotely operated vehicles are essential for inspecting and working in marine depths that are inaccessible to humans. ROVs are equipped with cameras, manipulation tools, and sensors to perform various underwater tasks.

- Subsea drilling platforms: These are floating or semi-submersible structures that house drilling equipment and allow drilling subsea wells at great depths. These platforms are important for offshore hydrocarbon extraction.

- Subsea monitoring and control technology: Includes advanced systems to monitor pressure, temperature and other parameters in subsea wells. This ensures operational safety and optimizes hydrocarbon production.

- Subsea production technology: Involves specialized subsea equipment such as subsea Christmas trees, water and gas separation systems, and subsea pipelines. These components are essential for the efficient and safe extraction of oil and gas from subsea reservoirs.

These combined technologies enable the energy industry to explore, evaluate and develop subsea reservoirs efficiently and safely, playing a key role in meeting global energy demand.

Characteristics of underwater technologies

The following are characteristics of these technologies

Remotely Operated Vehicles (ROV)

Unmanned underwater robots, also known as remotely operated vehicles (ROVs), are equipped with cameras, advanced sensors, and mechanized arms. These devices are designed to perform inspection, maintenance, and repair of underwater equipment. Thanks to their sophisticated technology, ROVs can operate at depths beyond human limits, reaching up to 6,000 meters. These capabilities enable underwater robots to carry out work in extreme and hard-to-reach environments, providing an efficient and safe solution for underwater exploration and maintenance in the offshore oil and gas industry.

2. Autonomous Underwater Vehicles (AUVs)

- Description: self-propelled and programmable robots.

- Functions: perform seabed mapping and environmental surveys.

- Operation: can operate for long periods without direct human intervention.

3. Floating production systems (FPSO, Floating Production, Storage, and Offloading)

What are FPSOs (Floating Production, Storage, and Offloading)?

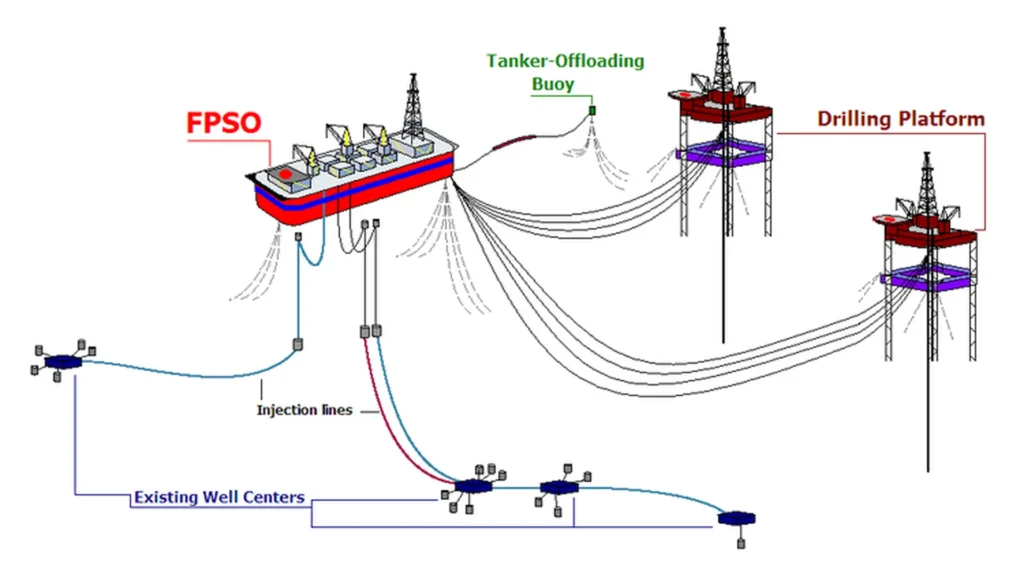

FPSOs (Floating Production, Storage, and Offloading) are floating units, generally based on the hull of a converted oil tanker. These facilities are equipped with advanced hydrocarbon processing systems for the separation and treatment of crude oil, water, and gases that are transported on board from subsea wells through flexible pipelines. FPSOs enable the efficient production, storage, and offloading of hydrocarbons, facilitating the exploitation of resources in remote and deepwater locations.

FPSO units are designed to remain at sea for long periods. Similar in appearance to large tankers, these vessels are used for oil and gas production, processing crude oil and natural gas extracted from nearby offshore platforms or subsea installations. In addition, they have large storage capacities for the processed hydrocarbons. Through these vessels, stored oil is unloaded and transferred to tanker trucks for transportation.

4. Subsea production systems

The subsea production system consists of a series of interconnected components that operate together to extract and process hydrocarbons from the offshore well to surface facilities. This system includes a group of wellheads, mounted on a common template, from which production from each wellhead is routed through a common manifold, pipeline, and riser. This assembly transports the hydrocarbons to a surface facility.

