Table of Contents

- What are Greenhouse Gases (GHG)?

- Process units that generate the most emissions in a refinery 1

- Main polluting sources during refining processes

- Importance of reducing emissions during refining processes

- Sustainable strategies for reducing emissions in oil refining

- Innovative technologies to reduce emissions in oil refining

- The commitment of companies

- Conclusions

- References

The oil and gas industry is one of the main sources of greenhouse gas (GHG) emissions, responsible for climate change. Oil refining , in particular, is a process that generates a large amount of emissions, mainly carbon dioxide (CO2).

Decarbonizing an oil refinery requires complex and realistic plans. The level of emission of polluting gases from each refinery varies depending on certain factors such as: its size, the type of oil that is processed, the fuels it uses and the energy sources it consumes.

This article considers and explores the strategies and technologies that can reduce CO2 emissions in refining processes; where in the current context of climate change, greenhouse gases (GHG) associated with this sector have increased due to the increase in energy consumption worldwide.

What are Greenhouse Gases (GHG)?

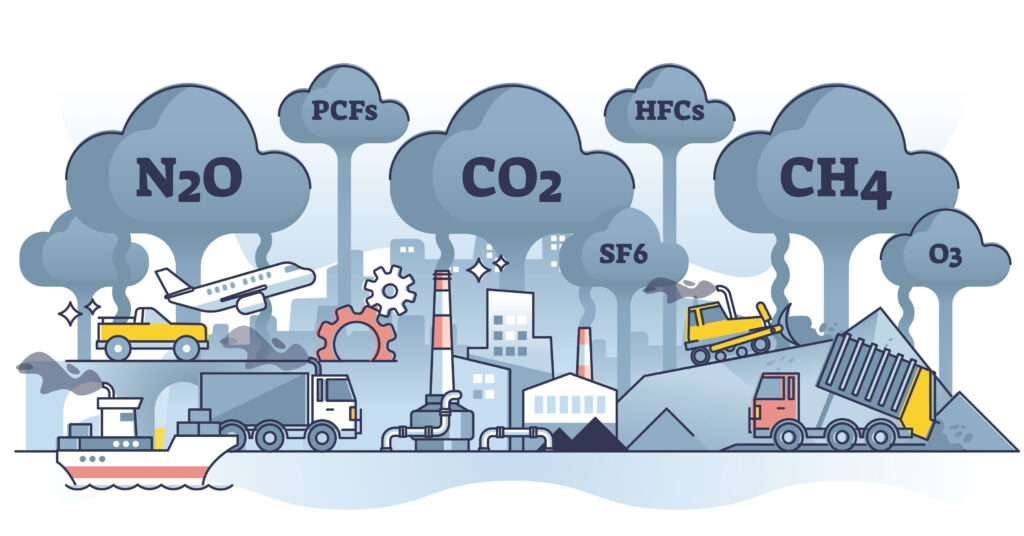

They are gaseous components of the atmosphere, natural and resulting from human activity, that absorb and emit infrared radiation; This property causes the greenhouse effect. The main gases that contribute to this phenomenon are carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O) and fluorinated gases, of which CO2 is the most polluting (figure 1).

In the context of refining processes, GHGs are mainly produced by the combustion of fossil fuels to generate energy. Oil, natural gas and coal contain carbon, which is released into the atmosphere as CO2 when burned.

Process units that generate the most emissions in a refinery 1

There are more than 1,000 oil refineries in the world, which are basically classified into two types: hydrodesulfurization or hydrotreating refineries which produce gasoline, jet fuel and middle distillates, and the largest conversion refineries include hydrocrackers and catalytic cracking units for further reduce heavy crude oil fractions and convert them into lighter products.

The largest conversion refineries emit about four times more CO2 per barrel of oil than hydrodesulfurization refineries. In order of importance, the refining units that generate the most pollution are mentioned:

- Power plants, which generate the energy necessary to operate the process units.

- Fluid catalytic cracking units , which convert heavier crude oil fractions into lighter products.

- Atmospheric distillation units, where the different fractions of the crude oil are separated.

- Steam methane reformers, which produces hydrogen for the process units.

Main polluting sources during refining processes

Refining crude oil is a complex process that involves a series of stages to convert it into finished products. As these processes are carried out, pollutants are emitted that have a negative impact on the environment and human health. Among the main sources are:

- Combustion of fossil energy: Refining is energy intensive and requires significant amounts of energy for its processes; This is obtained from fossil fuels, and when combustion occurs, it emits carbon dioxide and other pollutants such as nitrogen oxide and sulfur dioxide.

- Waste treatment and storage: Inadequate management of waste and dangerous byproducts from processes generates pollution to ecosystems.

- Gas Flaring: Flaring or venting excess gas using flares is a common practice in refineries. Although it serves to get rid of gases under safe conditions, these processes emit a large amount of CO2 , methane and other polluting gases.

- Spills or leaks: Spills, accidental leaks or intentional releases of vapors, gases or products, which occur during operational processes, generate atmospheric pollution.

The sum of all these emissions has a significant environmental impact, which requires precise internal management and appropriate technologies so that they are minimized and thus, the oil and gas industry can move towards a sustainable future.

