Introduction

The field of storage tank inspections comprises in-service and out-of-service inspections of vertical and horizontal above-ground and subway tanks. A combination of techniques including engineering calculations according to API 653 and API 650 and other relevant specifications are used to perform a comprehensive inspection of the overall condition of the base, walls, shell and structure of a tank.

The following equipment and techniques are used in storage tank inspection: Base scanning (magnetic flux leak testing and SLOFEC™) – corrosion detection and measurement; Wall crawler tracks – ultrasonic examination of wall plates; Laser examinations (3D and conventional); Long range ultrasonic phased array – inspection of critical junctions between wall and annular reinforcements in tanks, without interruption of service; Conventional non-destructive testing – ultrasonic testing, magnetic particle, vacuum leak testing, etc.

Inspections according to American API (American Petroleum Institute) standards are important to avoid not only catastrophic failures, but also problems related to their mechanical integrity affected mainly by corrosion in floors, walls and ceilings.

External Tank Inspection

Although the external inspection includes several stages, one of them the visual inspection of the entire body of the tank, and therefore of all its external elements, and the measurement of the thickness, ultrasound inspection of the walls and more specifically we will describe the equipment for carry out the inspection in the most efficient way possible.

Today, one of the references in almost all inspection companies for the measurement of thickness in tank walls is the UT CRAWLER (Figure 1).

It is typically designed to perform cost-effective UT thickness measurements on the surface of ferromagnetic structures without the need for scaffolding or rope access (Figure 2). UT trackers can operate automatically or manually. They are used to perform line scans on the surface of the tank shell or specific scans including the roof (with more sophisticated XY scanners). In most cases, the tank shell is divided into 8, 16 or more equal sections as specified by inspection regulations.

B-Scan UT data is recorded for each section from bottom to top, showing the condition along each course. The speed of the UT Tracker and the rate of data acquisition play an important role in the efficiency of tank wall surface inspections.

Some devices can travel and inspect at speeds of up to 180 mm/s (7 in/s) with a dry-coupled wheel probe, eliminating the need for the complex water supply system often required for UT inspections .

Inspection Benefits

Ultra-fast tank inspection for EEMUA 159, API 653 and others,Typical inspection of a medium-sized tank in 4 hours, results reported in Excel (Figure 3)

• Typical inspection time of 15 min per scanline with CAL/SETUP/INSPECTION

• 16 inspection scan lines

• There’s no water

• Scan up and scan down (DOUBLE PRODUCTIVITY)

• No confined space entry / NO scaffolding / Safe

Not a random check

And EXCEL data reporting in minutes!

Continuing with the inspections that we can do externally, there is one in which special paid interest should be put, due to the potential catastrophic failure that it can cause!

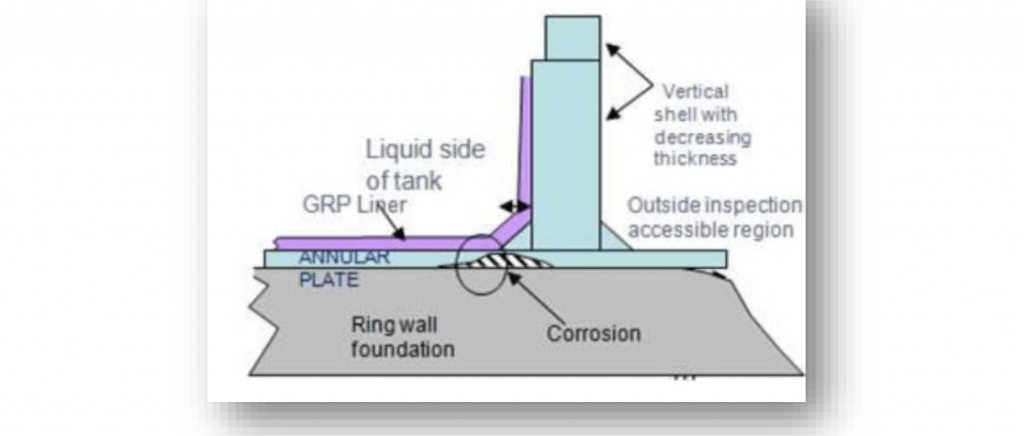

The annular plate region of aboveground storage tanks is critical to their integrity (Figure 4), as it has the highest mechanical stress. At the same time, sagging of the tank can open the seal and expose the bottom to air. and water to initiate corrosion. If left unchecked, the tank can catastrophically fail, releasing its contents in a short time.

Challenges in storage tank annular plate

• The annular plate region is prone to accelerated corrosion due to additional stresses caused by the weight of the tank wall and increased possibility of water entrapment under the annular plate.

Therefore, conventional inspection techniques fall short of capturing the desired data.

• Repairs in this region require replacement of the entire annular plate and this leads to a long tank shutdown, often leading to failures without prior indications.

• Stopping for inspection leads to lost time emptying and filling the tank and significant amount of lost revenue for asset owners.

So how are we going to inspect the annular plate of the storage tank without shutting it down?

Two ways! The first: Pulsed Eddy Currents (PECs) are perfectly suited to meet this challenge. PEC is an advanced electromagnetic inspection technology used to detect wall losses, such as corrosion and tank thinning in ferrous materials.

A flat PEC probe is inserted under the tank floor for in-service inspection (Figure 5). Such an inspection is of great value, as it can help extend the intervals between out-of-service inspections.

The tank floor probe is specifically designed for this type of inspection. With its super-thin 4.8 mm (0.2 in) titanium blade and lift-off tolerance of up to 13 mm (0.5 in), the probe can slide up to 400 mm (16 in) below the edge of a tank floor , allowing you to assess the remaining wall thickness of this critical region exposed to corrosion.

The probe also has built-in remote controls and status LEDs, allowing one operator to perform the inspection. Additionally, the bottom of the tank floor probe is magnetically shielded, maximizing sensitivity for optimal component analysis and protection against signal distortion from potential ferromagnetic structures. Finally, the probe’s titanium blade is designed to withstand the harshest field conditions. Intuitive and quantitative data: Scanned images (Figure 6), as well as other tools included in the software, allow quantification of wall loss.

The second method! Short Range Guided Wave (SRGW): The technique was created for the detection, imaging and evaluation of pitting corrosion damage in the fillet weld area up to 100 mm (4 inches) inside storage tanks above soil. This in-service inspection is performed from outside the tank using the PA probe located on the outer lip of the plate annular ring and does not require emptying the tank, so it can be done at any time when necessary (Figure 7).

The most impressive thing about this technique is how it shows results (Figure 8)!

Comprehensive post-processing including:

• Retrieval and evaluation of A-Scans captured from recorded cross-sectional views (sector

scan) and C-scan

• Retrieval of cross-sectional views of the registered C-Scans

• Conversion of recorded C-Scan or its segments into 3D images

• Defect sizing including quantitative evaluation of thickness loss

• Creation of a list of defects and storage in a separate file

• Automatic creation of inspection reports – hard copy/PDF file

Do not miss the next article on internal tank inspection: Corrosion detection on storage tank floors.

If you want to know more about these and other techniques, get in touch with us!