Industrial AI: applied to the optimization of industrial processes

Technical overview of industrial AI applied to optimize processes, reduce variability, and improve operational stability.

Technical overview of industrial AI applied to optimize processes, reduce variability, and improve operational stability.

Technical guide on ASME B31.1 applied to the design, manufacture, inspection, and operation of power piping in power plants.

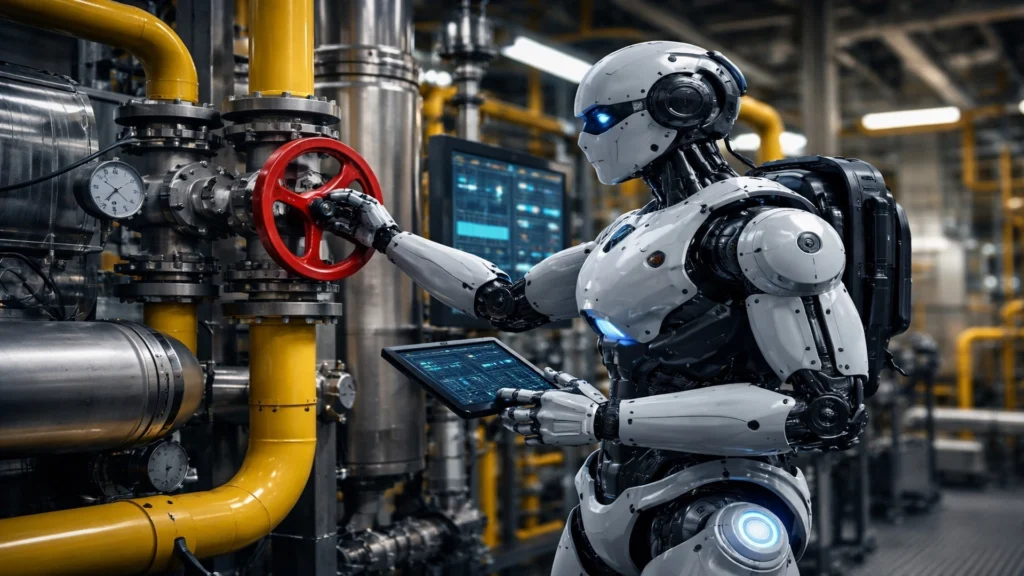

Technical analysis of industrial humanoid robots as a solution to safety, access, and maintenance challenges in energy and industrial operations.

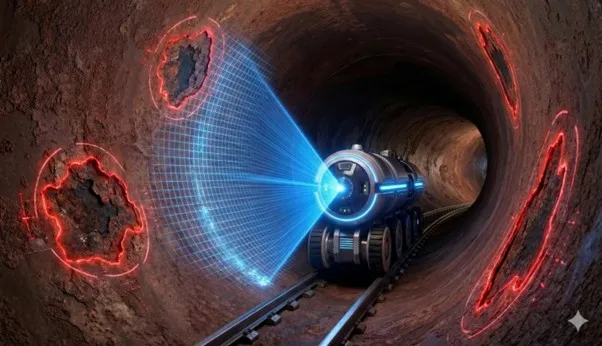

Borescopy is an NDT technique for remote visual inspections in inaccessible areas, avoiding costly dismantling of critical industrial equipment.

Pipeline integrity evolves with smart inspection technologies that enable accurate, predictive, and reliable diagnostics on industrial assets.

Condition-based monitoring transforms operational data into predictive decisions, increasing the reliability and safety of critical assets.

PAUT allows weld defects to be identified with high resolution, speed, and digital traceability, optimizing mechanical integrity in industry.

Operators guarantee safety, continuity, and efficiency in every port operation, becoming the cornerstone of operational excellence.

Pipeline welding combines technology, control, and precision to ensure industrial integrity and reliability.

The ISPS Code strengthens maritime security and maritime cyber security, protecting ships and ports in accordance with the SOLAS Convention.

ISO 9712 certifies competencies in eddy currents, key to mechanical integrity and industrial safety.

LNG is now a key component of global energy security and sustainability. Inspenet explains why it is leading the energy transition.