Table of Contents

- What are API pump standards?

- API 610 Key requirements

- API 674: Reciprocating Positive Displacement Pumps

- API 676: Rotary Positive Displacement Pumps

- API 682: Shaft Sealing Systems Standard

- API 685: Seal less centrifugal pumps standard

- Future trends in API pump standards

- API vs ANSI pump standards: Key differences

- Comparative Analysis: API 610 vs ANSI B73.1

- Conclusions

- References

- Frequently Asked Questions (FAQs)

- What is the difference between API 610 and API 685 pumps?

- When should I use API pump standards instead of ANSI standards?

- What are the main types of pumps covered under API 610?

- How often are API pump standards updated?

- What is the typical service life of API 685 seal less pumps?

- Can API pump standards be used for non-petroleum applications?

- What seal plan should I use for my API 610 pump?

What are API pump standards?

API pump standards are technical specifications developed by the American Petroleum Institute (API) that establish minimum requirements for the design, manufacture, testing, and operation of pumps used in petroleum, petrochemical, and natural gas industries. These standards ensure reliability, safety, and operational efficiency in critical process applications where equipment failure could result in significant safety hazards, environmental damage, or production losses.

The API has developed multiple pump standards, each addressing specific pump types and applications:

- API 610: Centrifugal pumps for petroleum, petrochemical, and natural gas industries

- API 674: Positive displacement pumps – reciprocating

- API 676: Positive displacement pumps – rotary

- API 682: Pumps – shaft sealing systems for centrifugal and rotary pumps

- API 685: Sealless centrifugal pumps for petroleum, petrochemical, and gas industry services

These standards represent industry best practices accumulated over decades of field experience and engineering development.

| Configuration | Type / Designation | Main Characteristics | Typical Applications | Key Advantages | Flow / Pressure Range |

| Overhung Pumps (OH) Impeller mounted in overhung position beyond bearings. | OH1 – Single-stage, foot-mounted | Base-mounted, overhung impeller, foot support. | General refinery services, low to medium pressure. | Simple design, easy maintenance, cost-effective. | Flow: up to 5,000 GPM Pressure: up to 300 PSI |

| OH2 – Single-stage, centerline-mounted | Centerline-mounted, improved thermal alignment. | High-temperature services (up to 750 °F): hot oil circulation, thermal fluids. | Minimizes thermal growth and piping stresses. | Pressure: up to 750 °F / 300 PSI approx. | |

| OH3 – Two-stage, foot-mounted | Two-stage, foot-mounted design. | Higher-pressure services. | Provides higher head than OH1. | Pressure: up to 650 PSI | |

| OH4, OH5, OH6 | Special configurations, including vertical in-line designs. | Special applications requiring vertical mounting. | Compact and application-specific solutions. | Varies by design. | |

| Between Bearing Pumps (BB) Impellers positioned between two bearings for higher shaft stability. | BB1 – Single-stage, axially split casing | Axially split casing (horizontal split). | High flow, low to medium pressure. | Easy internal access, double volute reduces radial loads. | Flow: 500–20,000+ GPM Pressure: up to 750 PSI |

| BB2 – Single-stage, radially split casing | Barrel-type radial split casing. | High-pressure services (boiler feed, injection). | Superior pressure containment, reduced casing stress. | Pressure: up to 5,000 PSI | |

| BB3 – Two-stage, axially split casing | Two-stage, axially split casing. | Medium pressure with higher head requirements. | Combines BB1 benefits with multistage capability. | Pressure: up to 1,500 PSI | |

| BB4 – Multistage, radially split casing | Multistage barrel-type (radial split) casing. | Very high-pressure services. | Highest pressure capability per API 610. | Pressure: up to 10,000+ PSI | |

| BB5 – Multistage, axially split casing | Multistage axially split casing. | Pipeline pumping, water injection. | Better internal access than BB4. | Medium pressure, high head. | |

| Vertically Suspended Pumps (VS) Vertical pumps for limited space or tank-bottom suction. | VS1 – Single-stage, separately coupled | Single-stage, separately coupled design. | Sump drainage, tank-bottom pumping. | No priming required, compact footprint. | Varies by application. |

| VS2 – Single-stage, close-coupled | Single-stage, close-coupled (rigid connection). | Similar to VS1, for limited space installations. | Reduced cost, simplified installation. | Varies by application. | |

| VS3–VS6 – Multistage | Multistage configurations. | Deep sump services, higher head applications. | Adaptable to depth and head requirements. | Varies by design. |

