Introduction

Enhanced Oil Recovery (EOR) in hydrocarbon production involves continuous efforts to maximize oil extraction from reservoirs. Throughout the life cycle of a well, the natural production rate decreases, making it necessary to apply methods that stimulate the reservoir to maintain production at optimal levels. These practices are adapted according to the stage of well development, the geological properties of the formation and the economic viability of the operations.

To achieve effective recovery, various Enhanced Oil Recovery techniques are employed; there are three main techniques that include: gas injection, thermal injection and chemical injection. These are necessary for the extraction of remaining oil in increasingly complex reservoirs. The selection and implementation of these strategies prolong the productive life of oil fields and optimize the use of natural resources.

Understanding Enhanced Oil Recovery (EOR)

The EOR process, also known as tertiary recovery, is a method that uses advanced techniques to alter the original properties of the oil and improve the extraction of oil fields when they reach their limits. These techniques are usually used after secondary extraction, but in reality they can be applied at any stage of the development or productive life of a reservoir.

EOR methods not only improve oil displacement and fluid flow within the reservoir, but also restore formation pressure; by optimizing natural forces in oil fields, these methods allow more effective mobilization and recovery of crude oil than traditional oil extraction techniques.

The three main types of EOR operations are chemical injection (using alkaline substances, micellar polymers or surfactants), gas injection (using carbon dioxide, natural gas or nitrogen) and thermal recovery (steam injection, cyclic steam stimulation and in situ combustion). Each type depends on temperature, pressure, depth, permeability, residual oil saturation, porosity, and reservoir fluid properties such as API gravity and viscosity1.

The following video shows an overview of the process of enhanced oil recovery techniques. Video courtesy of School of Engineering 101.

Enhanced Oil Recovery (EOR).

Benefits of EOR

Enhanced Oil Recovery (EOR) comprises advanced methods that increase oil extraction beyond primary and secondary recovery techniques, being necessary due to the high demand for this fossil resource and the difficulty in extracting complex reservoirs.

The benefits of EOR include significant increases in oil recovery, which can be up to 70% higher than traditional methods, longer oilfield life, sometimes extending their life by decades, reduced environmental impact by reducing the amount of water and energy needed for extraction, greater economic benefits and integration of new technologies in the processes, as well as improved energy security globally.

The importance of these benefits lies in underlining the need to persist in the promotion and research of EOR techniques in order to maximize the productivity and sustainability of the oil industry. Adopting advanced practices wherever possible ensures an energy efficient and environmentally friendly future.

Keys to Successful Enhanced Oil Recovery (EOR)

For EOR to be successful, it is critical to understand the geology and chemistry of the reservoir. Selection of the appropriate EOR method should be based on a detailed analysis of the oilfield characteristics, including crude oil viscosity, reservoir porosity and permeability, and temperature and pressure conditions. Several keys to successful enhanced oil recovery are described below:

- Proper technique selection: There is no one-size-fits-all solution for all oilfields. The most effective EOR technique will depend on the specific reservoir type and crude oil characteristics.

- Reservoir characteristics: Analyze the geological properties of oil fields, including rock type, porosity and permeability.

- Oil properties: The composition and viscosity of the oil greatly influence the choice of technique as well as the depth at which it is found.

- Technology and innovation: Knowing the continuous advances in EOR technologies, in order to select the most effective technique, improves the efficiency of enhanced recovery.

- Economic feasibility: An economic study is required prior to the selection of enhanced recovery techniques, as the cost must be justified by the amount of additional oil recovered.

- Project design and planning: The implementation and application of a good design is fundamental to maximize efficiency and return on investment.

- Monitoring and evaluation: Continuous monitoring of the EOR process is necessary to assess its effectiveness and make adjustments as needed.

Innovations in Enhanced Oil Recovery (EOR) techniques

Research and development in the field of EOR has resulted in significant advances in recent years. Some of the developments include:

Nanotechnology: In this technique, nanoparticles are dispersed in a base fluid and injected into reservoirs to improve EOR efficiency. Nanoparticles decrease interfacial tension within the reservoir, increasing oil mobility and optimizing sweep efficiency. Researchers are exploring various nanoparticles, such as alumina, iron oxide and silica.

