Table of Contents

- Forms and classification of corrosion

- Importance of understanding CUPS

- Causes and mechanisms of CUPS

- Detection and inspection techniques for CUPS

- Inspection techniques for Corrosion Under Pipe Supports (CUPS)

- Prevention and maintenance strategies for CUPS

- Industry applications of CUPS knowledge

- Case Study: QSR1 Technology by Guided Ultrasonics Ltd

- Future trends in CUPS prevention and management

- Conclusion

- References

Corrosion is a natural process that affects all metals and causes deterioration over time. In industrial environments, particularly in the oil and gas, chemical processing, and power generation industries, pipeline corrosion is a significant challenge. Not only does it affect the structural integrity and longevity of equipment, but it also leads to costly maintenance and repairs, and even catastrophic failures.

Corrosion under pipe supports, commonly known as CUPS (Corrosion Under Pipe Supports), is a critical problem in industries, as it affects the life and safety of piping systems. It occurs at the contact points between pipes and supports, where moisture and corrosive agents accumulate, causing deterioration. This type of corrosion, difficult to detect in inspections due to its low visibility, can cause unexpected failures, leaks, and serious incidents.

In this article, we will delve into the nature of CUPS, exploring its causes, identifying signs of damage, and discussing best practices for inspection, corrosion prevention, and maintenance. Understanding how corrosion problems develop in pipelines under supports and implementing effective mitigation strategies is critical to ensuring the safety, reliability and efficiency of industrial operations.

Forms and classification of corrosion

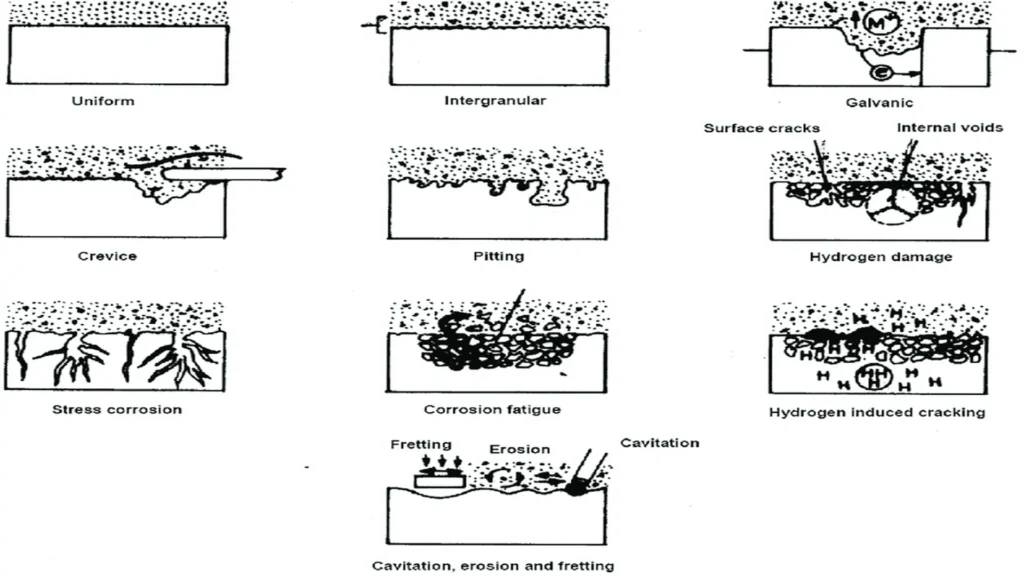

Fontana, has classified the forms in which corrosion manifests itself. The basis of this classification is the appearance of the corroded materials. Fontana1 has mentioned 8 forms of corrosion, more or less related to each other. The 8 forms are: (1) Uniform or general attack (2) Galvanic or bimetallic corrosion (3) Crevice corrosion (4) Pitting corrosion (5) Intergranular erosion (6) Selective leaching or partitioning (7) Erosion corrosion and (8) Stress corrosion. These 8 types cover virtually all types of failure and corrosion problems.

Winston Revie & H.H. Uhlig2 have more or less classified the types of corrosion as (1) General Corrosion or Uniform Attack, (2) Pitting, Fretting, Cavitation-erosion, (3) Dealloying Dezincification and Parting, (4) Intergranular Corrosion, (5) Cracking. It can be noted that in both classifications they are more or less the same with a slight modification/difference in nomenclature. the following figure shows the schematics of the common forms of corrosion.