API 610 Key requirements

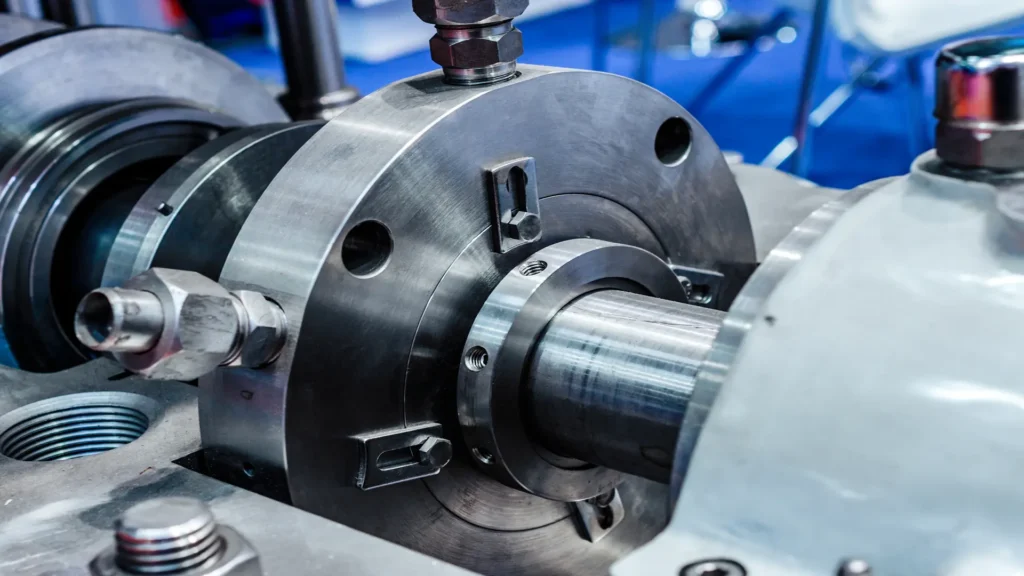

The API 610 standard establishes comprehensive requirements that ensure pump reliability and performance in critical service applications. Baseplate design must utilize robust construction with adequate stiffness to maintain precise alignment between pump and driver throughout all operating conditions, preventing misalignment-induced failures.

The bearing housing design incorporates provisions for adequate cooling and lubrication, whether through oil bath, oil mist, or grease lubrication systems, ensuring bearing temperatures remain within acceptable limits during continuous operation.

Shaft design follows rigorous engineering principles, with minimum L3/D4 ratio requirements established to prevent excessive shaft deflection that could lead to premature seal and bearing failures. These ratios ensure adequate shaft stiffness relative to the unsupported span length and diameter.

Mechanical seal chambers conform to standardized dimensions specified in API 682, ensuring interchangeability of seal designs between manufacturers and facilitating proper seal flush arrangements.

Vibration limits are strictly defined with specific acceptance criteria measured at various operating points throughout the performance curve. These limits ensure smooth operation and long component life by preventing resonance and excessive dynamic forces.

Pressure testing requirements mandate hydrostatic testing at 1.5 times the rated pressure, verifying casing integrity and identifying any potential leak paths before the pump enters service.

Material requirements specify minimum mechanical properties and corrosion resistance characteristics appropriate for the intended service conditions, ensuring adequate strength, ductility, and chemical compatibility throughout the pump’s design life.

API 674: Reciprocating Positive Displacement Pumps

API 674 covers reciprocating positive displacement pumps (plunger and piston pumps) used for metering, injection, and high-pressure services in oil and gas facilities.

Reciprocating pumps excel in specialized applications where their unique characteristics provide distinct advantages over centrifugal or rotary pump designs. These pumps are particularly ideal when precise flow control is required, as in metering applications where accurate chemical dosing is critical regardless of discharge pressure variations.

Their capability to generate very high discharge pressures reaching up to 50,000 PSI makes them indispensable for services where centrifugal pumps cannot develop adequate head. Reciprocating pumps operate most effectively at relatively low flow rates, typically under 500 GPM, where their positive displacement action provides efficient operation.

API 674 design features

The API 674 standard mandates robust design features that ensure reliable operation in demanding services. The power end incorporates heavy-duty construction with hardened components capable of withstanding the high cyclic loads inherent in reciprocating motion, typically including forged steel crankshafts, hardened connecting rods, and precision-machined crossheads.

The fluid end utilizes corrosion-resistant materials appropriate for the pumped fluid, with all wetted components designed as replaceable items to facilitate maintenance and extend service life without requiring complete pump replacement.

Plunger and piston designs feature precision-ground surfaces that provide long service life through minimal wear rates and excellent sealing characteristics, with surface finishes typically specified to micro-inch tolerances.

API 676: Rotary Positive Displacement Pumps

API 676 establishes comprehensive requirements for rotary positive displacement pumps including gear pumps, screw pumps, vane pumps, and lobe pumps used in petroleum and petrochemical services.