According to World Energy Outlook special report on the oil and gas industry and COP28, titled ” Emissions from oil and gas operations in net zero transitions “:

“Today, oil and gas operations account for around 15% of total energy-related emissions globally, the equivalent of 5.1 billion tonnes of greenhouse gas emissions. “In the International Energy Agency’s 2050 net-zero emissions scenario, the emissions intensity of these activities falls by 50% by the end of the decade.”2

Importance of reducing emissions during refining processes

It is a necessary action to reduce negative effects on the environment, comply with global climate objectives and strict environmental regulations, improve the sustainability of the sector and adapt to an economy in transition towards cleaner and renewable energy sources, which help in the fight against climate change and global warming.

Climate change is one of the main threats facing humanity, and it is a priority to address it effectively and urgently. Its effects are being felt around the world, in the form of extreme weather events with changes in atmospheric circulation patterns, increases in the average temperature of the earth, rise in sea levels due to thermal expansion of water and considerable loss of biodiversity. On the other hand, it is of utmost importance for public health and the reduction of disease incidence.

Sustainable strategies for reducing emissions in oil refining

With growing concerns about environmental sustainability, effective strategies need to be developed and implemented for a transition towards carbon-neutral operations. Among the main strategies are:

- Energy efficiency improvements: Focuses on reducing energy consumption during refining processes, to effectively reduce emissions. Implementing innovative technologies, updating existing processes and maximizing waste heat recovery improves energy use and minimizes waste. These are cost-effective mitigation strategies, although they only allow a modest 5-10% reduction.

- Integration of renewable energy sources: It is an effective option in this transition process, the generation of renewable energy, the production of hydrogen with low carbon emissions and the electrification of processes are valued strategies.

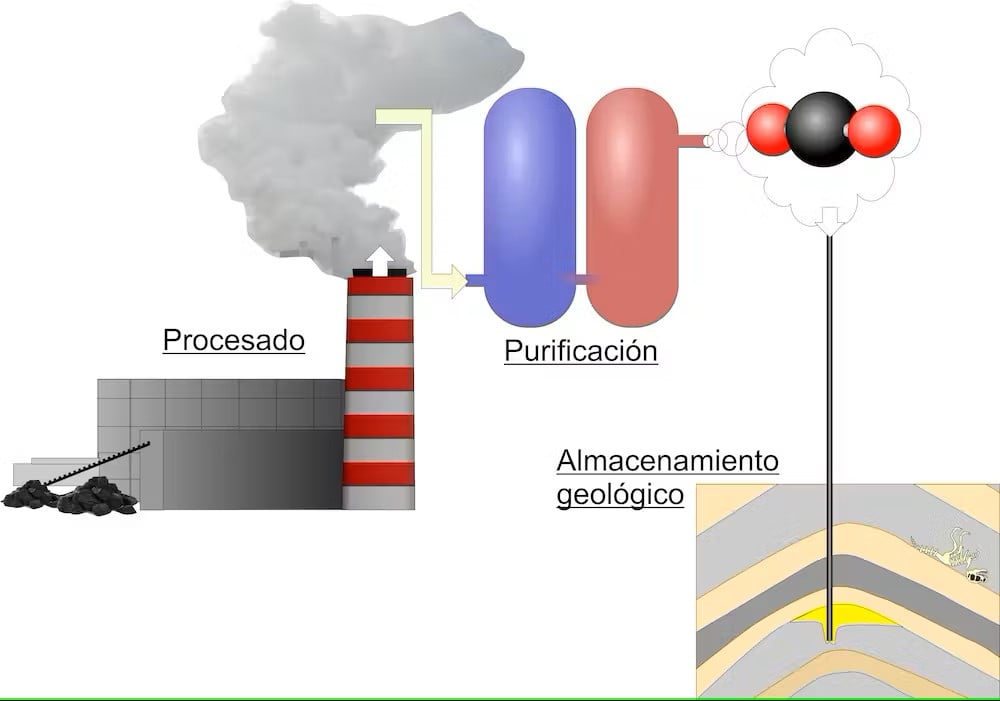

- Carbon capture and storage (CCS): It is a promising technology to capture and store CO2 emissions, safely for future use. There are various forms, these can be in the pre-combustion or post-combustion of the refining processes.

- Increased efficiency of processes: Implementing advanced techniques to optimize and control processes increases efficiency in operations, influencing the reduction of energy consumption.

- Integration of digital technologies: Digital solutions such as artificial intelligence and data analysis to optimize operations, predict maintenance and improve decision making.

- Training and awareness: It is essential to establish a culture of environmental sustainability in companies. Employees driven by leaders must be trained and committed to promoting sustainable habits in each environment where they work.

- Monitoring and control of emissions: Implement monitoring and data analysis systems that allow refineries to maintain control over their emissions. Correct management of these systems contributes to the identification of potential areas for improvement, demonstrating the commitment of oil organizations to the preservation of the environment.

- Regulations and regulations: They are necessary tools for the oil industry to regulate its emissions and move towards more sustainable and environmentally friendly operations. The future of this sector depends on its ability to manage its carbon footprint. If this action is applied collectively, important improvements are achieved.