Each type of corrosion occurs through a different mechanism and effect, influenced by environmental conditions, material properties, and operational factors. In addition, the structure, composition, and properties of the metal are often responsible for the corrosion behavior, hence the importance of material selection.

Importance of understanding CUPS

Corrosion pipe under supports (CUPS) significantly compromises the structural integrity of piping systems. By attacking the metal at points of contact, CUPS leads to localized thinning and pitting, weakening the pipe’s wall and support areas. This deterioration undermines the load-bearing capacity of the pipes, making them prone to fractures and leaks. Over time, undetected CUPS can cause catastrophic failures, jeopardizing the entire structural system.

The safety risks associated with CUPS are substantial. Pipe failures due to corrosion can result in the release of hazardous substances, leading to fires, explosions, and environmental contamination. From an economic perspective, the costs of CUPS are equally alarming. Direct costs include repairs and replacements, while indirect costs involve production downtime, environmental cleanup, and potential legal liabilities. Corrosion prevention measures are, therefore, crucial to minimize financial losses and safeguard human lives.

Adhering to industry standards and regulations is essential for effective CUPS and corrosion pipe management. Standards such as API 570 (Piping Inspection Code) and API 580 (Risk-Based Inspection) provide guidelines for assessing and managing corrosion pipe risks. Compliance with these standards ensures that companies maintain high safety and operational reliability, preventing the repercussions of regulatory breaches and enhancing overall plant safety.

Causes and mechanisms of CUPS

CUPS is primarily driven by environmental conditions. Moisture trapped between the pipe and its support creates an ideal environment for corrosion. Temperature fluctuations exacerbate the problem by causing condensation, which promotes the accumulation of water and accelerates corrosive processes. Exposure to corrosive agents, such as saltwater or chemical vapors, further aggravates the situation, leading to faster degradation.

The susceptibility of pipes to CUPS is influenced by the materials used and the design of the pipe support. Materials that are prone to corrosion, such as carbon steel, are more vulnerable to corrosion pipe issues, especially in environmental conditions where protective coatings are compromised. Design flaws, such as poor drainage and tight clearances, can trap moisture and debris, creating crevices where corrosion can initiate and thrive.

CUPS is largely driven by electrochemical reactions, where the presence of water acts as an electrolyte. This environment allows for the transfer of ions, causing the metal at the point of contact to oxidize and deteriorate. Over time, this leads to the formation of rust and pitting, which compromise the integrity of the pipe. Understanding these mechanisms and the role of environmental conditions is key to developing effective corrosion prevention strategies.

Detection and inspection techniques for CUPS

Detecting CUPS is challenging because it occurs in hidden areas where pipes rest on supports. These locations are not easily accessible for visual inspections, often leading to overlooked corrosion issues. Routine inspections may miss CUPS due to the lack of direct visibility, making it a hidden threat that can escalate undetected until a major failure occurs.

Several NDT methods are effective for detecting CUPS. Ultrasonic testing (UT) is widely used to measure wall thickness and detect thinning in areas not visible to the naked eye. Radiographic testing (RT) can provide images of the interior of pipes and supports, highlighting areas of corrosion. Eddy current testing (ECT) is another method suitable for identifying cracks and surface flaws associated with CUPS.

To enhance the detection of CUPS, advanced technologies such as drones and robotic crawlers are employed. These devices can access hard-to-reach areas, providing detailed visual inspections without the need for scaffolding or shutdowns. Infrared thermography is also valuable, as it can detect temperature variations indicative of corrosion activity or insulation failure, helping to pinpoint CUPS locations.

Implementing regular inspection schedules is critical for early detection and management of CUPS and corrosion pipe issues. Scheduled inspections, combined with continuous monitoring systems, allow for the timely identification of corrosion issues before they develop into severe problems. By adhering to a proactive inspection regime, companies can significantly reduce the risk of unexpected failures and costly repairs, ensuring long-term operational safety and reliability.

Inspection techniques for Corrosion Under Pipe Supports (CUPS)

- Visual inspection: This is the initial and most basic technique to identify visible signs of corrosion on pipes and their supports. It focuses on detecting rust stains, discoloration, and other indicators of deterioration that might suggest the presence of corrosion under supports. Although not exhaustive, it provides a preliminary indication and can guide the application of more detailed methods.