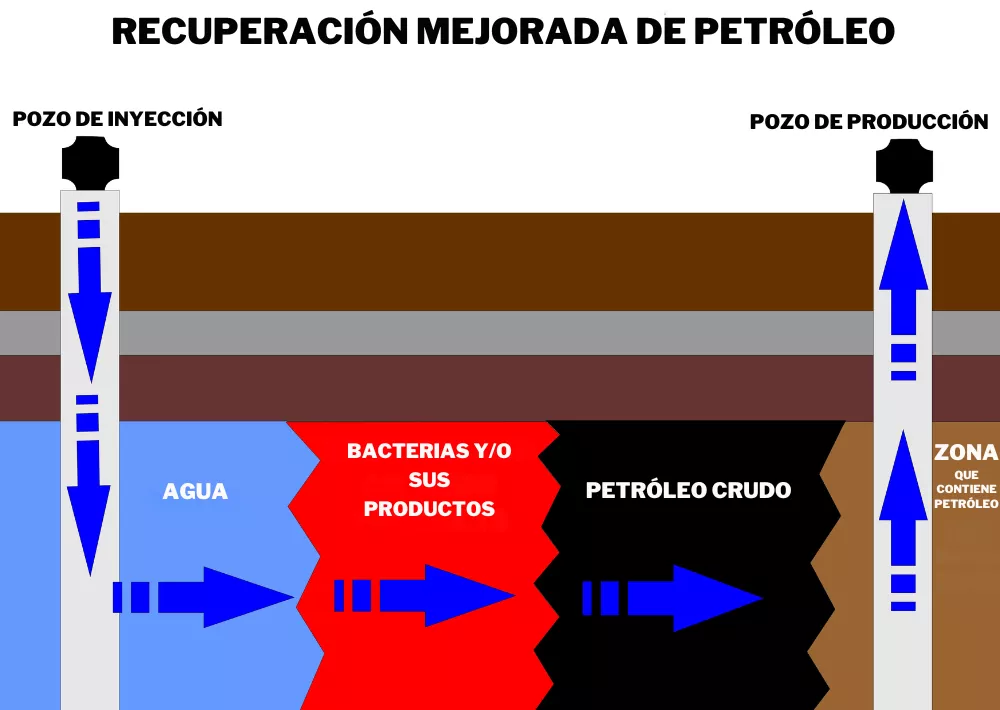

Enhanced microbial recovery for sour crude: This innovative technique injects selected microorganisms into the reservoir, as shown in Figure 1. These microbes generate enzymes capable of breaking down complex hydrocarbons, such as sulfur compounds, thus decreasing the acidity of the oil. In addition, it improves the specifications of the extracted crude and offers sustainability in the EOR for sour crude2.

Foam-assistedCO2 flooding: The emerging technique of foam-supportedCO2 flooding combines the advantages ofCO2 flooding and the efficiency of foam. When the foam is injected into the tank, it generates a solid barrier against theCO2 flow improving the sweeping efficiency. It is a particularly effective method for heterogeneous reservoirs whereCO2 is channeled through highly permeable zones, leaving untapped oil; by producing foam, it decreasesCO2 mobility, ensuring uniform oil displacement throughout the reservoir3.

Thermal EOR method: In this method, electromagnetic heating has emerged as an innovative technology, offering an effective solution for extracting crude oil from oilfields considered unproductive. The use of electromagnetic waves to heat the oil reservoir greatly reduces the viscosity of the oil, allowing it to flow freely to increase production rates.

A successful case of thermal EOR is Tar Springs in Alberta, Canada, where electromagnetic heating was used to extract heavy oil from a shallow reservoir; resulting in a clear increase in EOR rates, and the technology proved to be economically and environmentally sustainable. It was also applied in the Kern River field in California, where it successfully improved efficiency by reducing oil viscosity and improving flow4.

Use of Artificial Intelligence and Machine Learning: These digital technologies improve the planning and execution of EOR operations. By analyzing large amounts of reservoir and crude oil data, these tools offer precise control for each reservoir; optimizing the ideal injection parameters (pressure and volume) for maximum oil recovery, as well as real-time monitoring and control of the data, generating strategies for adjusting EOR operational variables.

Technological improvements in the characterization and numerical simulation of oil reservoirs contribute to the continuous advances in enhanced oil recovery techniques to know all the necessary specifications and detect which technique would be the most effective for each case.

Enhanced oil recovery market

With Carbon Dioxide (CO2): GlobalCO2 EOR market revenue is expected to exceed US$3.78 billion by 2024, evidencing steady growth by 2034. This method is key to rejuvenating mature oil fields, improving recovery rates and extending their economic life.

With the demand for environmental sustainability and regulations against greenhouse gas emissions,CO2 EOR is positioned as an essential carbon capture and storage strategy. Although theCO2 EOR market promises opportunities with expanding investment and technological innovation, it faces challenges such as volatile oil prices and the influence of geopolitical factors5.

Enhanced Oil Recovery Market Size: The enhanced oil recovery market is anticipated to grow at a compound annual growth rate of over 2% between 2022 and 2027. Gas injection, especially withCO2, will dominate this market, boosting both EOR oil production and benefiting the environment.

New oilfield discoveries in Africa and South America could offer significant near-term opportunities. Asia-Pacific, in particular, could see remarkable growth due to increased investments in the exploration and production sector and the need to apply EOR in mature oil fields6.

Conclusions

Enhanced Oil Recovery (EOR) techniques are significant in extending the life and maximizing the performance of oil fields. The effective implementation of these techniques in oilfields allows a more efficient and sustainable oil extraction, facing the difficulties of natural production decline.

By innovating EOR methods, such as gas, thermal and chemical injection, according to the specific characteristics of each reservoir, the industry is able to optimize the use of natural resources and improve the economic viability of projects. The development and application of EOR methods for advanced oil recovery are necessary to respond to the growing energy demand and environmental challenges associated with hydrocarbon production.

Continued innovation in EOR methods increase the potential and efficiency of existing oil fields, and in turn pave the way for more responsible exploitation of future oil fields, highlighting the importance of these technologies in the global energy landscape.

References

- https://glossary.slb.com/en/terms/e/eor

- Extraction techniques innovations in acid crude oil recovery; Feb 2024; FasterCapital.

- Reducing CO2 flood footprint to improve oil recovery, February 2024, FasterCapital.

- Carbon dioxide (CO2) enhanced oil recovery (EOR) market report 2024-2034; Dublin, January 2024.

- Enhanced oil recovery market share and size analysis: growth trends and forecasts (2024-2029).

- Electromagnetic heating driving enhanced oil recovery to new heights; February 2024; FasterCapital