API 682: Shaft Sealing Systems Standard

API 682 is not a pump standard per se, but rather a comprehensive specification for mechanical seal systems used with API pumps (610, 676, and 685). It standardizes seal chamber dimensions, seal support systems, and installation requirements, ensuring compatibility and reliability across different pump and seal manufacturers.

API 682 seal plans

The standard defines seal support system arrangements called “Plans” that provide the proper sealing environment necessary for reliable mechanical seal operation. Plan 11 utilizes recirculation from the pump discharge through the seal chamber, providing flush flow that cools and lubricates the seal faces while purging any vapor or solids accumulation.

Plan 13 employs recirculation from the seal chamber back to the pump suction, creating a circulation path that maintains seal chamber cleanliness in services where discharge pressure provides adequate circulation driving force.

Plan 23 incorporates circulation from the pump discharge through an external cooler before entering the seal chamber, addressing applications where discharge temperature exceeds acceptable limits for seal reliability.

Plan 32 provides external flush from a separate source, introducing clean, cool fluid into the seal chamber when the process fluid itself is unsuitable for seal lubrication due to temperature, contamination, or other factors.

For hazardous services requiring additional containment, Plan 53A and 53B utilize dual pressurized seals with a barrier fluid reservoir positioned above the seal chamber, maintaining barrier fluid pressure above process pressure through the hydrostatic head of the reservoir.

Plan 54 employs dual pressurized seals with an external barrier fluid system that actively pressurizes and circulates the barrier fluid, providing enhanced monitoring and control capabilities for critical applications.

Why API 682 matters

Mechanical seal failures represent one of the most common causes of pump downtime in industrial facilities, resulting in unplanned maintenance, production losses, and potential safety or environmental incidents.

The API 682 standard addresses this challenge through multiple mechanisms. It ensures standardized seal chamber dimensions across all pump manufacturers, enabling seal interchangeability and simplifying spare parts management across facilities with diverse pump populations.

The standard establishes proper flush and cooling arrangements through its comprehensive seal plan definitions, ensuring adequate heat removal and lubrication for seal faces operating under demanding conditions.

API 685: Seal less centrifugal pumps standard

API 685 specifically addresses seal less centrifugal pumps—equipment designed to eliminate mechanical seals entirely, providing zero-emission operation for hazardous and toxic fluids.

What are sealless pumps?

Sealless pumps completely encapsulate the pumped fluid with no dynamic seal penetrating the pressure boundary. The two primary types covered by API 685 are:

Magnetic drive pumps

Magnetic drive pumps use magnetic coupling to transmit torque from the motor to the impeller without a shaft penetration through the casing, representing a fundamental departure from conventional sealed pump designs.

The magnetic drive system incorporates several critical design features that enable its seal less operation. The inner magnet assembly rotates with the impeller inside the containment shell, forming the driven half of the magnetic coupling that operates within the process fluid environment.

Canned motor pumps

Canned motor pumps integrate the motor and pump into a single hermetically sealed unit, representing the most comprehensive approach to seal less pump design. The motor rotor operates directly in the pumped fluid, which simultaneously provides motor cooling and eliminates the need for any shaft seal or magnetic coupling.

The canned motor design incorporates several specialized features that enable this integrated approach. The stator can consist of a thin-walled non-magnetic sleeve, typically constructed from high-nickel alloy or stainless steel, that separates the motor stator windings from the process fluid while allowing electromagnetic flux to pass through with minimal impedance.

Future trends in API pump standards

Industry 4.0 and smart pumps

The integration of digital technologies represents one of the most transformative trends affecting API pump standards and industrial pump applications. Industrial Internet of Things sensors enable continuous real-time monitoring of critical pump parameters including vibration, temperature, pressure, flow, and power consumption, generating unprecedented volumes of operational data that provide deep insights into equipment condition and performance.

Predictive analytics powered by artificial intelligence and machine learning algorithms process this sensor data to identify subtle patterns and anomalies that precede equipment failures, enabling AI-driven failure prediction that allows maintenance interventions before functional failures occur rather than responding to breakdowns after they happen.

Remote monitoring capabilities utilizing cloud-based condition monitoring platforms allow reliability engineers and equipment specialists to oversee pump performance across multiple facilities from centralized locations, identifying developing issues, comparing performance across similar units, and providing expert guidance to field personnel regardless of geographic location.

API vs ANSI pump standards: Key differences

Understanding when to specify API pumps versus ANSI pumps is crucial for optimizing project costs while meeting reliability requirements.

ANSI B73.1 Pump standard overview

The American National Standards Institute (ANSI) B73.1 standard covers horizontal end-suction centrifugal pumps for general chemical process applications. ANSI pumps are simpler, less expensive alternatives suitable for non-critical services.