It is essential to develop and implement cost-effective emissions mitigation strategies for refineries to remain operational within a society that remains in pursuit of net zero.

Innovative technologies to reduce emissions in oil refining

In recent years, in order to establish a long-term path towards emissions reductions, the oil sector has been developing and implementing a set of technologies to decarbonize its processes. Among the newest are:

Process optimization: Developing more efficient refining processes with respect to energy use, modernizing and automating existing systems, through the integration of digital technologies, can reduce CO2 generation by 10-20%. “One of the key advances is found in the loading of protection reactors with fresh catalysts, without the need to disconnect a unit, guaranteeing continuous and efficient operation of the facilities” 3

Carbon capture and storage (CAC or CCS): It is a promising technology to capture and store CO2 emissions from the atmosphere. CCS consists of separating CO2 emitted by industry and energy generation in the combustion processes of refining processes, capture it and transport it to a geological storage location to isolate it from the atmosphere in the long term, in order to use it in the future, as you can see in figure 2. This technology is increasingly advanced and its implementation reduces emissions by 90-95%.

For example, CANSOLV CO2 is a leading Shell technology for gas treatment and CO2 recovery. It uses a regenerable amine, standing out for its low energy consumption, kinetics, minimal volatility and high resistance to degradation in gases with oxygen. This technology assists companies in complying with environmental regulations. It has captured more than 5 million tonnes of CO2 from the Saskpower Boundary Dam facility in Canada.

Biofuels: They are used as substitutes for fossil fuels in multiple refining processes. These are less polluting.

These technologies must be adjusted to minimize environmental impact and emissions, while ensuring that they are cost-effective to increase access and, in turn, energy savings.

The commitment of companies

Repsol

In its commitment to zero net emissions in 2050, it was the first company in the sector to set an ambitious goal in favor of the planet, and in its 2021-2025 Strategic Plan it set demanding commitments on the path to decarbonization. They reduce emissions from their production processes and, in addition, contribute to reducing the environmental footprint of their clients with solutions and products with a low and neutral carbon footprint. All, thanks to a firm commitment to technology and digitalization.

Petrobras 4

Has formed an alliance with the Japanese manufacturer Kureha to develop carbon capture technology on offshore oil platforms. They plan to capture GHGs and convert them into valuable products, such as batteries and car parts. Kureha is developing a catalyst to break down methane into hydrogen and carbon at its research facility, with plans to test a small-scale prototype on a platform. The goal is for the technology to be commercially available by 2030, aligning with the company’s net-zero emissions goals.

Strategies to reduce emissions in oil refineries in the US 5

As U.S. oil companies adapt to a more sustainable future, they must continue operating while significantly reducing their emissions. An example is the state of Washington, where it has been shown that refineries can reduce their emissions by 40% and the carbon intensity of their products, without having to close the facilities.

Five key ways are proposed to minimize climate pollution from refineries:

- Convert smaller refineries to produce sustainable aviation fuel (SAF)

- Commit to reducing methane leaks

- Electrify or shut down units that require a lot of heat

- Replace all gray hydrogen with green hydrogen

- Implement carbon capture and utilization (CCU) in waste gas streams concentrated in FCC units

“Washington has the opportunity to lead the nation in reducing emissions from oil refining. “Washington’s refining sector is likely to reduce its emissions by 2.36 million tons of CO2 annually by 2030.”

Conclusions

Reducing the carbon footprint in refineries is a challenging job that requires a detailed evaluation of several technological and operational factors. However, through appropriate strategies, such as operational efficiency, carbon capture, emissions monitoring, integration of renewable energy sources and financial stimuli, emissions are considerably reduced, leading to progress towards a more sustainable and beneficial future.

It’s a long road, but the oil refining industry has the capacity and resources to reduce emissions in its processes quickly and accurately. Those that act early to slow down will be able to gain a significant competitive advantage in an evolving energy environment.

References

- Solado Nixon, et al. “Computational methods in chemical engineering”; Forehead. Chemistry. Eng, Volume 4 – 2022; https://www.frontiersin.org/articles/10.3389/fceng.2022.804163/full

- International Energy Agency (IEA); “Emissions from oil and gas operations in net zero transitions” Published June 2023; https://www.iea.org/reports/emissions-from-oil-and-gas-operations-in-net-zero-transitions

- Market A; “Petroleum Refining Processes: How Crude Oil is Transformed into Useful Products”; published September 22, 2023; https://www.adrianmercado.com.ar/blog/processes-de-refinacion-de-petroleo/

- VilelaA ; “Petrobras and Kureha form alliance to capture carbon on the Brazilian high seas”; h2businessnews, published 2023-08-28; 2023-08-28; https://h2businessnews.com/petrobras-y-kureha-forman-alianza-para-capturar-carbono-en-alta-mar-de-brasil/

- Drew Veysey, Meghan Peltier and Joseph Fallurin; ” Five Ways U.S. Oil Refineries Can Reduce Emissions Today “; published June 5, 2023; https://rmi.org/how-to-slash-refinery-emissions-quickly-washington-state/