Table of Contents

ISO 9712 is an essential international standard in non-destructive testing (NDT), whose purpose is to ensure that personnel performing inspections have the necessary technical skills to guarantee quality, safety, and integrity in industrial assets.

This article analyzes how this certification applies to eddy currents (ET/ECA), its scope, the requirements for each level, and why it represents a guarantee of operational reliability and mechanical integrity. We will also explore comparisons between methods, integration with other international codes and standards, and future trends that mark the evolution of this field.

Editorial note: In technical literature, Foucault currents are also referred to as induced currents or Eddy Currents (ET/ECA), depending on the country or standard. All these terms describe the same principle of electromagnetic induction applied in NDT.

What is ISO 9712 and why is it key in NDT?

The international standard ISO 9712 is a document issued by the International Organization for Standardization (ISO) that establishes the requirements for the qualification and certification of personnel who perform non-destructive testing (NDT) in various industrial sectors.

The certification system defined in the standard is also applicable to other NDT methods or techniques, provided they meet certain criteria. Specifically, the method or technique must be supported by a comprehensive certification scheme and be recognized by international, regional, or national standards. Alternatively, its effectiveness must have been demonstrated and accepted by the relevant certification body.

Its objective is to ensure that inspectors have the technical skills necessary to perform their tasks reliably. This is essential to reduce the risk of human error and, consequently, ensure the integrity and safety of industrial assets.

Why is it key in NDT?

The standard is fundamental in the NDT field because it unifies competency criteria globally. Before this standard, there were regional and national standards that hindered the mobility of professionals and the acceptance of inspection reports between countries:

- First published in the 1990s, the standard is regularly updated to adapt to new technologies and industrial needs.

- It replaced regional standards such as EN 473 in Europe, achieving a unified and internationally recognized standard.

- It is currently adopted by industries as diverse as Oil & Gas, aeronautics, nuclear, renewable energy, and petrochemicals.

As a recognized and internationally adopted standard, the regulation guarantees:

- Reliability: Inspection results are reliable, as personnel are qualified under the same rigorous system.

- Safety: Reducing human error in fault detection prevents catastrophic accidents.

- International trade: Facilitates the hiring of personnel and the validation of NDT services in global projects and contracts, such as those governed by ASME or API standards.

Essentially, the standard acts as a common language that ensures quality and safety in the industry, promoting technical excellence and trust between customers and inspection service providers.

Eddy currents in non-destructive testing

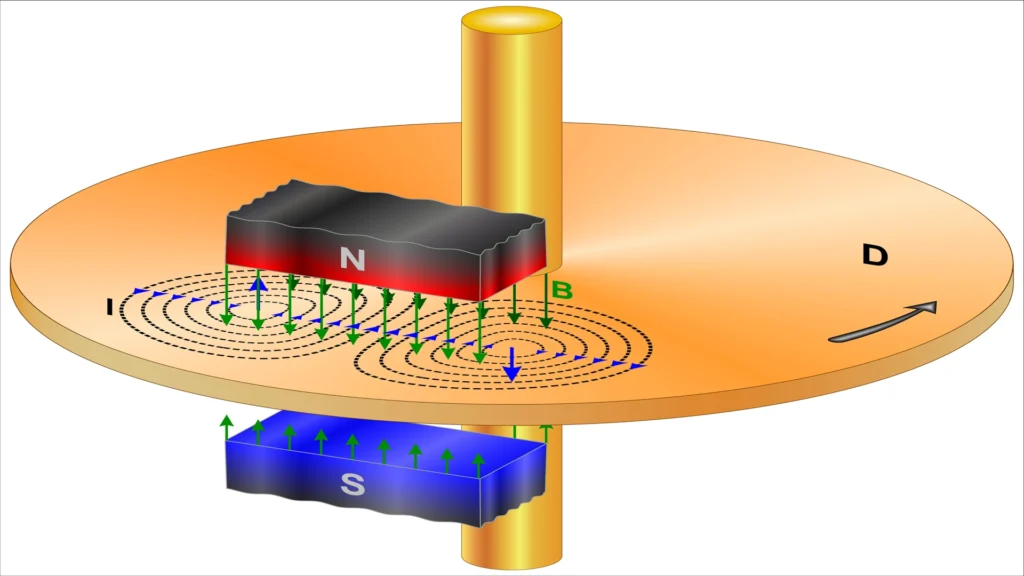

Eddy currents are an electromagnetic technique that allows surface and subsurface discontinuities in conductive materials to be detected. The physical principle is based on inducing electrical currents in the material and measuring their disturbances or discontinuities in the presence of defects or changes in properties.

