Introduction

Boilers are closed vessels with gas or electric burners to generate steam from liquid water. The steam is under pressure and superheated, and is used to generate electricity, for heating, or for other industrial purposes. They are normally equipped with a pressure relief valve, if the boiler cannot withstand the pressure, the energy contained in the steam is instantly released causing extremely dangerous damage.

Do you really know how safe your boiler is?

Did you know that from 2016 to date, at least 17 explosions of small and large, old and totally new boilers have been reported in the media and social networks, at the level of Latin America, after their installation and operation that caused 15 losses

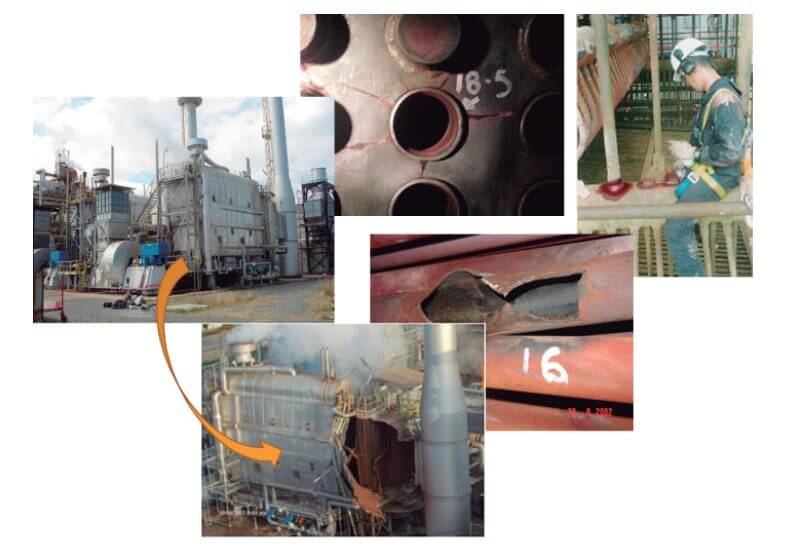

human lives, more than 45 injured, and great material losses? Many of these accidents occurred in countries with Boiler Installation, Operation and Inspection Regulations that are well disseminated, established and apparently well controlled by the jurisdictions. Figure 1 shows images of an accident that occurred in boilers.

International standards and codes for the maintenance and operation of boilers

What is happening? What is not being done? Could it be that the level of risk involved in using a boiler and the care that must be taken are not clear?

Do you know the requirements of the local regulations for the use of boilers? Do you know the standards and codes that govern the use and care of boilers internationally?

Most of the periodic inspections required by the regulations of our Latin American countries require:

• A general internal and external visual inspection.

• A hydrostatic test.

• The evaluation of the functionality of the alarm system and

shots.

• Tripping (opening) and closing tests of the valves

security.

In the southern countries, in the inspections required by their regulations, it is required to carry out accumulation tests on the pressure relief valves to verify their capacities to dislodge the steam produced by the boiler.

It must be clear that the boilers begin to age the same day they are turned on for the first time; So, will it be enough to do the same inspection every year to know

if the boiler is safe?

In several regulations, as the time of operation of the boiler goes by and, at the discretion of the accredited inspectors, extraordinary inspections must be carried out, which go beyond the scope of the regulatory periodic inspection, but which in most cases do not They go beyond thickness measurements and do some dye penetrant tests on welds. However, the damage mechanisms by which materials age are not observed by measuring thickness.

To define which part of the boiler to inspect and with which test method the evaluation will be carried out, it is necessary to analyze and define what could be the damage mechanisms that can occur in the various components of a boiler; this depending on the history of operation, the quality of the water and the

water treatment controls, type of fuel being burned and combustion controls, how the boiler is preserved when out of service, and operating procedures (start-ups and shutdowns); from which we can conclude that this has to be a team work

multi-disciplinary.

From an evaluation of this type, it will be possible to define the level of mechanical reliability and/or levels of aging and, of course, what should be the scope of the next maintenance in the short and medium term. The methodology used to carry out this type of evaluation is known as Risk-Based Inspection, and there are standards that can guide this methodology; Some to cite could be:

• The Post Construction Code of ASME PCC 3: “Inspection Planning Using Risk-Based Methods”

• API Recommended Practice RP 580: “Risk-Based Inspection”.

• General Boiler Inspection Guidelines in Part 2 “Inspection” of the National Board’s Boiler and Pressure Vessel Inspection Code.

• The Condition Assessment Methodology, which was initially proposed by the Babcock & Wilcox boiler factory, and later promoted by EPRI.

Boiler safety levels

There are many questions that can and should be asked to assess the safety and reliability levels of your boiler, but we will do some of them to find out if your boiler is protected against loss of water level and overpressure:

Water level loss: How often do you calibrate the boiler instrumentation? During periodic inspections or maintenance, are the alarms and trips of the boiler due to low level verified? How often do you disassemble and clean the rods or float that actuates the switch?

boiler shot?

In case of overpressure events: How often do you check 28 the opening pressure of the pressure relief valves (safety valves) against a calibrated pressure gauge?; When you replace one of the pressure relief valves (safety valves) on your boiler, do you know what the criteria are for selecting the new valve? Do you know if that valve complies with the requirements of the design code and ASME manufacturing and the National Board inspection and installation code? Is that valve for steam service?

