Author: Ph.D. Yolanda Reyes, August 10, 2022.

Introduction

Corrosion is a process of deterioration or destruction of metals that, although inevitable, can be controlled. Various methods can be used for this purpose, although the use of organic covers and/or inhibitors soluble in the corrosive medium are the commonly used alternatives due to their low costs, easy application and maintenance.

Due to the toxicity of the substances traditionally used as inhibitors of the corrosive process, there is a growing interest in the development of a series of investigations aimed at exploring efficient, economical and environmentally friendly inhibitors [1].

Various methods can be used to control the process of deterioration or destruction of metals called corrosion. The use of organic coatings and/or soluble inhibitors in the

corrosive medium are the commonly used alternatives due to low costs, easy application and maintenance.

Phosphate-based anticorrosive pigments[1-3] They are being questioned because the anion causes eutrophication in freshwater reserves and, in addition, some of them have heavy cations such as zinc or strontium, the use of which has also been restricted. Among the alternatives to totally or partially replace these pigments are metal cation benzoates, silicas exchanged with passivating ions such as cerium and lanthanum, and natural extracts, among others.

Plant extracts are a complex mixture of different, often closely related, compounds. Among them we can mention a widely distributed group in the plant kingdom, polyphenols (a family that includes tannins, flavonoids, terpenoids, among others), many of these compounds can act as organic corrosion inhibitors (Kesavan et. al., 2012). Plant extracts, as well as essential oils, are gaining more and more relevance among scientists, as they are compounds of natural origin, abundant, safe, non-polluting and accepted by the general public.

In the Oil & Gas industry, O2, H2S and CO2, etc; They are compounds that cause corrosion problems. Different industries use different ways to chemically treat pipes. Generally, the products used to prevent corrosion, such as oxygen scavengers, etc.; they have lots of chemicals and can be harmful to the environment after being disposed of.

According to research carried out, it has been determined that there are certain compounds in xerophytic plants that exert a protective action against corrosion. In this context, studies were carried out to evaluate the extracts of Opuntia Ficus Indica and Aloe Vera as possible or inhibitors of the corrosion of carbon steel (SAE 1020) in an acid medium (HCl 5% and 10%).

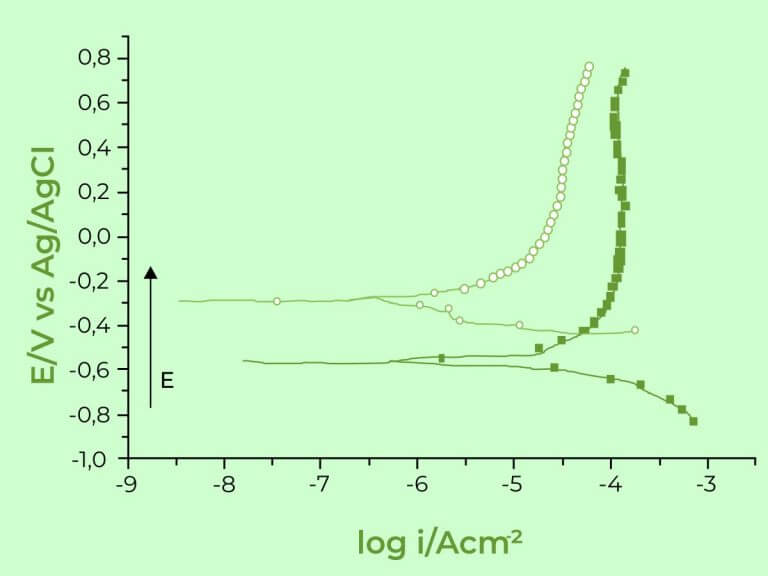

Checking the inhibitory effect of these extracts by determining the corrosion rate by electrochemical techniques of resistance to polarization and potentiodynamic curves. The results showed that for a composition of 0.4% P/V, efficiency values of 90.43% were obtained for 5% HCl, and 88.20% for 10% HCl.

Conclution

The Opuntia Ficus Indica extract has a protective effect against the corrosion of SAE 1020 carbon steel in acid environments. Of HCl at 5% and 10% (p/v) because it considerably decreases the rate of corrosion of the steel.

About the Author

Ph.D, in Electrochemistry and Corrosion, with more than 30 years of experience and a wide and versatile knowledge in Corrosion Sciences and Chemical Technology at the Academic and Industrial level. Researcher in the development of research work on Innovation and development of Electroactive Polymeric Coatings, evaluation of coatings and corrosion inhibitors and failure analysis of metallic materials. Read more