Introduction

In the field of corrosion engineering, coupons stand out as necessary instruments to examine and manage the impacts of corrosion on materials and structures.

This article delves into the nature, types, benefits, limitations and, most relevantly, the information that corrosion coupons provide once used. Join me on this technical journey to unravel the secrets of these small but powerful instruments.

What are corrosion coupons?

Coupons are used to evaluate the corrosivity of various systems, to monitor the efficiency of corrosion mitigation programs, and to evaluate the suitability of metals for specific systems and environments.

Monitoring through the use of corrosion coupons is the simplest and most implemented means for determining corrosion and for this there are various types of coupons, depending on the objective and what you want to monitor.

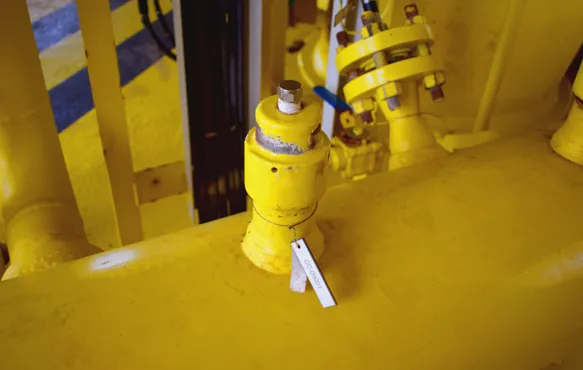

This technique does not require the use of complex procedures or equipment. Simply, a properly designed coupon and in-line coupon mounting (coupon holder) is required.

To measure corrosion, a pre-weighed coupon is inserted into the pipe, and then removed after a given period of time. The coupon is cleaned of all secondary corrosion products and reweighed. The corrosion rate of the exposed material is determined by weight difference.

Types of corrosion coupons

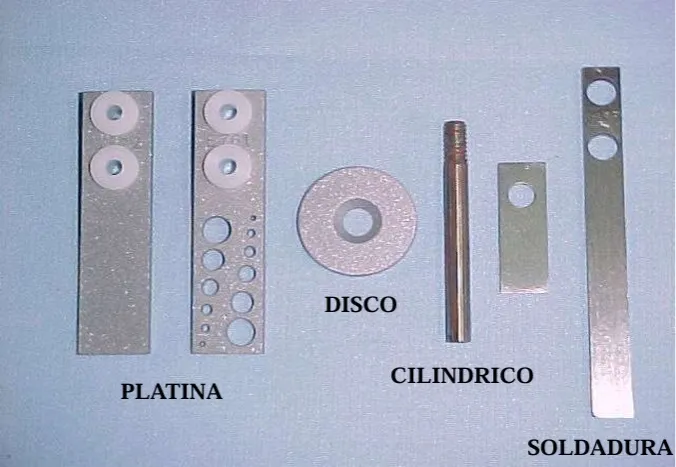

Among the main types of coupons are the following:

- Sheets or plates: They are the most common. They are weighed before and after exposure to the corrosive environment, and the difference in mass is used to calculate the corrosion rate.

- Disc Coupons: Excellent for studios where surface finish is critical.

- Cylindrical coupons: Mainly used in corrosion studies in soils or concrete, their shape allows easy insertion and extraction of the medium under study.

- Welding coupons: Used to determine and demonstrate weld quality.

Benefits of corrosion coupons

- Ease of use: It is not necessary to use electronic devices for monitoring.

- Flexibility: This methodology is remarkably flexible, since it allows the manufacture of coupons from any type of alloy found on the market. Furthermore, by using specific geometric designs, it is possible to investigate a variety of corrosive environments.

- Universality: This technique is suitable for a wide range of environments, covering both corrosive and erosive agents, including gases, liquids and solids, as well as flow and stagnation situations.

- Reliability: The coupons are free of common interferences that can cause erroneous measurements, corrosion or probe failure.

- Visual inspection: Allows inspections to be carried out both with the naked eye and at a microscopic level.

- Specific Corrosion Detection: Facilitates the identification and evaluation of specific types of corrosion, such as pitting corrosion.

- Surface examination: Enables detailed observation and analysis of deposits that form on surfaces.

Limitations and disadvantages of corrosion coupons

Although corrosion coupons are valuable tools in corrosion engineering, it is crucial to recognize and understand their limitations to correctly interpret the data they provide and to improve corrosion mitigation strategies.