Industrial applications

Eddy Current Testing (ET) is one of the ideal NDT techniques for inspecting conductive materials. Its main advantage is its high inspection speed, without the need for couplers. Although commonly used to detect cracks, its versatility goes far beyond this, allowing:

- Thickness measurement: One of the most effective non-destructive tests for thickness measurement is the use of the non-destructive Eddy Current technique (ECT). This technique is widely recognized for its accuracy, efficiency, and ability to measure non-magnetic conductive materials without physical contact.

- Verification of material properties: Identify the hardness and conductivity of metals, which is useful for classifying alloys and verifying heat treatments.

- Coating measurement: Quantify the thickness of non-conductive layers, such as paint on a metal part.

- Corrosion detection: Identify and evaluate corrosion even in internal layers of thin metals, where other techniques such as ultrasound cannot reach.

- Conductivity tests: This feature allows ferrous and non-ferrous alloys to be identified and classified, as well as verifying the effectiveness of the heat treatments applied.

- Bolt rivet inspection: To detect cracks forming inside rivets and bolt holes.

- Inspection of welds in stainless steel or non-ferrous alloy pipelines: This is the most widely used and effective technique for detecting corrosion, cracking, undermining, and breakage in the inspection of heat exchanger pipes made of stainless steel, copper alloys, or non-ferrous alloys.

- Verification of aeronautical and naval components where early crack detection prevents catastrophic failures.

ET vs. ECA: Which to use and when?

- Conventional ET (Eddy Current Testing):

- Recommended for quick, specific, and low-cost inspections.

- Ideal for simple parts or areas that are difficult to access.

- ECA (Eddy Current Arrays):

- Uses multiple coils and digital processing. Allows large areas to be mapped in less time.

- Improves the visualization of defects with graphical representation on screen.

Application example: When inspecting a heat exchanger, conventional ET can detect a defect in a specific tube, but ECA allows entire tube arrays to be analyzed with greater speed and digital traceability.