In addition, there are many other questions to ask if you want to do a full audit of your boiler’s safety and reliability levels, having to do with routine operating practices (including operator training), quality controls water and controls

the combustion.

So far we have made reference to two Codes and a Recommended Practice that are focused on mechanical evaluation and inspection, but if you want to comprehensively define the evaluation of the safety levels of the boiler, it must be verified —after installation, before its first ignition and then

of a time of operations and maintenance—how far the boiler has deviated from what is established by the Hazard Codes for Boilers and Combustion Systems NFPA 85 and/or the Code of Controls and Safety Devices for Automatic Fired Boilers of ASME CSD 1 because, in many

opportunities due to ignorance of what is established by these codes and the reason for them, there are maintenance personnel who make modifications that move the boiler away from the requirements

security minimums.

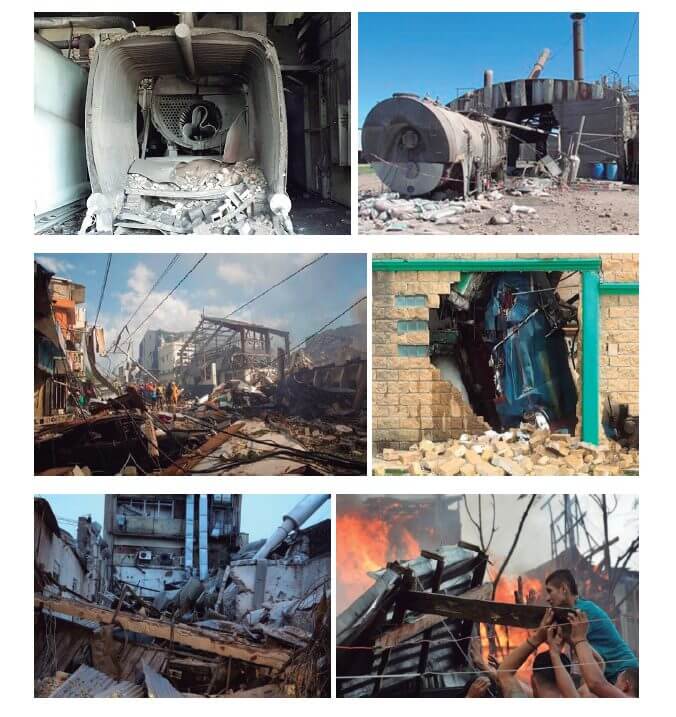

Boiler accidents in Latin America 2018

In this section you can see the links to web sites, where some accidents due to small (fire-tube) and large (water-tube) boilers in our Latin American countries are shown, and the balances of the damages that these explosions left behind. In Figure 2, images of some of these accidents are shown.

Dominican Republic – December 5, 2018

https://www.elnuevoherald.com/noticias/mundo/america-latina/article222678755.html

At least three people were killed and 44 others injured in a boiler explosion at a plastics factory in Santo Domingo. Among the injured were 13 children who attended a school located opposite the Polyplas company, where the explosion occurred.

Guatemala – November 10, 2018

https://www.publinews.gt/gt/noticias/2018/11/10/guatemala-explosion-caldea.html

A member of the industrial team, who held the position of Superintendent of Power Generation, died due to the explosion of a steam pipe at the La Unión mill. The incident occurred inside the plant located in Santa Lucía Cotzumalguapa, in Escuintla.

Colombia – October 18, 2018

https://www.eltiempo.com/colombia/medellin/dos-muertos-por-incendio-en-el-corregimiento-de-san-cristobal-de-medellin-282852

A structural fire occurred due to the explosion of the boiler of a waterproofing materials factory in the Boquerón village of the San Cristóbal corregimiento, in Medellín.

The incident caused the death of two people and injuries to another.

Columbia – June 12, 2018

https://noticias.caracoltv.com/ojo-de-la-noche/exploto-caldera-en-bogota-un-pedazo-vuela-30-metros-y-destroza-busdel-sitp-ie26636

A boiler exploded in the Isla del Sol neighborhood, Tunjuelito, in Bogotá. A piece flew 30 meters and destroyed a SITP bus. One person was injured when a fragment fell into

the parking lot

Peru – April 17, 2018

https://publimetro.pe/actualidad/noticia-cercado-lima-fallecen-dos-trabajadores-fabrica-explosion-caldero-video-73039

Two workers from a factory located on Argentina Avenue died due to a cauldron explosion that removed the structures of a warehouse inside the Magensa factory dedicated to the manufacture, import and sale of furniture and decoration items. Their bodies flew about 20 meters, according to witnesses.

Columbia – January 14, 2018

http://barrancabermeja.extra.com.co/noticias/judicial/explosion-de-una-caldera-en-ingenio-rio-paila-castilla-dejo-382421

The explosion of a boiler in the Río Paila Castilla mill located in the municipality of Zarzal, Valle del Cauca, left one dead and three injured. The incident occurred when some workers from the hydrowashing sector tried to open a Kesther boiler and it exploded. A worker came to

health center without vital signs as a result of the burners. The injured presented first and second degree burns in more than 90% of the body.

References

Own source.