- Ultrasonic testing for corroboration: Used after visual inspection or corrosion mapping, ultrasonic testing is a non-destructive technique that allows for precise measurement of pipe wall thickness. It is effective in confirming the extent and depth of corrosion at specific points, providing quantitative data on material loss.

- Guided wave ultrasonics: This technique allows for the inspection of long sections of pipe from a single access point. Ultrasonic waves propagate along the pipe and detect the presence of corrosion in hard-to-reach areas, such as under supports. It is particularly useful for identifying changes in material properties that indicate corrosion. Advanced Guided Wave technology combines circumferential guided waves with advanced frequency analysis to quantify wall thickness loss in pipes. This system precisely measures the extent of corrosion, identifying areas where the material has degraded. The technology can detect thickness losses in the millimeter range, providing detailed and quantitative data on the structural integrity of pipes and supports.

To learn more about this technique see the following video. Source: GUL – Guided Ultrasound Ltd.

Detection and sizing of Corrosion Under Pipe Support (CUPS) using Guided Waves.

- Eddy Current Testing (ECT): This technique uses electromagnetic fields to detect surface and near-surface defects in metallic materials. Eddy currents are effective in locating pitting and thickness loss in areas where corrosion may be present, providing a quick and accurate assessment of the surface conditions of the pipe and its supports.

Prevention and maintenance strategies for CUPS

- Design improvements: Preventing Corrosion Under Pipe supports (CUPS) starts with design optimization. Enhancing the drainage capabilities of pipe supports is crucial to prevent moisture accumulation. Support designs should incorporate features like sloped surfaces or drainage holes that allow water to escape easily. Utilizing elevated or adjustable pipe supports can minimize direct contact between the pipe and the support, reducing the crevice areas where moisture can accumulate. Additionally, implementing non-metallic or composite materials in support designs can help break the galvanic coupling that accelerates corrosion.

- Material selection: Choosing the right materials is essential for minimizing CUPS. Opt for corrosion-resistant alloys like stainless steel or duplex stainless steel, which offer superior resistance to corrosive environments. When using carbon steel, ensure that it is properly coated to enhance its durability. The material choice should also consider environmental conditions, such as exposure to saltwater or chemicals, which can exacerbate corrosion.

- Protective coatings and linings: Applying protective coatings to both pipes and supports is an effective barrier against moisture and corrosive agents. Epoxy coatings, polyurethane, and zinc-rich primers are commonly used to provide robust protection. These coatings should be applied with attention to detail, ensuring coverage in hard-to-reach areas. Coatings should be regularly inspected and maintained to prevent degradation and ensure continued protection. Regular corrosion prevention measures include checking the integrity of these coatings in various environmental conditions.

- Cathodic protection (CP) is a technique that minimizes corrosion by making the metal surface the cathode of an electrochemical cell. This is achieved by applying a sacrificial anode or using an impressed current system. CP is particularly useful in underground or submerged environments where CUPS is prevalent. It provides an added layer of defense by neutralizing corrosive reactions, integrating corrosion prevention in the process.

- Routine maintenance and cleaning: Regular maintenance is vital to prevent the buildup of moisture, dirt, and corrosive substances that contribute to CUPS. Scheduled cleaning of pipe supports and surrounding areas can help identify early signs of corrosion. Inspections should be conducted periodically using non-destructive testing methods to assess the integrity of pipes and supports. Corrosion prevention measures ensure that these inspections are consistent and effective, adapting to various environmental conditions.

- Sealants and gaskets: Utilizing sealants and gaskets to close gaps between pipes and supports can prevent moisture ingress. These sealing solutions should be resistant to environmental conditions and compatible with the materials used in piping systems. Proper sealing reduces the risk of moisture entrapment, which is a primary cause of CUPS, thus serving as a corrosion prevention strategy.

Industry applications of CUPS knowledge

- Oil and Gas industry: CUPS is a widespread issue in the oil and gas sector, affecting pipelines, refineries, and offshore platforms. The harsh environmental conditions and constant exposure to saltwater, chemicals, and temperature fluctuations make CUPS a significant concern. Effective CUPS management and corrosion prevention practices are critical to prevent leaks and structural failures, which can lead to environmental disasters and costly downtime.

- Chemical processing plants: In chemical processing facilities, pipes often carry corrosive substances, increasing the likelihood of CUPS. The aggressive nature of chemicals requires stringent corrosion management practices Implementing CUPS prevention strategies, such as using corrosion-resistant materials and protective coatings, is essential to maintain the integrity of process piping and equipment, supported by regular corrosion prevention.

