By: Franyi Sarmiento, Ph.D., Inspenet, December 23, 2022

A team of researchers and entrepreneurs at the University of British Columbia, UBC in Vancouver, Canada, are exploring two innovative technological approaches aimed at combating widespread plastic pollution.

The first of these is a new coating consisting of a polymer (chemical compound) that repairs itself, as happens with some animal and plant tissues. In addition, it is resistant to inclement weather.

The other material is a plastic made from algae and wood fiber that decomposes and degrades quickly (just like organic waste) after it has been used.

“Tons of plastic waste pollute our land and oceans,” says Dr. Jordan MacKenzie, co-founder and CEO of Bioform Technologies, a UBC-linked start-up that is working to bring to market a compostable bioplastic (it can be rapidly broken down by the action of living organisms, i.e. biologically).

These are the so-called bioplastics, a material produced from plant products, unlike conventional plastics, derived from petroleum.

Bioform converts seaweed and wood fiber into thin but durable bioplastic films that can be used directly to make mulch or mulch films, placed over crops to regulate soil moisture and protect them, or used to make rigid packaging products, such as beverage caps and food-carrying containers.

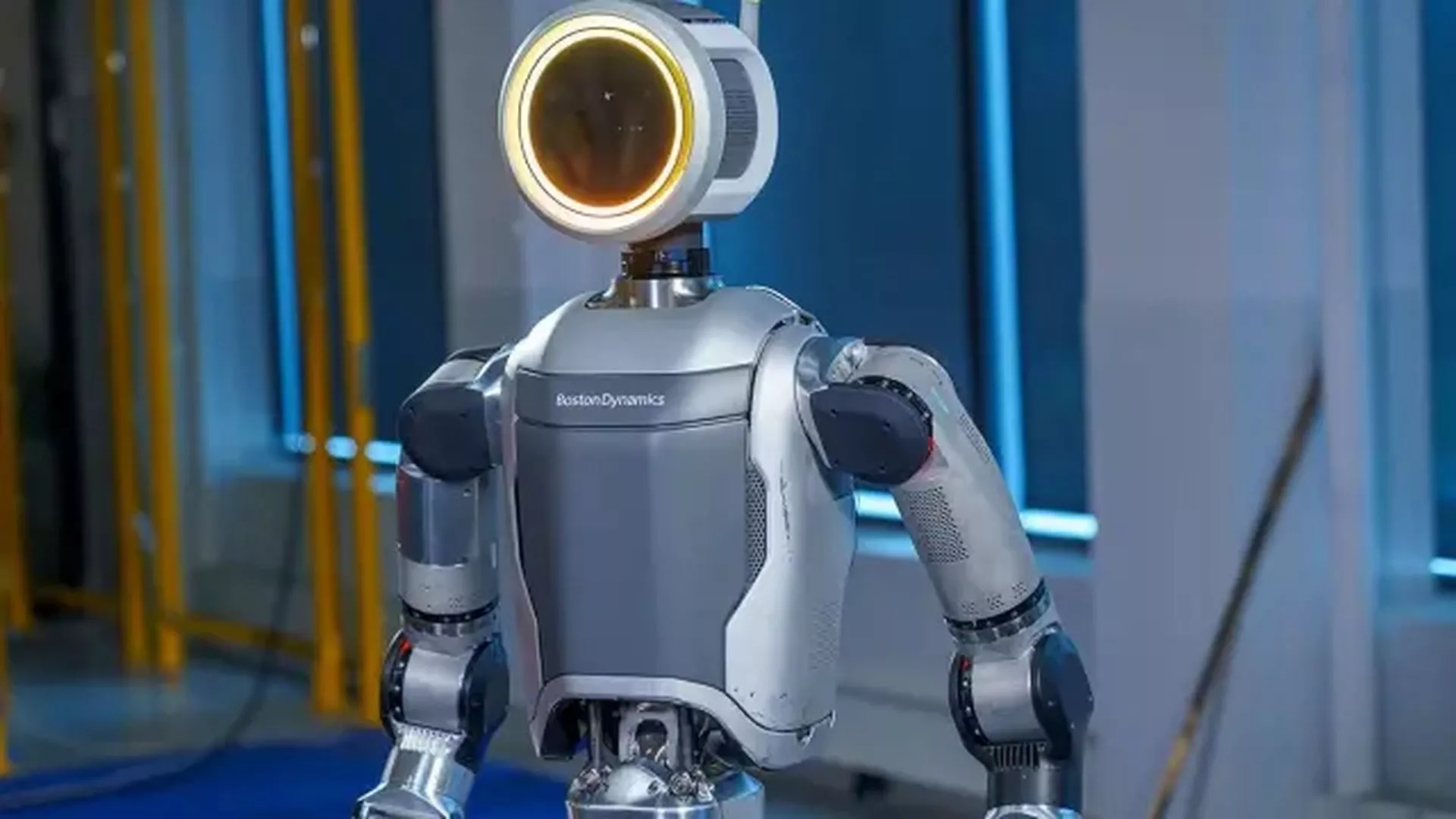

Another UBC-linked company, A2O Advanced Materials, is working on a different approach to promoting sustainability, consisting of a new class of polymers (chemical compounds) that, when added to other products, such as marine paints and industrial coatings, They manage to make them self-repairing (they repair the damage they suffer by themselves) and resistant to the elements and to variations and inclement weather, increasing their useful life.

Self-regenerating materials are already attracting the attention of battery manufacturers looking to extend the life of phones, energy storage devices and other electronics, according to A2O.

This material from the eldia.com portal was edited for clarity, style and length.

Photo: A20/Paul Jhosep/UBC Applied Science

Don’t miss the Inspenet News at: https://inspenet.com/inspenet-tv/