The system has a common control distribution network that supplies power, signals, and communications necessary for the operation and monitoring of the equipment. Major components of this system include subsea drilling systems, subsea christmas trees, wellhead systems, manifolds, subsea bridging units, riser, tie-in and flowline systems, and control and instrumentation systems. These subsea facilities are critical to the installation and maintenance of these components, ensuring continuous and efficient operation in the marine environment.

5. 4D seismic imaging

4D seismic imaging represents an advanced form of 3D seismic that adds time as a fourth dimension. This technology allows monitoring reservoir changes over time, providing data for hydrocarbon production management and optimization. Data transmission from downhole to surface is achieved through several methods:

- Mud pulse telemetry: Uses pressure fluctuations in the drilling fluid column to encode and transmit data. A valve mechanism modulates the mud pressure, creating binary-coded pulses that propagate to the surface. These pulses are detected by pressure transducers and decoded into meaningful data, allowing effective communication between downhole and surface.

- Electromagnetic (EM) telemetry: Employs low-frequency electromagnetic waves to transmit data through the geological formation. This method is particularly useful in unbalanced drilling scenarios or when mud pulse telemetry is impractical, offering a viable alternative for data transmission in challenging conditions.

- Wireline drillpipe: An advanced technology that integrates electrical conductors into the drillstring, enabling high-bandwidth, bidirectional data transmission. This method offers significantly higher data rates compared to conventional telemetry methods, enhancing the ability to obtain and process real-time information during drilling operations.

These data transmission technologies are essential for efficient monitoring and control of drilling and production operations, ensuring optimal resource management and safe and efficient operation in the oil and gas industry.

Technological advances in subsea oil exploration

Technological advances have transformed the subsea oil and gas exploration industry, enabling more efficient and accurate means of identifying and extracting hydrocarbon sources. These technologies and techniques are critical to reducing exploration risks and improving the overall efficiency of the industry.

- 3D and 4D seismic surveys: Seismic surveys are essential for mapping subsurface structures. They involve sending seismic waves into the ground and recording reflections. This data helps create detailed images of geological formations and potential reservoirs. 4D seismic monitoring: This advanced technique tracks reservoir changes over time, providing information on reservoir behavior and optimizing production strategies.

- Satellite imagery: Satellites equipped with a variety of sensors take high-resolution photographs of the Earth’s surface. This information is used to track changes in terrain, vegetation and land use, which helps identify potential exploration sites. Drones and aircraft equipped with specialized sensors allow aerial surveys to be conducted by collecting detailed data on specific areas, even in remote or inaccessible locations.

- Wireline logging: To evaluate parameters such as rock density, porosity, resistivity and fluid composition, logging tools are placed in a wellbore. This information helps determine reservoir properties. Analysis of drilling mud for hydrocarbon content and geological information provides real-time information on subsurface conditions.

- Well logging simulator: A well logging simulation system is a software application used in the oil and gas industry to mimic the propagation of electromagnetic waves through the geological strata surrounding a wellbore. During the drilling operation a “logging tool” is dropped into the wellbore to collect data about the rock formations and fluids surrounding the wellbore. This information is used to build a picture of the subsurface and identify potential hydrocarbon reserves.

- Steerable rotary systems: these drilling systems allow operators to steer the direction and trajectory of the drill bit, allowing them to access deposits that are not directly below the drill site.

Computer software technology in subsea exploration

Visual technology consists of the use of advanced computer technology to collect all kinds of geological data during exploration, through a special program, in a visual effect of the image, improve visualization in exploration.

It is very useful to adopt the basin simulation method in the geological exploration of oilfields in basin areas. Traditional basin modeling techniques, which mainly use flat models, have great disadvantages in terms of accuracy, clarity, and information.

However, advanced computer software technology uses 3D modeling technology to improve accuracy and clarity, laying the foundation for smooth oilfield development.

Conclusions

As the oil and gas industry expands into deeper and more difficult offshore locations, the latest advances in subsea technologies are critical to overcoming the technical challenges of deepwater subsea exploration and ensuring long-term, sustainable operation.

These advances not only improve the accuracy and effectiveness of exploration procedures, but also reduce the ecological impact of offshore activities.

Oil and gas exploration remains a critical component of the global energy landscape, providing the resources that drive our industrial world. The industry continues to adapt to the changing energy situation through innovative technologies, responsible practices, and a dedication to sustainability.

References

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC11124795/

- https://onepetro.org/books/book/74/chapter-abstract/14369580/Directional-Drilling?redirectedFrom=fulltext

- https://www.researchgate.net/publication/377676695_Calibration_of_accelerometer_and_magnetometer_sensors_of_MWD_systems_in_direccional_drilling_application

- https://www.esimtech.com/a-comprehensive-guide-to-know-oil-and-gas-exploration.html

- https://kissflow.com/solutions/energy/oil-and-gas-technology-trends/