The lignin-containing plant-based plastic developed by Professor Ho Yong Chung’s team at FAMU-FSU’s College of Engineering represents an outstanding innovation in sustainable materials. Through a method that combines this natural biopolymer with carbon dioxide, an isocyanate-free polyurethane can be synthesized, thus eliminating hazardous compounds from the process.

The new material retains the thermal, mechanical and flexibility properties of traditional polyurethane, but with more efficient manufacturing, lower energy consumption and a lower toxic load for people and the environment.

Lignin as a source of value

While cellulose has historically dominated the use of biomass biomass utilizationlignin has largely been discarded as a by-product of the paper industry. Chung’s team has given it a second life. This natural polymer, when combined with captured CO₂, becomes a viable alternative to conventional petroleum-derived plastics.

The key to the new process lies in its efficiency. By eliminating the use of isocyanates, a critical step that until now limited the sustainability of polyurethane is avoided. In addition, the resulting material dissolves easily in common solvents, facilitating processing and recycling.

Application, scalability and industrial objectives

The polyurethane developed has multiple potential applications in insulation in insulation, coatings and flexible devices. Its ability to withstand high temperatures and mechanical stresses positions it as an industrially relevant solution.

Chung stresses that the focus of the project has always been to scale the technology and bring it closer to large-scale production. Thanks to the backing of FSU and support from entities such as the U.S. Army and the South Korean government, the team is looking to transfer this knowledge from the lab to industry.

Science with purpose

The work is in line with a growing trend: replacing fossil derivatives with materials of renewable origin. In previous research, the group had already used lignin to produce polycarbonate, and now expands that horizon with a material that is even more versatile and present in everyday life.

This breakthrough not only underscores the potential of lignin as an underutilized raw material, but also positions FAMU-FSU as a reference in the development of sustainable, high-performance materials.

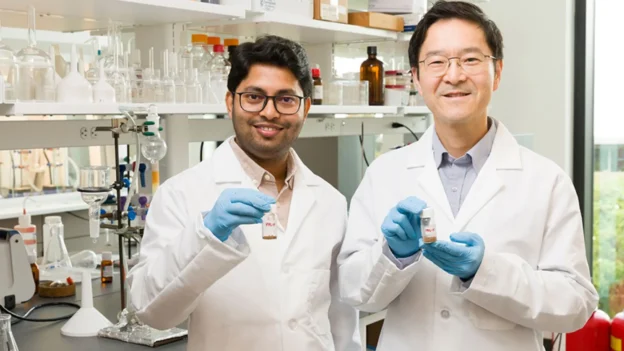

Source and photo: FAMU-FSU School of Engineering.