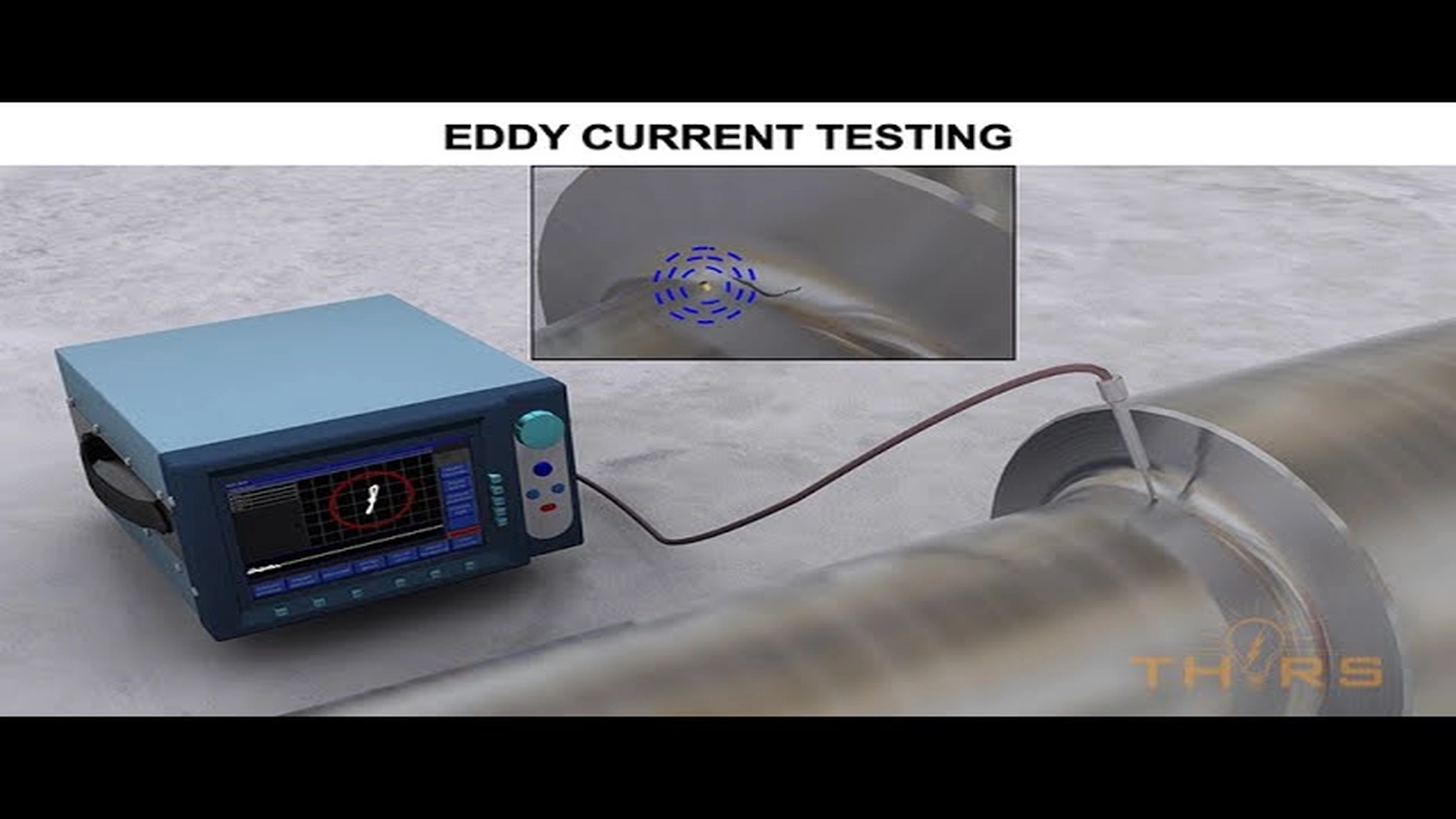

Next, we invite you to watch this video courtesy of THORS eLearning Solutions. In just a few minutes, it reviews the fundamentals of Foucault currents with clear examples and floor plans:

Competencies and certification according to ISO 9712

NDT certification under this ISO standard ensures progressive skills development, dividing the professional career in the field of NDT into three key levels.

This tiered approach ensures that each professional acquires the skills and experience necessary to take on increasing responsibilities, from performing tests to supervising and validating procedures.

Level 1 (L1)

NDT personnel certified at this level are trained to perform tests under the supervision of a higher-level technician. Their main responsibilities include:

- Preparation: Checking equipment and parts for basic tests.

- Testing: Carrying out tests according to written instructions (under supervision).

- Data recording: Recording results accurately, without requiring complex interpretation.

This level is ideal for technicians in training or those starting their career in the industry.

Level 2 (L2)

A Level 2 certified inspector has the autonomy to perform and supervise tests, as well as interpret the results. Their duties include:

- Configuration and calibration: Fully adjust equipment and parameters for testing.

- Interpretation: Analyze electromagnetic signals to identify and classify discontinuities.

- Technical reports: Prepare detailed reports with clear conclusions.

- Supervision: Guide and supervise Level 1 personnel.

A practical example of this competency is the detection and classification of corrosion in non-ferrous pipes in heat exchanger tubes within a refinery.

Level 3 (L3)

The highest level of NDT certification involves full responsibility for inspection procedures and technical management. Level 3 competencies include:

- Procedure design: Create and validate new inspection methods.

- Technical authority: Serve as the highest technical authority in audits and before regulatory bodies.

- Training: Instruct and certify lower-level personnel.

- Representation: Act as the organization’s technical liaison with authorities and clients.

A Level 3 professional can, for example, define an integrity inspection plan for a storage terminal, following complex standards such as API 653 and ASME V.

This progressive competency framework not only ensures the technical quality of inspections, but also provides a clear path for professional growth for NDT experts.

Scope and benefits of ISO 9712 certification

ISO certification in the eddy current method (ET/ECA) is not just a piece of paper; it is a strategic asset that generates benefits on multiple levels. These range from operational safety and asset integrity to professional growth and competitive advantage in the market.

Benefits for the company (owner/user)

For a company that operates industrial assets, having personnel certified under this standard is a guarantee of excellence and a pillar of its business strategy.

- Mechanical integrity and operational reliability: Certification ensures that inspections are performed to the highest technical standards, guaranteeing early detection of defects. This translates directly into the reliability of critical components, reduced downtime, and prevention of unplanned shutdowns, maintaining business continuity and protecting investment.

- Regulatory compliance and reputation: Having certified inspectors facilitates and streamlines regulatory audits and quality certifications (ISO/ASME). This not only demonstrates a commitment to the highest standards of safety and quality, but also strengthens the company’s reputation with customers, partners, and regulatory bodies.

