Table of Contents

- Thermal monitoring, key to industrial efficiency

- Continuous thermal monitoring in the steel industry

- Thermographic inspection: Cuatro practical solutions

- Benefits of continuous thermal monitoring

- Advanced technology for demanding industrial environments

- Proactive approach and risk mitigation

- Frequently asked questions about continuous thermal monitoring

- What is continuous thermal monitoring?

- Why is it important in the steel industry?

- What problems can this technology prevent?

- What are the main benefits of thermal monitoring?

- How is a thermal monitoring system implemented?

- What return on investment can be expected?

- What other applications does thermography have?

Thermal monitoring, key to industrial efficiency

Thermal monitoring in the steel industry has always been a pillar of industrial innovation. However, many critical processes still rely on physical inspections and scheduled maintenance strategies, increasing the likelihood of catastrophic equipment failures.

Monitoring applications for ladles and electric arc furnaces (EAF), for example, require highly trained technicians to access the site, assess wear, and diagnose the condition of the equipment. Instead, steel manufacturers need a modern solution that allows operators to view thermal and visual data in real time from a secure, centralized location.

Continuous thermal monitoring in the steel industry

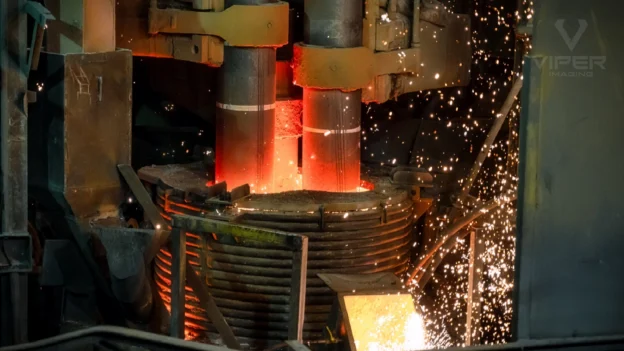

Continuous thermal monitoring solutions use advanced thermal and visual cameras to provide steel plants with 24/7 coverage of ladles, electric arc furnaces, and other critical equipment. Prioritizing key equipment for thermal monitoring is essential to maximizing reliability and safety in plant operations, backed by Viper Imaging technology.

With greater visibility into the actual condition of assets, steel plants can reduce the risk of breakouts, optimize maintenance schedules, and improve workplace safety. Integrating thermography with other maintenance technologies, such as vibration analysis or ultrasound, provides a more comprehensive view of asset condition.

Integrating all maintenance data into a single computer system allows for the generation of unified reports and optimizes decision-making for asset management.

Thermographic inspection: Cuatro practical solutions

Thermographic inspection, as part of a predictive maintenance strategy, can generate significant cost savings by reducing unplanned downtime and minimizing operating expenses:

1. Mitigating the risk of ladle breakouts

Ladles are critical for transporting and refining molten steel. However, they also present several maintenance challenges that must be addressed to ensure their safe and reliable operation. Breakouts are among the most dangerous and costly failures that can occur in steel manufacturing, and they can lead to injury or death if workers are exposed to molten materials.

Continuous Thermal Monitoring solutions reduce the risk of breakouts by providing real-time thermal data to operations and maintenance teams. Mounted thermal cameras measure external ladle temperature profiles to detect uneven heating or hotspots that may indicate refractory degradation.

Maintenance technicians analyze thermal images from these cameras to identify potential issues before they escalate. Instead of waiting for an inspection, Operators can immediately stop production and initiate a repair. Early detection through thermal monitoring helps avoid costly emergency repairs.

2. Optimizing relining intervals

Determining the optimal relining frequency is a complex and imprecise science that varies based on several factors. Relining too often increases costs and leads to unnecessary downtime, while delays can lead to degradation of the refractory lining and breakouts.

Continuous Thermal Monitoring provides real-time data on refractory wear, hot spots, and operational efficiency. Instead of relying on rough estimates, steel plants can optimize relining schedules based on the actual condition of the refractory lining.

Scheduling maintenance based on real-time data is a key part of an effective maintenance program, enabling proactive and preventive strategies that minimize unplanned outages. This allows for partial repairs in high-wear areas, extending the ladle’s service life and reducing downtime.

Optimizing relining intervals as part of a structured maintenance program helps reduce equipment repair costs by preventing severe damage and avoiding costly emergency repairs.

3. Preventing EAF Steam Explosions

EAFs have revolutionized the steel production process, offering greater flexibility, energy efficiency, and sustainability compared to traditional blast furnaces. However, they also create unique risks and operational challenges that require specialized expertise. EAFs are part of the plant’s critical infrastructure and require advanced monitoring to ensure safe and reliable operation.

Water-cooled panels prevent the furnace shell and roof from overheating, while other cooling systems protect critical components such as the transformer, hydraulic actuators, and electrodes. Even small leaks can trigger a steam explosion, resulting in injuries, production shutdowns, and costly repairs.

Thermal sensors monitor the EAF shell, roof, panel, and electrode temperatures to provide early warning of water leaks from the cooling system. These condition monitoring sensors provide valuable data on equipment health by continuously assessing temperature changes and correlating measurements to identify potential issues.

The sensors automatically detect a sudden or localized temperature drop that could indicate a leak, initiating an emergency shutdown to prevent water from reaching the molten steel. Early detection of leaks helps avert safety hazards for workers.

