During the third day of the PANNDT conference in Niagara Falls, the Inspenet team had the opportunity to speak with Matt Spigelmyer, site director of Vermon NDT, and Paul Holloway, president of Holloway NDT & Engineering Inc. This interview revealed a rare approach in the industry, the use of medical technologies to transform the performance of ultrasonic transducers in the industrial field.

Both experts shared how they are driving innovations in the healthcare sector towards nondestructive inspection (NDT), providing solutions that improve accuracy, reduce device size and ensure reliability on a large scale.

With an established track record in cardiology transducer design, Vermon has been able to transform its expertise in cardiology, where it designs transducers that are introduced through the veins into the heart for high-precision internal imaging, into a powerful competitive advantage in the industrial arena. This technology transfer goes beyond hardware, encompassing also design processes, customized manufacturing and innovation philosophy.

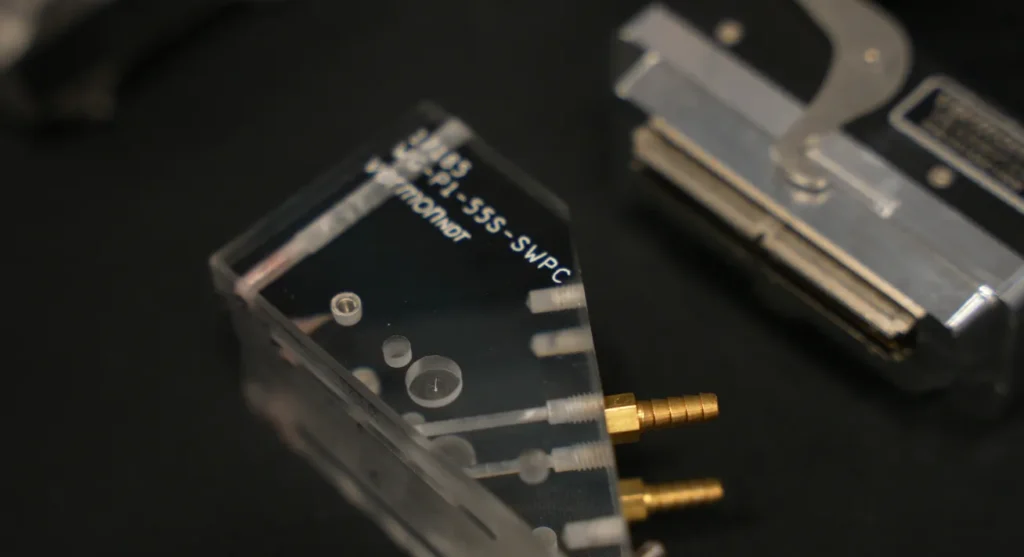

Thanks to this cross-industry synergy, the company has developed miniaturized ultrasonic transducers capable of inspecting complex industrial components, even in hard-to-reach areas, without compromising structure or image quality. This capability is especially valuable in industries such as aerospace or oil & gas, where detecting internal faults without costly disassembly or lengthy shutdowns is critical.

The key is a design philosophy focused on maximum functionality at the smallest possible size. The know-how acquired in medicine enables the company to offer tailor-made OEM solutions for non-destructive testing (NDT) demonstrating how the intersection between disciplines can generate innovations with high technological value and critical applications.

The interview also addressed CMUT (Capacitive Micromachined Ultrasonic Transducers), an emerging technology that seeks to replace or complement traditional piezoelectric transducers (PZT). A CMUT works by means of a flexible membrane suspended over a cavity that acts as a capacitor and when an electrical signal is applied, the membrane vibrates and generates ultrasonic waves; when an echo is received, this vibration produces an electrical signal that can be interpreted.

The nondestructive testing industry is interested in the potential of CMUTs for several reasons:

These benefits can translate into lighter, more portable and adaptable solutions for automated, robotic or hard-to-reach tasks. Although there are currently commercial examples of CMUTs, such as the Butterfly system for primary care, the company is committed to this development in the long term.

One of the elements that distinguishes Vermon is its ability to manufacture thousands of probes without losing uniformity, which they achieve through processes that ensure impeccable acoustic consistency, thanks to the quality standards imposed by the FDA in the medical field.

In the NDT sector, this means that each transducer delivered behaves the same as the previous one, ensuring that they all deliver the same results under the same conditions. In regulated industries, such as nuclear or aerospace, this consistency is vital for operational safety.

The partnership with Paul Holloway, a recognized expert in non-destructive testing, has been key to validate these solutions in real scenarios. Based in Canada, Holloway is leading a project to compare probes of different specifications in order to integrate the advantages of each into unique solutions. This work will result in a white paper scheduled for the end of the year, which will document the technical findings of the comparative study.

The immediate future for the company includes the launch of a new technology applied to NDT that promises to integrate high-end medical performance into industrial probes. Although details are still being withheld, Spigelmyer confirmed that this development could be available before the end of the year.

The convergence between medicine and industrial technology is opening up new possibilities in the field of ultrasonic transducers. Thanks to companies such as Vermon and the support of experts such as Holloway NDT & Engineering Inc., the nondestructive testing industry is entering an unprecedented stage of sophistication, where accuracy, customization and reliability are part of the new standard.

For more content on PANNDT 2025, visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.