- Competitive advantage in tenders: Having an internationally certified inspection team is a strong selling point in global tenders and contracts. It demonstrates technical capability and reliability, which can be the deciding factor in winning high-value projects with leading companies such as Chevron, Aramco, Shell, or Schlumberger.

Benefits for the professional (the technician)

For individuals, ISO 9712 certification is a passport to professional development and greater employability.

- International credential: The certification is a globally recognized credential. Unlike local certifications, this standard ensures that your skills are valued and accepted anywhere in the world.

- Increased employability: The demand for qualified NDT personnel is high, and certification to the standard is what employers are looking for. This certification opens doors to job opportunities in industries with the highest safety standards, such as petrochemicals, aeronautics, and energy.

- Path to professional growth: The level system (L1, L2, L3) provides a clear career path, allowing professionals to advance from an operational role to supervision, procedure design, and technical leadership.

Benefits for the service company (strategic)

Certification is not only a guarantee of quality, but also a fundamental business tool.

- Competitive advantage and market access: By having certified inspectors, the company stands out from the competition and can participate in tenders and projects that require compliance with international codes and standards. This opens the door to global markets and contracts with top-tier clients.

- Reliability and reputation: Provides tangible proof that staff are qualified to perform high-quality inspections. This builds customer confidence, strengthens the company’s reputation, and reduces the risk of disputes or audits.

- Risk reduction: Certified equipment minimizes the likelihood of errors in inspections, protecting the company from potential legal and financial liabilities associated with safety or asset integrity failures.

- Operational efficiency: Certified inspectors work more efficiently and consistently. This translates into less rework, more accurate reports, and better project management, optimizing resource utilization and improving profit margins.

- Talent development: The company can attract and retain the best professionals in the sector by offering a clear career development path through certification levels (L1, L2, L3). This ensures that the team is always at the forefront of the latest techniques and technologies.

ISO 9712 and its integration with other standards

The true strength of the standard lies in its ability to not be isolated, but rather a global standard that aligns and complements other international regulations and codes. This interconnection ensures that an inspector’s certification is valid for projects governed by multiple standards, eliminating technical and commercial barriers.

This synergy is evident when observing its relationship with:

- ASME Section V: defines requirements for the application of NDT in pressure equipment.

- API 653: establishes inspection guidelines for hydrocarbon storage tanks.

- ISO 55000: integrates asset management and operational reliability.

- ASTM E243: standardizes eddy current procedures.

Thanks to this interconnection, the application of this ISO document ensures that inspection results are accepted globally. This not only improves efficiency by avoiding duplicate audits, but also reduces costs and simplifies regulatory compliance in international projects.

Future and trends in ECA certification

The evolution of ISO 9712 certification is intrinsically linked to digital transformation and energy transition, setting the course for industrial inspection. These trends not only improve efficiency, but also redefine the role of the certified professional, consolidating NDT inspection as a strategic tool in modern asset management:

- Industrial digitization: integration with SCADA systems, predictive analytics platforms, and digital twins.

- Remote and automated inspection: use of drones and robots to inspect refinery equipment, pipelines, or turbines without exposing personnel.

- New energies: certification applied to hydrogen, wind energy, and large-scale battery storage.

- Artificial intelligence: algorithms that support the interpretation of ECA signals, reducing the margin for human error.

These trends strengthen the role of electromagnetic NDT as strategic tools in modern asset management. These innovations will be at the core of the presentations at the ASNT 2025 conference in October, where real cases will be presented that shape the future of electromagnetic inspection under the framework of ISO 9712.

Conclusions

ISO 9712 in eddy currents is a fundamental pillar that drives the reliability, safety, and mechanical integrity of industrial assets globally. Its progressive competency framework not only standardizes personnel qualification but also establishes a common technical language that is recognized by international standards such as ASME and API, removing barriers and facilitating trade and professional mobility.

For professionals, this NDT certification is a valuable credential that opens doors to job opportunities in the most demanding industries. For companies, it represents a strategic investment that ensures the quality of inspection services, minimizes risks, and strengthens their market position, making certification an essential requirement for operational excellence and long-term competitiveness.

References

- Evident Scientific: Eddy Current Array Tutorial

- ISO 9712:2021 Non-destructive testing: Qualification and certification of NDT personnel

- ASME Code Section V – Non-Destructive Testing.