4. Detecting furnace wall failure

The refractory lining of the EAF wall is repeatedly exposed to extreme temperatures. Each heat cycle expands and contracts the lining, weakening its structure and leading to localized failures. Thermal anomalies detected by sensors can indicate early signs of wear, allowing for timely intervention. Similarly, molten slag can react with the lining and break down protective materials.

Thermal sensors continuously track furnace wall temperatures to detect hot spots and signs of localized wear. Operators can use this data to identify thin refractory zones before they lead to collapse, shut down the EAF, and conduct partial repairs to the affected panels.

By comparing heat signatures over time, operators can identify abnormal patterns that may signal the development of issues. As heat-producing friction develops in worn areas, temperature increases can be detected early with thermal monitoring.

Benefits of continuous thermal monitoring

Continuous thermal monitoring provides critical information about the thermal behavior of industrial equipment. The following sections detail the main benefits and applications of these technological solutions.

Real-time data and predictive maintenance

Viper Imaging’s continuous thermal monitoring solutions provide operators with real-time temperature data, enabling them to proactively identify faults and take corrective action before catastrophic failures occur.

Predictive maintenance and preventive maintenance are key components of modern maintenance programs that use thermal monitoring sensors to monitor equipment performance, minimize unplanned downtime, and improve overall asset reliability.

Gradual implementation in the steel industry

Many steel manufacturers start by deploying cameras to monitor a specific asset or production process. This pilot project helps their personnel become familiar with the solution’s features and capabilities before expanding into additional facilities or applications.

Common thermal monitoring applications in steel mills:

- Ladle Refractory Lining

- Electric Arc Furnace

- Water Wall Leak Detection

- Ladle Metallurgy Furnace

- Continuous Casting

- Reheat Furnaces

- Coke Plant

- Substation Monitoring

- Basic Oxygen Furnace

- Argon Oxygen Decarburization

Return on investment and maintenance optimization

A strong maintenance investment strategy includes tracking total maintenance costs and maintenance dollars to assess the return on investment of predictive and preventive maintenance programs. According to the federal energy management program, organizations that monitor and analyze these costs can achieve significant cost savings and improved return on investment (ROI) by implementing advanced maintenance technologies.

Predictive maintenance programs and preventive maintenance programs help save money by reducing maintenance fees, unplanned downtime, and unplanned equipment failures. By utilizing maintenance technologies such as motor circuit analysis, additional thermal imaging, and thermal monitoring sensors, organizations can improve machine asset availability and enhance the performance of monitoring equipment.

Data integration and the role of technical staff

Integrating all maintenance data into a unified computer system enables the seamless sharing of information. In contrast, maintenance technicians and human resources play a crucial role in implementing these strategies and ensuring the effectiveness of maintenance programs.

Transitioning maintenance resources from reactive to proactive strategies helps avoid excessive additional maintenance efforts and reduces the risk of costly engine failure. These approaches are especially valuable in data centers and electrical maintenance, where continuous monitoring and proactive maintenance are essential for operational reliability and safety.

Advanced technology for demanding industrial environments

The sensors have been designed and built to withstand the challenging environments typical of applications such as ladle monitoring and Electric Arc Furnace monitoring.

When asked to comment on the advancements he has seen throughout his years serving customers in the metals industry, Rich Shannon, Vice President of Sales for Viper Imaging, said, “While previous generations of thermal cameras were often unable to withstand the harsh conditions typical of steel plants, Continuous Thermal Monitoring solutions are designed and built to operate in hazardous environments. The IP67-rated enclosures keep the sensor clean, cool, and protected so that they can be deployed throughout the facility.”

Proactive approach and risk mitigation

Rather than rely on time-based physical inspections or reactive maintenance strategies, steel plants can take a proactive approach that improves asset utilization, enhances workplace safety, and mitigates the risk of catastrophic equipment failure.

To see how you can deploy Continuous Thermal Monitoring solutions in your facilities, download Viper’s white paper: Mitigating Risk in the Steel Industry – The Benefits of Continuous Thermal Monitoring.

Viper Imaging recommends ASNT Level I/II Thermography certification to strengthen your expertise in thermal monitoring. Learn more at ASNT.org.

Frequently asked questions about continuous thermal monitoring

What is continuous thermal monitoring?

It is a system that measures temperatures in real time with cameras and sensors, detecting faults before they become critical.

Why is it important in the steel industry?

It allows you to monitor furnaces, ladles, and critical equipment without stopping production, reducing risks, costs, and unplanned downtime.

What problems can this technology prevent?

Molten steel leaks, overheating, refractory failures, and steam explosions, thanks to early detection of thermal anomalies.

What are the main benefits of thermal monitoring?

Greater security, less downtime, predictive maintenance, and optimization of energy and operational performance.

How is a thermal monitoring system implemented?

It starts with a pilot project on a critical asset; then it is gradually expanded based on results and infrastructure.

What return on investment can be expected?

Savings in maintenance and unplanned downtime can exceed 25% annually, depending on the scale of the plant and the implementation strategy.

What other applications does thermography have?

Thermography is also used in electrical inspection, predictive maintenance, leak detection, process control, and structural assessment. It is also used to detect thermal anomalies in materials and components caused by internal faults, using the “lock-in thermography (LIT)” technique.