Modern engineering isn’t just about building things, it’s about adapting them, making them stronger, more resilient, even smarter, if you will. One of the processes that allows materials to “transform” based on their intended use and application is carburizing. Though it sounds technical, this heat treatment has quietly reshaped the design of metal parts that must endure wear, impact, and even corrosive environments. It’s precision-applied science (Davis, 2002).

But what is carburizing?

Before diving in, it’s important to clarify a commonly misunderstood point: carburizing is not the same as carburetion. The latter relates to internal combustion engines, where air mixes with fuel to power a motor. Carburizing, on the other hand, is a thermochemical treatment applied primarily to low-carbon steel to harden the surface without compromising the toughness of the core (ASM International, 1991).

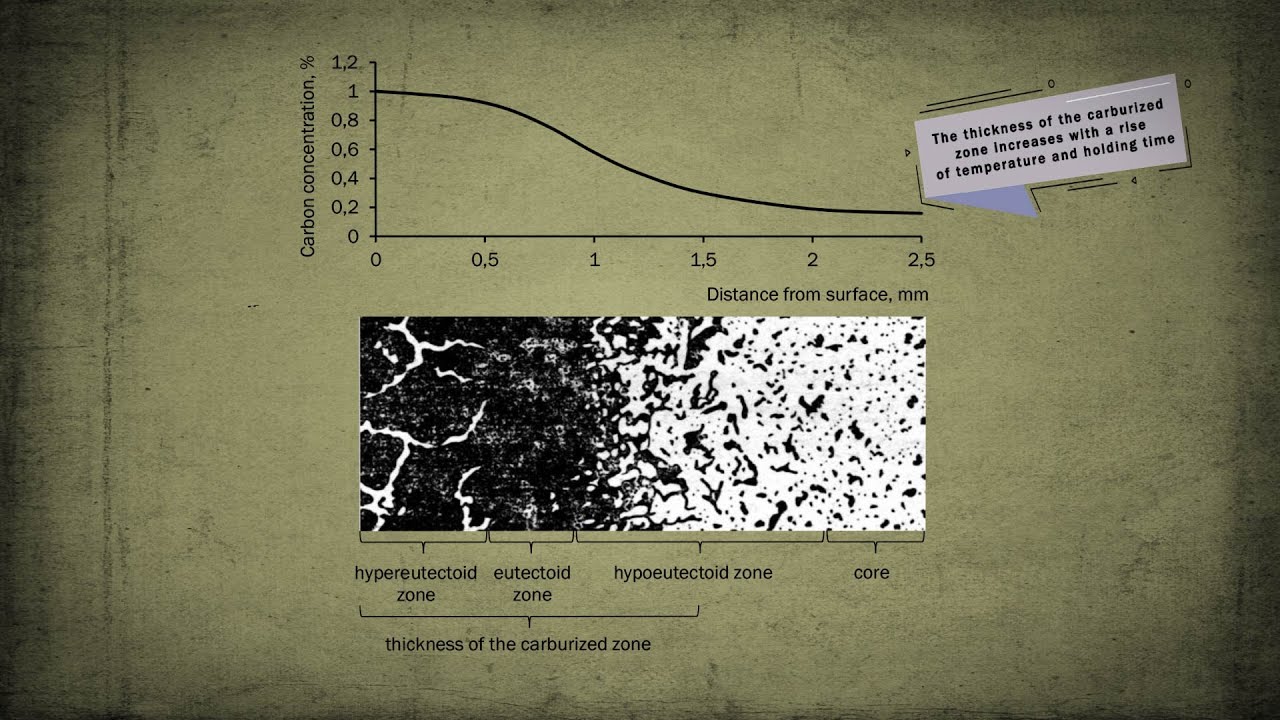

Carburizing often simply referred to as heat treatment, takes place at high temperatures (between 850°C and 950°C) in a carbon-rich environment. This environment can be gas, liquid, or even solid. Under these conditions, carbon atoms slowly diffuse into the surface of the metal, forming a much harder outer layer (Totten & Funatani, 2004).

The result is a kind of protective “shield” that enables the material to resist continuous friction, repeated impacts, and prolonged wear. That’s why it’s widely used on parts like gears, shafts, and bearings, which must perform at their best under pressure.

How does the process work?

During carburizing, the metal is exposed to a carbon-rich atmosphere. Thanks to the heat, that carbon becomes activated and begins to penetrate the surface of the metal. How deep does it go? That depends on three key factors:

- The treatment temperature

- The carbon potential of the atmosphere

- The duration of the treatment

Once the desired case depth is reached, the part is rapidly cooled, usually through quenching, which “freezes” the carbon atoms into a hard structure called martensite. This combination of a hard exterior and a ductile core offers, simply put, the best of both worlds.

Types of carburizing

Not all parts or applications require the same carburizing method. Here are some commonly used techniques:

- Liquid carburizing: Performed in salt baths (e.g., sodium carbonate), this method produces uniform surfaces and reduces oxide formation. It’s like dipping the part into a hot chemical bath.