Comparative Analysis: API 610 vs ANSI B73.1

| Aspect | API 610 Pumps | ANSI B73.1 Pumps |

|---|---|---|

| Applications | Critical services, oil refining, gas processing | General chemical processing, water treatment, HVAC |

| Design philosophy | Heavy-duty, maximum reliability, long service life | Standard duty, adequate reliability, moderate service life |

| Casing design | Centerline support, radially split or axially split | Foot-mounted, radially split |

| Baseplate | Fabricated steel, grouted, precision-machined | Stamped steel or absent (pump only) |

| Shaft design | Oversized for rigidity, minimum L3/D4 ratio | Standard sizing |

| Bearing housing | Heavy-duty, oil bath or oil mist lubrication | Grease-lubricated, lighter construction |

| Mechanical seal | API 682 seal chambers, comprehensive flush plans | Basic seal chamber, limited flush options |

| Materials | Higher grade, corrosion-resistant alloys | Standard cast iron or 316 SS |

| Interchangeability | Limited, custom-engineered | High interchangeability between manufacturers |

| Cost | 2-5x higher than ANSI | Lower initial cost |

| Efficiency | Optimized hydraulics, higher efficiency | Standard efficiency |

| Maintenance | Longer MTBF, easier maintenance access | More frequent maintenance |

| Spare parts | Manufacturer-specific | Standardized, readily available |

Conclusions

API pump standards represent decades of accumulated industry expertise and best practices for selecting, designing, and operating pumps in critical oil, gas, and petrochemical applications. Understanding the differences between API 610 (centrifugal), API 674 (reciprocating), API 676 (rotary), API 682 (sealing systems), and API 685 (sealless) standards is essential for making informed equipment selection decisions.

While API pumps command higher initial costs compared to ANSI or ISO alternatives, their superior reliability, extended service life, and enhanced safety features provide compelling value in critical applications where equipment failure could result in safety hazards, environmental damage, or significant production losses.

Proper pump selection requires comprehensive analysis of process conditions, fluid properties, operating environment, and long-term reliability requirements. By following the guidelines and best practices outlined in this article, engineers and operators can optimize pump selection, maximize equipment reliability, and ensure safe, efficient operation throughout the asset lifecycle.

References

- American Petroleum Institute (2014). API Standard 610: Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries. 11th Edition.

- American Petroleum Institute (2022). API Standard 685: Sealless Centrifugal Pumps for Petroleum, Petrochemical and Gas Industry Services. 3rd Edition.

- American Petroleum Institute (2016). API Standard 674: Positive Displacement Pumps—Reciprocating. 3rd Edition.

- American Petroleum Institute (2017). API Standard 676: Positive Displacement Pumps—Rotary. 3rd Edition.

- American Petroleum Institute (2014). API Standard 682: Pumps—Shaft Sealing Systems for Centrifugal and Rotary Pumps. 4th Edition.

Frequently Asked Questions (FAQs)

What is the difference between API 610 and API 685 pumps?

API 610 covers conventional centrifugal pumps with mechanical seals, while API 685 specifically addresses seal less centrifugal pumps (magnetic drive and canned motor types) that provide zero-emission operation by completely eliminating the shaft seal.

When should I use API pump standards instead of ANSI standards?

Use API standards for critical services involving hazardous fluids, high temperatures/pressures, continuous operation requirements, or when maximum reliability is essential. ANSI standards are adequate for non-critical, general chemical processing applications where lower cost is priority.

What are the main types of pumps covered under API 610?

API 610 covers three main categories: Overhung pumps (OH types), Between Bearing pumps (BB types), and Vertically Suspended pumps (VS types), with multiple sub-classifications based on specific design features.

How often are API pump standards updated?

API pump standards are typically reviewed and updated every 5-10 years to incorporate technological advances, field experience feedback, and evolving industry needs. The most recent API 685 update was published in July 2022.

What is the typical service life of API 685 seal less pumps?

Properly selected and maintained API 685 canned motor pumps typically achieve mean time between failures (MTBF) of 10-15 years. Magnetic drive pumps may have slightly shorter service life depending on application severity.

Can API pump standards be used for non-petroleum applications?

Yes, while developed primarily for oil, gas, and petrochemical industries, API pump standards can be applied to any critical industrial application requiring high reliability, including chemical processing, power generation, and water treatment when justified by service criticality.

What seal plan should I use for my API 610 pump?

Seal plan selection depends on fluid properties, temperature, and safety requirements. Common choices include Plan 11 or 13 for clean, low-temperature fluids; Plan 23 for higher temperatures; and Plan 53 or 54 for hazardous fluids requiring dual seals. Consult API 682 and seal manufacturers for specific recommendations.