Corrosion is a silent enemy everyone in the industry is familiar with, yet rarely fully mitigated. Whenever equipment comes into contact with an aggressive fluid or operates under demanding conditions, corrosion progresses, and its impact shows up in operating costs. In oil & gas, mining, power generation, and water treatment, corrosion often escalates into severe failures, resulting in unplanned downtime and multi-million-dollar losses.

Traditional methods, such as visual inspection, ultrasonic testing (UT), or certain electrochemical techniques, remain useful, but they share a critical limitation: they only provide point-in-time results for a phenomenon that evolves continuously, leaving operational blind spots between inspections.

High-resolution ER probes have gained relevance as a practical and reliable alternative for obtaining continuous corrosion rate indicators, without interrupting operations and with the sensitivity required to support timely decision-making.

Operating principle of ER probes

ER probes have increasingly taken center stage, not because they are new, but because they deliver something many operators have lacked for years: continuous data without shutting down the process. The principle is straightforward: when metal loses thickness, its electrical resistance increases. Measuring that change with precision is enough to track corrosion in real time. By accurately quantifying that variation, the metal loss rate can be estimated continuously.

This provides a clear advantage: operators can assess corrosion progression without stopping the process, cutting sections, or performing invasive interventions. Deviations can be detected early, enabling preventive actions before structural failures occur.

Another advantage is their robustness in harsh environments. “ER probes operate across wide pressure and temperature ranges and perform well in highly corrosive media” (Roberge, 2008). This makes them ideal for critical assets in refineries, petrochemical plants, gas facilities, offshore operations, and complex chemical processes.

Comparison with other monitoring methods

While multiple tools exist to monitor corrosion, many fall short when real-time information is required. Visual inspection and UT are effective at spotting existing or developing damage, but they do not reveal how corrosion evolves between routine checks.

Electrochemical techniques can provide detailed data, but they typically require controlled conditions or specialized equipment that is not always available in the field.

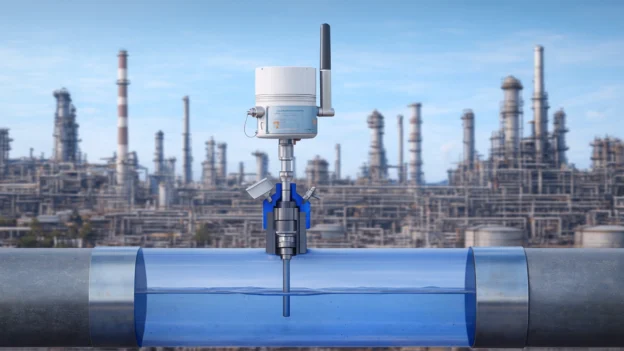

Electrical Resistance (ER) probes, on the other hand, offer a practical and efficient solution. They can be installed directly in process lines—both intrusive and non-intrusive—without halting operations, feeding data into existing systems from the moment they are installed. This allows operators to gain a comprehensive view of corrosion behavior within minutes, rather than days, weeks, or months.

Scientific evidence supports their reliability. A recent study by Martinelli-Orlando & Angst (2022) found a strong correlation between ER probe measurements and other recognized techniques, confirming their suitability even in complex environments.

Industry case studies

“In July 2021, neutralizing amine injection was interrupted, and the corrosion rate dropped significantly. In September 2021, a new injection nozzle was installed. By using Rosemount wireless corrosion and erosion transmitters and AspenTech IP.21 software, the refinery was able to prevent corrosion and ensure the durability and integrity of its piping. This also supported effective predictive maintenance and avoided unplanned shutdowns.” (Emerson, 2022)

This is a report where Emerson refers to a case from the Preem refinery in Lysekil in Sweden, where the same merited the installation of wireless sensors to detect the advance of the corrosion rate in a distillation column.

Thanks to this action, it was possible to detect in the evaluations that the problem itself was associated with an incorrect dosage of neutralizing amine during the process. And thanks to the installation of these sensors, it was possible to carry out continuous monitoring so that the equipment could correct the process before critical levels were reached, thus avoiding unscheduled shutdowns and high-cost corrective work.

Another significant case of the effectiveness and efficiency of this method can be reviewed with this example: In a gas processing plant in Alberta, Canada, the application of ER probes in gas lines and subway storage systems gave similar results. During routine inspections, variations in the sensors were detected, for which preventive measures were taken to avoid possible failures in critical components.

It is also worth mentioning a study by Martinelli-Orlando and Angst (2022) carried out in a petrochemical plant, where ER probe measurements were compared between electrochemical techniques and thickness loss in materials, obtaining good results that reinforced the use of this method in industrial environments where precision and continuity are required.

Benefits of continuous corrosion monitoring

Real-time corrosion monitoring represents a major shift in inspection and asset integrity management. It enables the early identification of material degradation, supporting preventive actions before damage becomes critical. The result is reduced operational risk and avoidance of unexpected process shutdowns.

A continuous stream of data also transforms maintenance planning. Instead of relying solely on fixed turnaround schedules, interventions can be based on asset condition. This reduces emergency repairs and improves resource allocation, extending asset life. According to Roberge (2008), continuous monitoring can increase equipment life by up to 30%.

The documentation provided by these systems is also essential for regulatory compliance. In sectors where corrosion control is mandatory, ER probes provide accurate, traceable records that can be incorporated into audits and technical reports, strengthening transparency and process documentation.

Features of Cosasco’s ER-420 Transmitter

Cosasco has pioneered ER and LPR electromechanical technology for corrosion and erosion monitoring. Intrusive systems involve installing probes directly into process lines for precise corrosion measurements, while non-intrusive systems are ideal for monitoring assets without interrupting operations—making them a practical and cost-effective option in many industrial environments.

Both system types comply with industry standards and equip operators with the tools needed to detect problems before they escalate into critical failures, improving operational safety and efficiency.

Collected data is transmitted via Microcor®, a patented global technology. ER probes return high-resolution data to an interface system that integrates with Cosasco’s data management software, providing a platform for reporting and client interaction. Data can also be transferred to the client’s IoT system or Distributed Control System (DCS).

Cosasco’s most advanced device is the ER-420 transmitter, engineered for demanding industrial environments. The unit uses a two-wire power loop for easy integration into facilities with distributed monitoring points and existing DCS systems.

It carries ATEX (SIRA 14 ATEX 2304X), IECEx (IECEx SIR 14.0107X), and CSA (Class I, Zone 1, AEx ib IIC T4 Gc, Ta = -40°C to +80°C) certifications, making it suitable for classified areas requiring high reliability. Though not necessarily the company’s exclusive “flagship product,” Cosasco also promotes additional ER instruments and probes with proven effectiveness (Cosasco.com, 2025).

Conclusions

High-resolution ER probes provide significant value. Their ability to deliver real-time data and operate under severe conditions gives them a strong advantage over traditional methods.

Documented field cases in refineries, gas plants, and petrochemical facilities confirm their utility in detection, cost reduction, and optimized maintenance—key factors that reinforce operational safety and support data-driven decision-making.

References

- Emerson. (2022). Preem Solves a Persistent Refinery Corrosion Problem Using Online Corrosion Monitoring.

- Martinelli-Orlando, F., & Angst, U. (2022). Monitoring corrosion rates with ER-probes – a critical assessment based on experiments and numerical modelling.

- Roberge, P. R. (2008). Corrosion Engineering: Principles and Practice. McGraw-Hill.

- Cosasco. (n.d.). ER Corrosion Monitoring Transmitter ER-420.