- Power generation facilities: CUPS is particularly relevant in power plants, where cooling water systems and steam lines are prone to corrosion. The presence of moisture and high temperatures accelerates the corrosion process. Regular inspections and corrosion prevention are crucial to prevent CUPS-related failures that could disrupt power supply and cause safety hazards.

- Petrochemical industry: Petrochemical facilities face unique CUPS challenges due to the diverse range of chemicals processed. Pipes in these settings are subjected to varying chemical compositions and operational conditions, increasing the risk of CUPS. Implementing comprehensive inspection and maintenance regimes helps mitigate these risks and ensures operational reliability through effective corrosion prevention.

Case Study: QSR1 Technology by Guided Ultrasonics Ltd

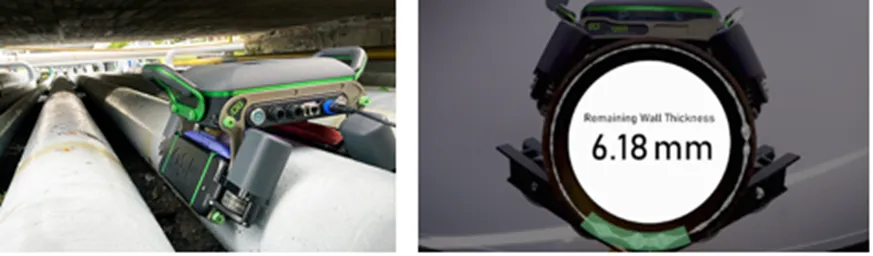

Corrosion Under Pipe Supports (CUPS) poses a significant risk to pipeline integrity, particularly due to the challenges of inspecting areas in contact with supports. The accumulation of water and oxygen in the confined spaces between the pipe and the support accelerates external corrosion, making its detection and accurate assessment difficult due to limited access.

To overcome these challenges, the QSR1 technology from Guided Ultrasonics Ltd uses circumferential guided waves and an innovative frequency analysis method to accurately detect and measure corrosion at pipe supports. This solution allowed for the identification of critical thickness loss, providing reliable measurements of the remaining pipe wall thickness. The data obtained not only prevented potential hazardous incidents but also supported critical decisions regarding structural and operational integrity.

This case study highlights how adopting advanced technologies like QSR1 is key to addressing the challenges of CUPS, ensuring safety and extending the service life of industrial facilities.

Future trends in CUPS prevention and management

The field of Corrosion Under Pipe Supports (CUPS) is evolving with the incorporation of new technologies and advanced approaches. Innovations in materials science, such as advanced corrosion-resistant alloys and composite materials, are significantly enhancing the durability of pipes in hostile environments. These material improvements are complemented by more sophisticated inspection technologies, such as phased array ultrasonics and laser scanning, which provide detailed and accurate assessments, even in hard-to-reach areas.

Predictive analysis, powered by artificial intelligence (AI) and data analytics, is transforming CUPS management. AI algorithms analyze historical inspection data and environmental sensor readings to predict potential failures, allowing companies to schedule preventive maintenance more proactively. The use of digital twins facilitates real-time monitoring and simulation of corrosion processes, improving response and prevention capabilities.

Collaboration among regulatory bodies, standards organizations, and research institutions is key to updating best practices and industry standards, such as API 570 and ASME B31.3. Additionally, ongoing research is focused on developing new coating solutions and advanced cathodic protection methods to mitigate CUPS, ensuring safer and more efficient operations.

Conclusion

Effective management of corrosion under pipe supports (CUPS) is critical to ensure the integrity, safety, and efficiency of industrial systems. Corrosion under pipe supports (CUPS) can cause serious structural damage, costly repairs, and safety risks, it is important that professionals adopt best practices, such as regular inspections, the use of advanced detection technologies, and the implementation of preventive measures. Proactive management, supported by ongoing research, technological advances, and training, is vital to reduce CUPS risk, improve operational reliability, and minimize environmental and economic impacts.

¡Invest in CUPS prevention and protect your systems!

References

- Fontana, M. G., Corrosion Engineering, McGraw Hill Education (India) Pvt, Ltd, New Delhi (2016).

- R. W. & H. H. Uhlig, Corrosion & Corrosion Control, John Wiley & Sons, Inc, USA (2008).