- Vacuum carburizing: Conducted in sealed chambers or furnaces under low pressure, using gases like propane or acetylene.

- Plasma carburizing: Uses ionized gases and electrical voltages. Ideal for complex geometries, such as toothed tools or parts with internal cavities.

- Gas carburizing: The most widely used in industry. It involves gases like methane or propane and offers precise control over final hardness.

- Solid carburizing (Pack carburizing): A more traditional method where metal parts are packed in a container with charcoal and heated. Effective but less precise and more costly.

Carburization of steel: Chemical-thermal treatment.

Why is it so widely used?

When you look at the benefits of carburizing or heat treatment, it’s easy to see why it’s so prevalent in industry:

- Increased wear resistance: ideal for surfaces under constant friction, like a suit of armor.

- Reduced risk of fatigue cracks: the hardened layer delays the onset of microcracks.

- Enhanced surface hardness: crucial for gears and cutting tools.

- Tough, ductile core: allows the piece to absorb shocks without breaking.

- Improved corrosion resistance: especially in plasma carburizing.

- Geometric versatility: can be applied to complex shapes without losing uniformity.

These advantages mean carburized parts last longer, fail less, and require less maintenance—a clear win for any industry.

But it’s not perfect…

Like all things, carburizing has its downsides. Let’s take a look:

- Reduced ductility: Excessive carbon can make parts brittle if not properly controlled.

- Shape distortion: Thermal changes may affect part geometry.

- Risk of internal cracks: Especially in irregular shapes or dissimilar materials.

- Post-treatment machining challenges: Once hardened, parts are more difficult to work with.

- Grain growth: Can alter internal microstructure if temperatures aren’t managed carefully.

These drawbacks don’t disqualify the process, but they do demand precision, experience, and sound technical judgment.

Where is carburizing used?

Carburizing is present in more industries than you might think. Here are a few examples:

- Automotive: Transmission gears, camshafts, wheel axles. Carburizing allows the use of inexpensive steel and hardens only where needed.

- Aerospace: Landing gear, bearings, turbine parts—requiring hardness and resistance in extreme conditions.

- Energy: Turbines, valves, and components exposed to high temperatures and pressures.

- Agriculture: Tractors, harvesters, and gears subject to dust, mud, and variable loads.

- Heavy machinery and tools: Industrial bearings, mill shafts, cutting tools like drills and punches—all needing to withstand extreme friction.

And economically, is it worth it? Yes, but it depends on the context. Carburizing comes with direct costs: energy, specialized gases, high-temp furnaces, and control equipment. Treatment cycles can be lengthy. However, the long-term benefits, reduced maintenance, less part replacement, use of cheaper materials, and less downtime—often outweigh the initial investment.

In high-volume sectors like automotive or power generation, these savings translate into significant profits. Furthermore, modern techniques (like vacuum carburizing) help reduce energy use and allow for automated processing, increasing overall efficiency (Totten & Funatani, 2004).

Discover how Air Products drives heat treatment processes with advanced solutions in gases, equipment, and technologies. Improving productivity, reducing operating costs and raising metal quality.

Heat treatment process.

Technology, sustainability, and the future

Now more than ever, sustainability matters. Carburizing has evolved in that direction as well. Techniques like plasma or vacuum carburizing lower harmful emissions, consume less energy, and integrate seamlessly with automated systems.

With the help of sensors and control software, the process can now be monitored in real-time, ensuring consistent quality with minimal human intervention (Totten, 2017).

Conclusion

Carburizing or heat treatment is much more than just surface hardening. It gives steel a sort of dual personality: hard on the outside, tough on the inside—and that, in engineering, is pure gold. Like any advanced process, it requires knowledge, skill, and awareness of its limits. When applied correctly, it can be the key to making parts more efficient, durable, and cost-effective.

References

- Totten, G. E., & Funatani, K. (2004). Handbook of Metallurgical Process Design. CRC Press.

- Totten, G. E. (2017). Steel Heat Treatment: Metallurgy and Technologies (2nd ed.). CRC Press.

- ASM International. (1991). Heat Treater’s Guide: Practices and Procedures for Irons and Steels (2nd ed.). ASM International.

- Bell, T. (2002). Thermochemical surface engineering of steels: current status and future trends. Materials Science and Technology, 18(3), 291–301.

- Bernasconi, A., & Peroni, L. (2005). Surface hardening of steels: influence of heat treatment on residual stress and fatigue strength. International Journal of Fatigue, 27(10–12), 1408–1414.

- Davis, J. R. (Ed.). (2002). Surface Hardening of Steels: Understanding the Basics. ASM International.

- Kula, P., Pietrasik, R., & Zawadzka, K. (2008). Environmental friendly technologies in thermochemical treatment of steels. Surface & Coatings Technology, 202(14), 3335–3340.