Summary

Laser Induced Plasma Spectroscopy (LIBS) represents one of the most useful techniques for the selection and identification of materials. This article describes a brief summary, the physical principle on which it is based and its most important advantages.

Introduction

Laser Induced Plasma Spectroscopy, known as LIBS, is a type of atomic emission spectroscopy that uses high-energy lasers as an excitation source. One of the great advantages of the technique is the possibility of analyzing any substance independent of the state of aggregation, whether they are solids, liquids or gases, and others. Because all elements of the periodic table emit light when suitably excited, this technique can potentially resolve the elemental composition of any sample, such detection being limited to the available power of lasers and the sensitivity and spectral resolution of spectrometers and spectrometers. detectors, mainly.

The LIBS technique has many points in common with other laser-based analytical techniques (such as Raman or Fluorescence), with most of the instruments being identical. In fact, equipment is available on the market that allows operating with any of these techniques, from objects as simple as high-fidelity audio equipment, to ultra-high-tech laser scalpels for highly delicate clinical operations, or even to maintain communication.

between the Starlink network between satellites (SpaceX adds laser links to Starlink satellites) . This beam of modulated light turned out to be very useful when merging with information processing technologies, generating a spectacular leap in the speed of our telecommunications.

what is a laser?

It is light with very special characteristics. His initials stand for Light Amplified by Stimulated Emission of Radiation , or light amplified by stimulated emission of radiation.

Unlike “spontaneous” light, which is most of the light we perceive (in spotlights, and even sunlight), this type of light is “stimulated.” Thanks to the emission mechanism, the waves do not travel in all directions, but overlap each other and all travel in the same direction. The power then turns out to be higher.

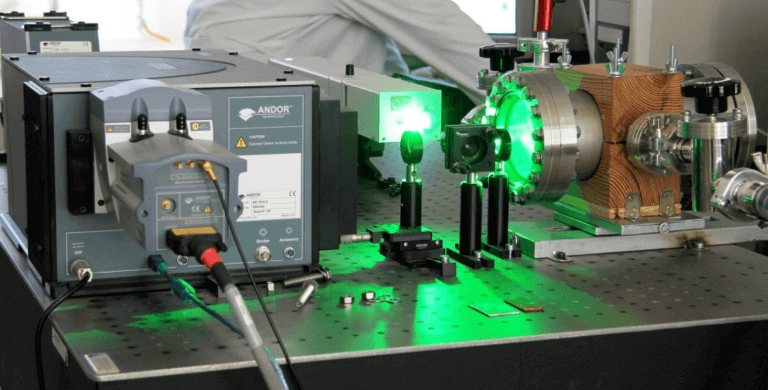

One of the applications in the area of materials is in the detection of alloys through spectroscopy, due to the inclusion of the laser, this technique differs from analytical methods and has been used in laboratories for many years.

Most hand-held LIBS analyzers are used (like similar ones that operate on other principles) to sort and select alloys in scrap yards or receiving/dispatch for identification.

During LIBS analysis, a focused laser pulse strikes the sample, removing a small amount of material from the surface. This material is heated to over 10,000 degrees Celsius. The temperature is so high that the atoms actually “split” and form plasma. Interestingly, the sample does not become warm to the touch during analysis, to the point that it can be safely held in the hand.

When the high power pulsed laser hits the sample, the electrons in the outermost orbitals are displaced. But since these outer electrons are shielded by those in the innermost shells, they are not strongly pulled by the nucleus. Thus, these outer shell electrons will need less energy to be ejected. Analogous to the previous methods, the ejected electrons create a vacancy, which generates an instability in the atom, analogously.

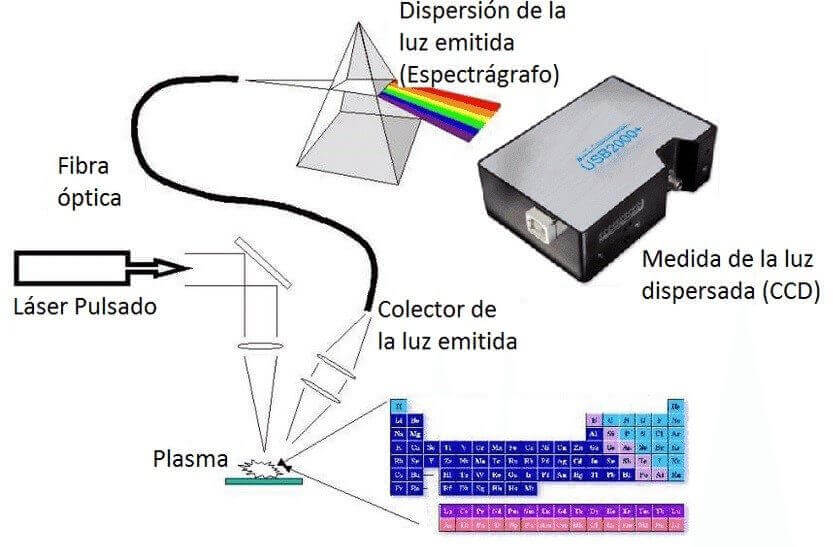

Once the light pulse ceases, the plasma begins to cool and the vacancy is occupied by electrons coming from the outermost layers, in the form of a cascade. The excess energy released when electrons move between two energy levels, or orbital shells, is then emitted as light characteristic for each element. Said light is transported via fiber optics to the elements necessary for its processing.

For a typical metallic sample containing either iron, nickel, chromium, manganese, or vanadium, each element emits many wavelengths, generating a spectrum of up to thousands of peaks. These wavelengths of light are collected through a fiber optic cable and then processed with the spectrometer (Figure 1).

Each element is associated with a specific spectral peak. LIBS spectra are very complex, with potentially hundreds or even thousands of lines for each element, then from the intensity of the peak, the composition is determined through suitable algorithms. These also identify the type of sample.

One of the most important advantages of Laser Induced Plasma Spectroscopy (LIBS), with respect to other existing technologies, is its speed in the analysis and identification of alloys, taking just one or two seconds, that is, up to 20 times faster. that X-Ray Fluorescence (XRF). This can become very important in processes where high productivity and precision is important.

From the point of view of regulations and licenses, there are few requirements for the operator, with respect to other techniques such as XRF. Expensive licenses or lengthy training are generally not needed, the precautions regularly needed are: Special safety glasses that protect against Class 3B laser emission.

The basic differences between the spectroscopy methods consist in the way of exciting the electrons of the upper layers, in order to displace them and generate the vacancies, to produce the secondary emission of light when the electronic movement is generated at said vacancies. Each technology has a different form, although broadly speaking the principle is the same: spectroscopy.

Finally, it can be concluded that the LIBS analytical method is quite practical and excellent for the identification of the elements present in alloys.

We hope that this simple opinion and general information will allow the reader to have a clearer vision regarding the Laser Induced Plasma Spectroscopy Technique (LIBS).

References:

SpaceX adds laser links to Starlink satellites

Source: www.laseroptics.com.ar/Flibs.html

About the Author.

ing Jose Martinez de Munck. 15 years of experience in Equipment Inspection for the Oil and Gas Industries.