The main limitations of corrosion coupons are detailed below.

- Delayed information: Typically, in a standard monitoring scheme, coupons need to be exposed for three months to a year before being removed for laboratory analysis. This means that knowledge about a corrosive incident is acquired well after its occurrence.

- Temporal indeterminacy: In the event that a corrosive incident occurs during the time that the coupon is displayed, it does not have the ability to specify at what specific time the event occurred.

- Time average: The ability of the coupon to reflect the maximum corrosion rate of a particular event depends on the intensity and duration of that event. Therefore, it may not adequately reflect the peak corrosion rate, and short events may not show a significant increase in weight loss.

- Isolation from galvanic corrosion: Generally, coupons are designed to be isolated from any direct metal-to-metal contact. This implies that they are not influenced by galvanic interactions that could be occurring in the system.

What corrosion coupons reveal

Corrosion coupons reveal valuable information about the nature and rate of corrosion in a specific system. Here are more details on what they can reveal:

- Corrosion rate: Coupons provide a quantitative measure of how quickly a material degrades in a specific environment. This is crucial for predicting component life and planning preventive maintenance.

- Type of corrosion: Coupons can show different corrosion patterns, such as uniform corrosion, pitting, intergranular, galvanic, among others. Identifying the type of corrosion is essential for selecting appropriate materials and protection strategies.

- Effectiveness of inhibitors: By comparing coupons exposed in environments with and without corrosion inhibitors, the effectiveness of different treatments can be evaluated and the most suitable one for a particular system can be selected.

- Environmental conditions: Changes in corrosion rates may indicate variations in environmental conditions, such as the presence of contaminants or changes in the chemical composition of the medium.

How many coupons should be implemented in a system?

Generally, in a specific observation point for coupon monitoring, it is recommended to install more than one coupon for several important reasons:

- Uncontrollable factors: In any industrial or natural environment, there are numerous variables that can affect the accuracy of a single coupon’s measurements. These variables include fluctuations in environmental conditions, changes in the chemical composition of the media, and variations in flow rates, among others. By using multiple coupons and averaging your results, you can mitigate the impact of these uncontrollable factors. This not only improves the reliability of the data collected, but also increases the precision of the measurements, providing a more reliable representation of the corrosion rate.

- Evaluation of pre-existing corrosion: Coupons are indicative of corrosion that has occurred up to the time of recovery. However, to gain a more detailed understanding of how the corrosion rate may have varied over time, it is useful to deploy multiple coupons at the same monitoring point. These coupons can be withdrawn at predetermined intervals. For example, one can be recovered after three months, another after six months, and another after a year. This approach allows engineers and maintenance technicians to track and analyze corrosion trends over time, providing a more dynamic and detailed view of how corrosion has impacted the material in question.

- Compare and contrast: By using multiple coupons at a single monitoring point, engineers have the opportunity to compare results between coupons. This can be particularly useful if the coupons vary in material, coating, or surface treatment. By comparing how different coupons respond in the same environment, valuable inferences can be made about which materials or treatments are most resistant to corrosion in that specific environment.

Implementation and management of programs with corrosion coupons

Strategic implementation and proper management of corrosion coupon monitoring programs are essential to obtain representative data and make informed decisions about the integrity of industrial assets.

Specialized asset integrity companies, such as Axess Group, offer expertise and comprehensive services for the design, installation and analysis of corrosion monitoring programs that include the use of corrosion coupons. Their expertise in selecting the optimal coupon location, adherence to installation best practices and interpretation of results contribute to the effectiveness of this technique for corrosion prevention and control.

Conclusion

In conclusion, corrosion coupons emerge as fundamental tools in the field of anticorrosive engineering , offering a window into the corrosive behavior of materials and structures in various environments.

By using them, accurate and detailed measurements of the rate and type of corrosion can be obtained, which is essential for effective maintenance planning and the selection of appropriate protective materials and treatments.

Despite their limitations, such as delay in obtaining results and inability to capture specific corrosive events in real time, corrosion coupons remain an economical and reliable option for monitoring and understanding corrosion.

Deploying multiple coupons at a single monitoring point not only improves measurement accuracy and reliability, but also provides a richer, more detailed view of how corrosion affects materials over time. This allows for more informed and strategic decision making regarding corrosion protection and preventive maintenance.

References

Own source